Boring cutter with through groove for machining conduit hole

A technology of conduit holes and through grooves, which is applied in metal processing equipment, tools for lathes, manufacturing tools, etc., can solve the problems of low service life of cemented carbide materials, low machining accuracy and cutting speed, and insufficient strength of polycrystalline diamond. problems, to achieve the effect of good thermal conductivity and wear resistance, enhanced stability, and conducive to high-speed and high-precision processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

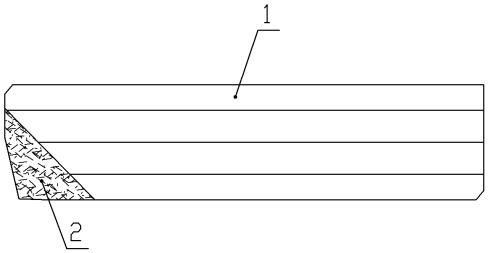

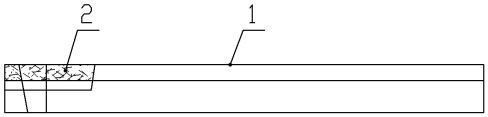

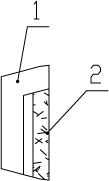

[0015] like Figure 4 ~ Figure 6 As shown, the through-groove boring tool for processing conduit holes of the present invention includes a cutter body 1, the upper surface of the cutter body 1 is provided with a cutting part 2 that fully covers the upper surface of the cutter body 1, and the cutter body 1 and the cutting part 2 are integrated by welding In this way, the joint surface between the cutting part 2 and the cutter body 1 is increased, the strength of the cutting part 2 is increased, and the stability is enhanced; the two ends of the cutting part 2 are respectively provided with a cutting edge 4 and a cutting edge 5, so that the front and rear of the boring tool The cutting edge 4 and the cutting edge 5 can be exchanged for use, which greatly prolongs the service life of the present invention. The cutting part 2 is made of polycrystalline diamond (PCD), which can achieve high machining accuracy in high-speed cutting, and the cutting part 2 made of PCD can also proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com