Adjustment method for fine adjustment of resistance value of thin film resistor, and thin film resistor

A thin film resistor, resistance adjustment technology, applied in the direction of fine-tuning resistors, resistance film/resistance coating is tapered, non-adjustable metal resistors, etc., can solve the problem of heavy workload, etching accuracy, laser equipment accuracy limitations, Design value deviation and other problems, to achieve the effect of improving efficiency, avoiding the influence of resistor dimensional accuracy and equipment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that in the case of no conflict, the following embodiments and the features in the embodiments can be combined with each other.

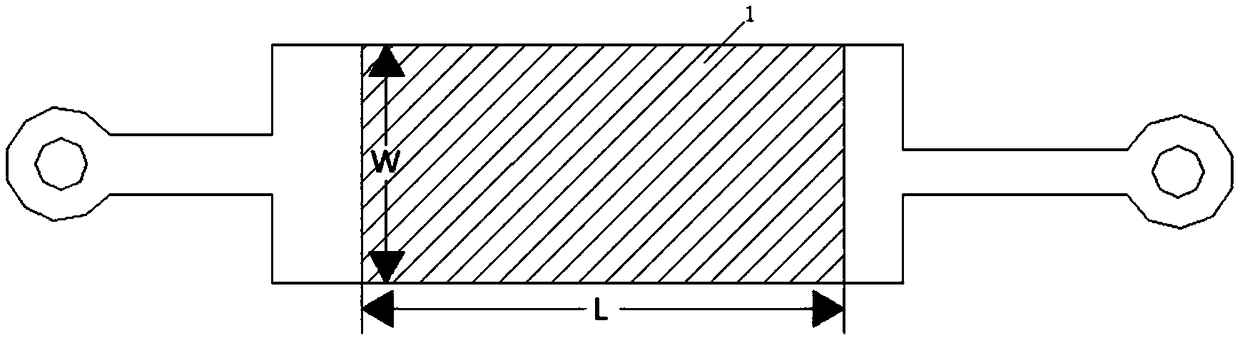

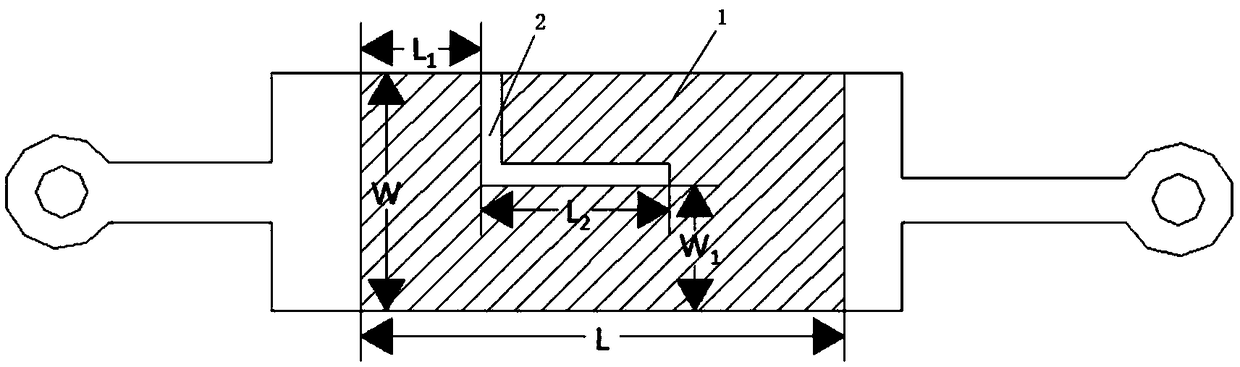

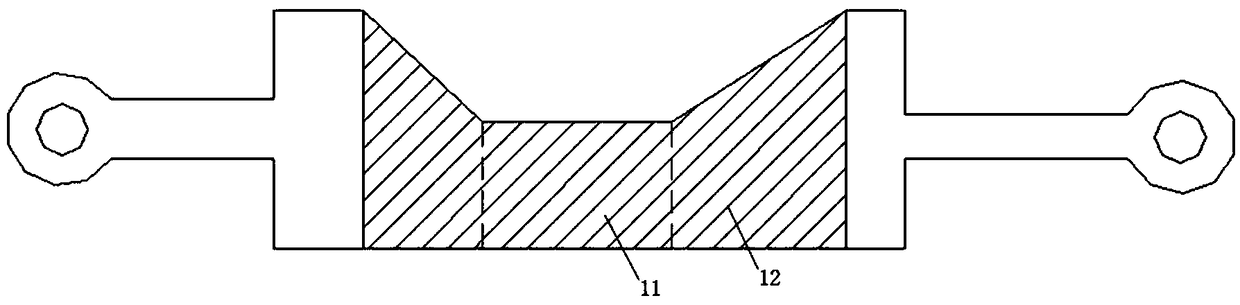

[0045] An adjustment method for fine-tuning the resistance value of a thin-film resistor, said method comprising setting several resistance adjustment holes, light spots or plaques inside the thin-film resistor according to the resistance value to be adjusted, and the thin-film resistance after setting the resistance adjustment holes or spots is Resistor after resistance adjustment. The manner of setting several resistance adjustment holes or spots includes single or double resistance adjustment holes, light spots, erosion spots, or matrix type resistance adjustment holes, light spots, and erosion spots.

[0046] Among them, the number and diameter of resistance adjustment holes, light spots or plaques are obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com