Ultrahigh-temperature sterilized milk, cow milk processing method for improving stability of ultrahigh-temperature sterilized milk and application of ultrahigh-temperature sterilized milk

A technology of ultra-high temperature sterilization and processing method, applied in the field of liquid dairy products, can solve the problem that the number of breast infected somatic cells cannot be effectively reduced, and achieve the effects of reducing the risk of microbial growth, improving stability and simplifying the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The present embodiment provides a milk processing method for improving the stability of ultra-high temperature sterilized milk, which specifically includes the following steps:

[0054] (1) Raw milk inspection;

[0055] (2) Milk collection: the operating temperature is 1-6°C;

[0056] (3) Filtration: use a 30-mesh double filter;

[0057] (4) Sterilization separation and cream backfilling: use a sterilization separator (Tetra Pak sterilization separator) to operate, the centrifugal speed of the sterilization separator is 5500r / min, and the slag discharge frequency is 20min / time; the cream is backfilled The operation is performed at the time of sterilization separation (ie, backfilling while separating);

[0058] (5) Standardization: adopt the concentration method of membrane filtration to concentrate and separate the milk obtained in step (4);

[0059] (6) Storage: the storage temperature is 1-8℃;

[0060] (7) Ultra-high temperature sterilization: the temperature is ...

Embodiment 2

[0066] In this example, the sterilizing separator and the inspection index used in the milk processing method of Example 1 are specifically described as follows.

[0067] 1. Sterilization separator

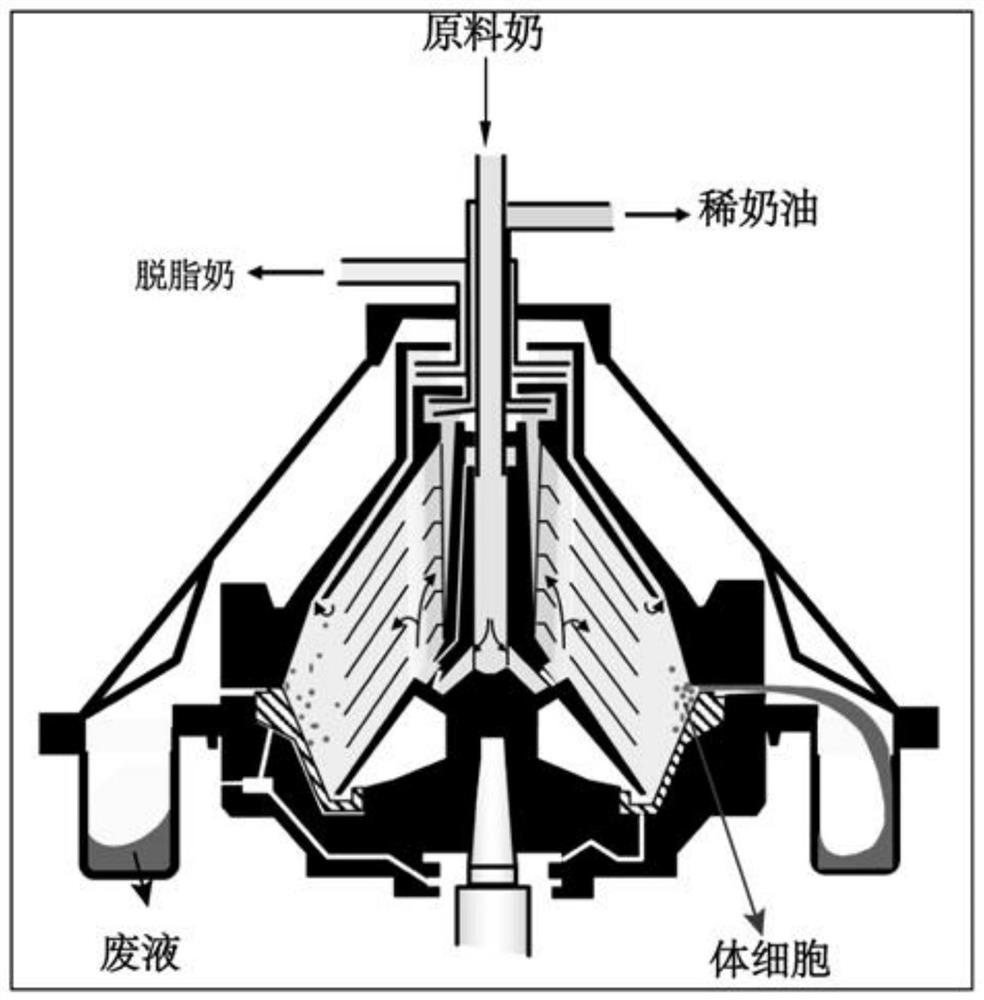

[0068] The basic principle of the sterilizing separator used in this embodiment is that milk is fed from the inlet by gravity, while the cream and skim milk are discharged under normal pressure, and then mixed in the pipeline to control a certain amount to achieve standardization. Waste fluid containing mammary gland infected somatic cells is discharged from the slag outlet (see figure 1 ).

[0069] 2. Inspection indicators

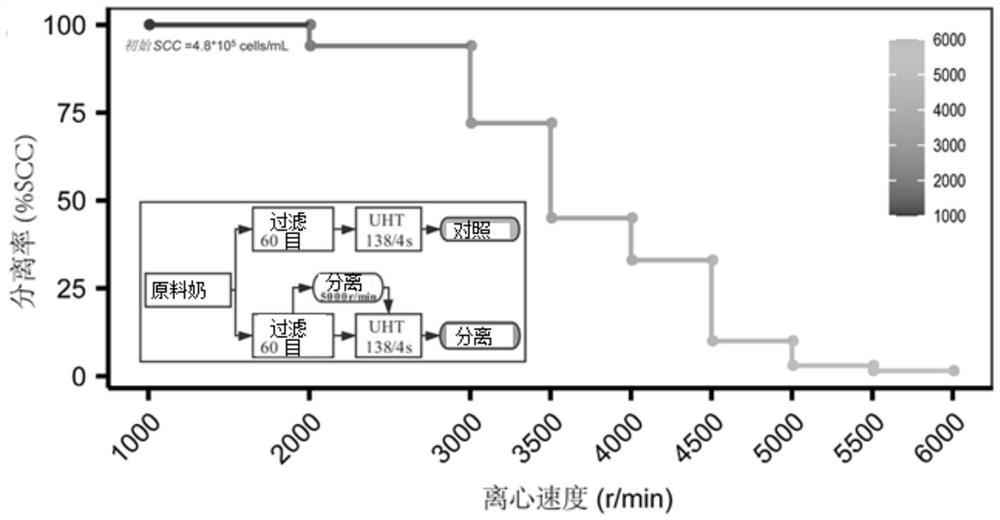

[0070] (1) Removal rate of mammary gland infected somatic cells: In order to maximize the removal rate of mammary gland infected somatic cells, the present invention carried out a centrifugal speed optimization experiment at the beginning of the design (see figure 2 ), the initial content of mammary gland infected somatic cells is 4.8×10 5 cells / mL, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com