Flue dust remover

A technology of dust collector and flue, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, use of liquid separation agent, etc. It can solve the problems of poor dust removal effect, increased labor and equipment costs, and large investment costs. Simple, low maintenance cost, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

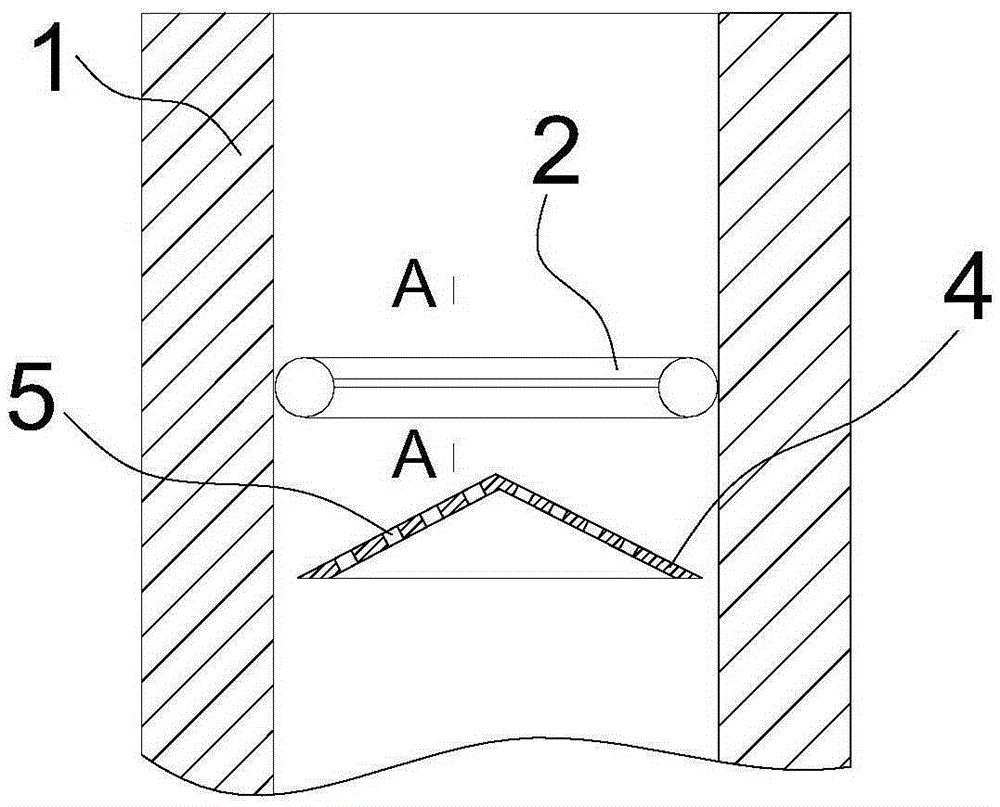

[0017] The specific working process of the flue dust collector of the present invention will be described in detail below in conjunction with the accompanying drawings.

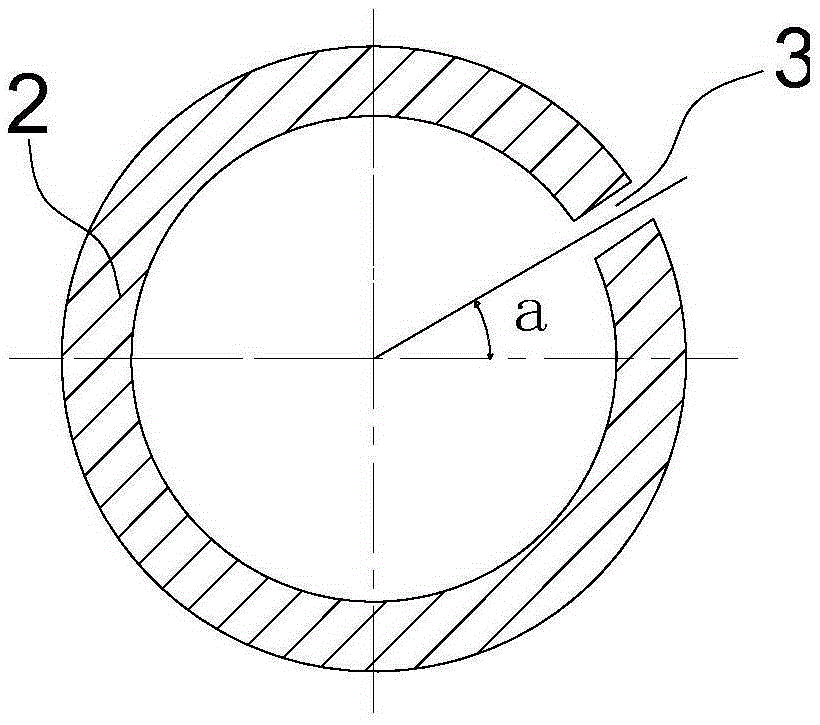

[0018] In the flue 1, an annular spray pipe 2 is installed. On the above-mentioned spray pipe 2, an annular spray groove 3 is opened toward the center. When the water in the spray pipe 2 passes through the pressure from the spray groove 3 After being sprayed out, a water curtain with larger water droplets is formed in the flue 1. When the flue gas containing particulate matter passes through the above-mentioned water curtain from bottom to top, the particulate matter is blocked by the water curtain and will increase in weight due to water content, so it will fall and will not be discharged upward with the flue gas to achieve the effect of dust removal.

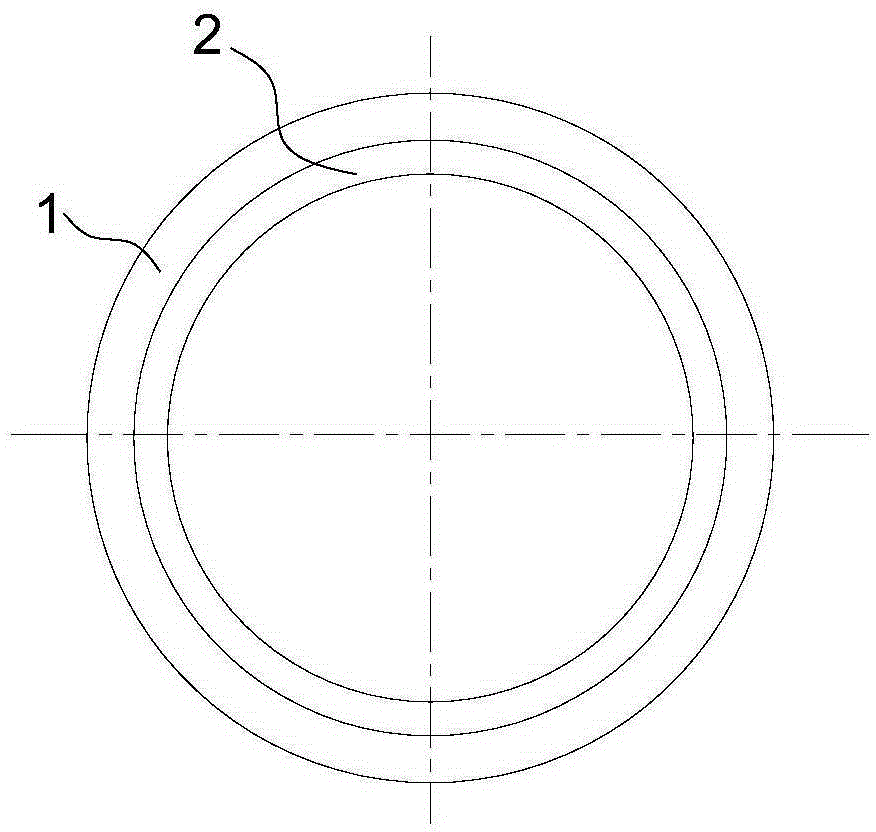

[0019] In order to make the water curtain evenly arranged in the cross section of the flue 1, the diameter of the spray pipe 2 is adapted to the inner diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com