Antibacterial and dust adsorption-free spray-free PP material and preparation method thereof

A spray-free and dust-free technology, applied in the field of spray-free materials, can solve the problems of glass-based pearlescent pigments such as weak metal texture, no dust-resistant adsorption performance, and inability to completely replace spray-free coating, so as to reduce the risk of bacterial growth and improve Effect of improving service life and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

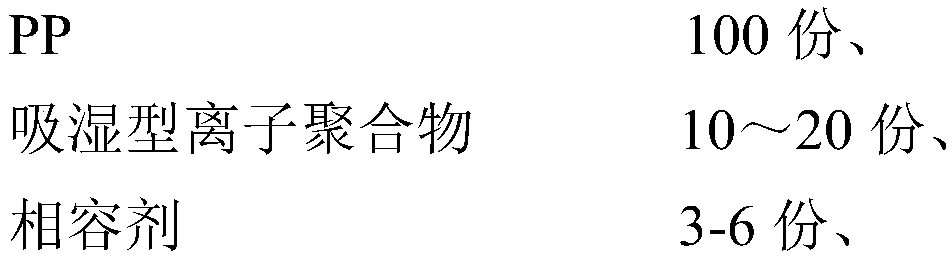

Method used

Image

Examples

Embodiment 1

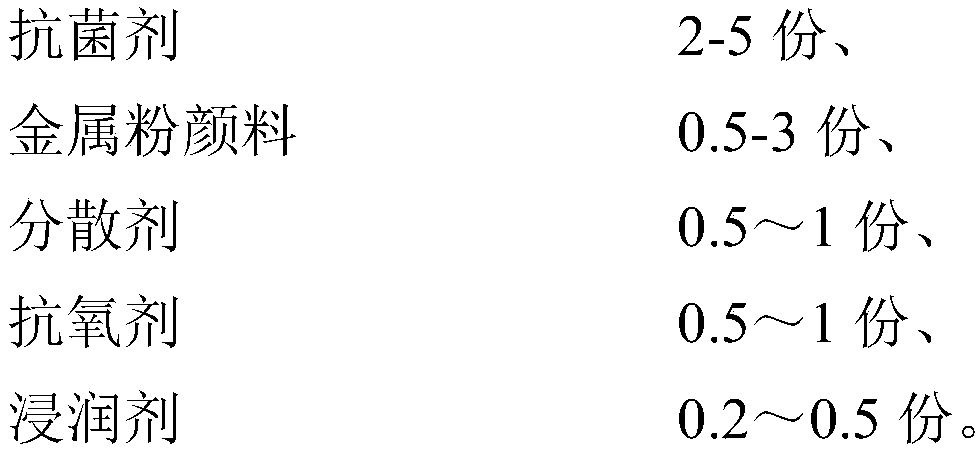

[0029] The PP in the antibacterial and dust-resistant adsorption-free spray-coating PP material of the present embodiment is a homopolymer PP, and the melt index is 12g / 10min; the hygroscopic ionic polymer is AS 500; the antibacterial agent is nano-zinc dioxide with a particle size of 100-200nm; the compatibilizer is PP-g-MAH; the metal powder pigment is aluminum silver powder with a particle size of 10 μm; the dispersant is polyethylene wax; the sizing agent is White oil; the antioxidant is a compound of hindered phenolic antioxidant and phosphite antioxidant according to the mass ratio of 1:1.

[0030] When preparing, weigh each raw material according to the weight percentage in Table 1, add PP, compatibilizer, hygroscopic ionic polymer and wetting agent into the high mixer, and mix at a speed of 300-400 rpm for 3-5min Finally, add metal powder pigments, antibacterial agents, dispersants and antioxidants, and then mix at a speed of 120-200 rpm for 2-3 minutes to form a pre...

Embodiment 2

[0032] The types of components involved in the antibacterial, dust-resistant, adsorption-free and spray-free PP material of this example are the same as in Example 1, and the preparation method of Example 1 is repeated according to the content of each component specified in Table 1, and the prepared antibacterial, dust-resistant, adsorption-free and spray-free PP The material composition is injection molded into a standard test bar according to the standard size, and the properties of the alloy are tested according to the standard, and the properties are shown in Table 2.

Embodiment 3

[0034] The types of components involved in the antibacterial, dust-resistant, adsorption-free and spray-free PP material of this example are the same as in Example 1, and the preparation method of Example 1 is repeated according to the content of each component specified in Table 1, and the prepared antibacterial, dust-resistant, adsorption-free and spray-free PP The material composition is injection molded into a standard test bar according to the standard size, and the properties of the alloy are tested according to the standard, and the properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com