A method for manufacturing cold-drawn special steel round steel without decarburization layer on the surface

A manufacturing method and decarburization layer technology, which can be used in the manufacture of tools, machine tools designed for grinding the rotating surface of workpieces, metal material coating processes, etc. To avoid corrosion, increase product dimensional accuracy and product qualification rate, and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

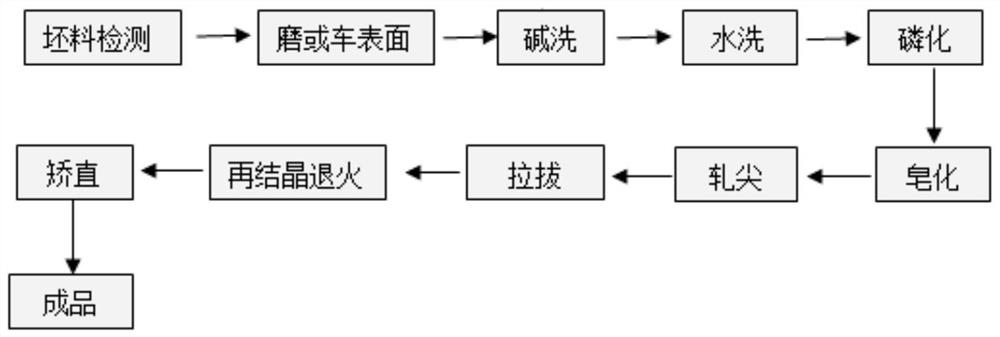

Method used

Image

Examples

Embodiment 1

[0042] Sampling and testing the internal quality of the billet steel (model: GCr15) before cold drawing according to the requirements, its specifications meet the requirements of GB / T18254-2016, and the hardness and the surface decarburization layer are tested. Unqualified special steel round steel billets;

[0043] The testing method of GB / T224 is used to measure the depth of the full decarburized layer of the special steel billet with qualified product quality and hardness, and the decarburized layer on the surface is gradually removed by a coreless grinder or a lathe in one pass or multiple passes, and finally the decarburized layer is completely removed. Carbon layer, and the surface roughness of the steel billet is Ra≤6.3um;

[0044]Put the steel billet after removing the decarburized layer into the alkaline water tank with pH of 12 and temperature of 60℃. powder to ensure subsequent phosphating and saponification treatment;

[0045] Put the alkali-washed steel billet i...

Embodiment 2

[0051] Sampling and testing the internal quality of the billet steel (model: GCr15) before cold drawing according to the requirements, its specifications meet the requirements of GB / T18254-2016, and the hardness and the surface decarburization layer are tested. Unqualified special steel round steel billets;

[0052] The detection method of GB / T224 is used to measure the depth of the full decarburization layer of the special steel billet, and the decarburized layer on the surface is gradually removed by a coreless grinder or a lathe in one pass or multiple passes, and finally the decarburized layer is completely removed, and the steel billet is completely removed. The surface roughness is Ra≤6.3um;

[0053] Put the steel billet after removing the decarburized layer into an alkaline water tank with pH of 11 and a temperature of 70°C. The steel billet should be completely immersed in the alkaline water, and the steel billet should be turned over from time to time to completely re...

Embodiment 3

[0060] Sampling and testing the internal quality of the billet steel (model: GCr15) before cold drawing according to the requirements, its specifications meet the requirements of GB / T18254-2016, and the hardness and the surface decarburization layer are tested. Unqualified special steel round steel billets;

[0061] The detection method of GB / T224 is used to measure the depth of the full decarburization layer of the special steel billet, and the decarburized layer on the surface is gradually removed by a coreless grinder or a lathe in one pass or multiple passes, and finally the decarburized layer is completely removed, and the steel billet is completely removed. The surface roughness is below Ra6.3um;

[0062] Put the steel billet after removing the decarburized layer into an alkaline water tank with pH of 10 and a temperature of 90°C. The steel billet should be completely immersed in the alkaline water, and the steel billet should be turned over from time to time to complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com