Processing method of clamshell type thin-walled part

A technology of thin-walled parts and processing methods, which is applied in the processing field of clamshell thin-walled parts, can solve the problems of parts such as local size out-of-tolerance, overall bending, and poor shape, so as to improve processing accuracy and reduce the impact of dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

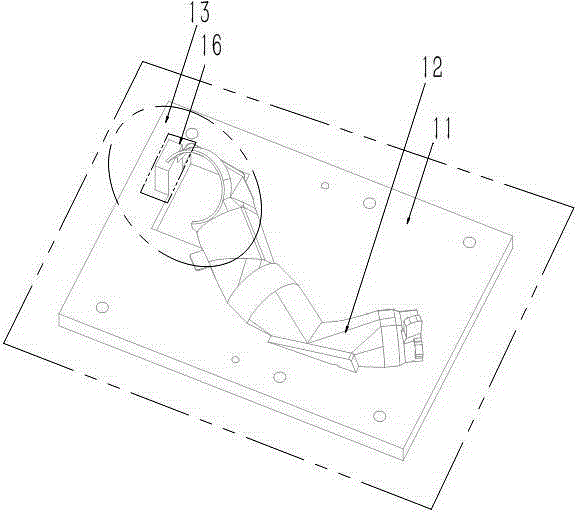

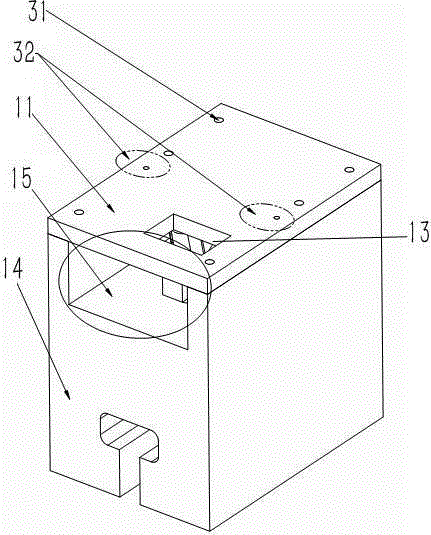

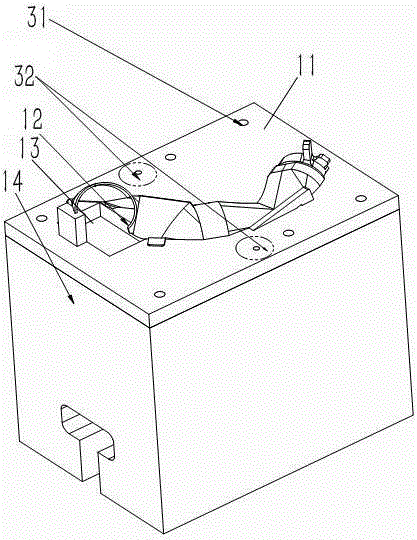

[0024] Embodiment of the processing method of clamshell-type thin-walled parts in the present invention: the clamshell-type thin-walled parts are formed by buckling the upper and lower clamshells. In this embodiment, the upper and lower clamshells are formed by the same process. The process consists of the following steps:

[0025] 1) According to the structural characteristics of clamshell thin-walled special-shaped parts, select the appropriate blank material as the base material, and formulate the process flow;

[0026] 2) Milling the square benchmark for the base material;

[0027] 3) Clamping in a vise, after milling out the square of the base material, the first CNC milling is performed on the base material, the first CNC milling is rough machining, and the inner concave surface of the part is milled out through fixed axis and variable axis programming methods And the convex surface, and leave a 1mm margin on the process handle, and mill out the clamping and positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com