Grinding machine tool for cutting saw teeth of metal circular saw blade and using method for grinding machine tool

A circular saw blade and saw blade technology are applied in metal sawing equipment, tool dressing of sawing machine devices, metal processing equipment, etc., to avoid tooth burning, reduce transmission devices, and reduce tooth root arc phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

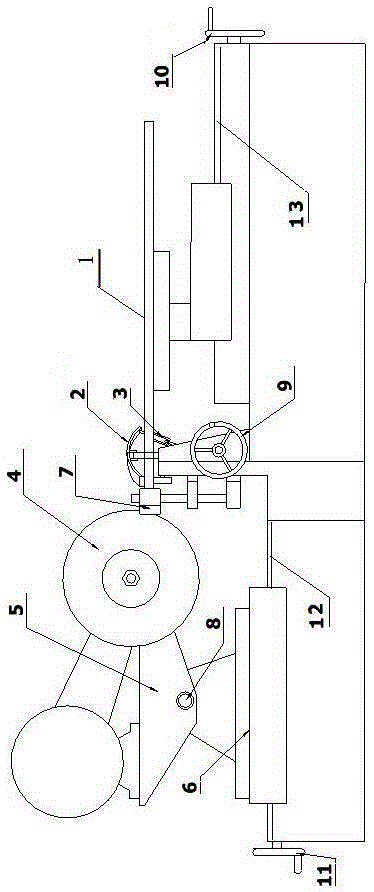

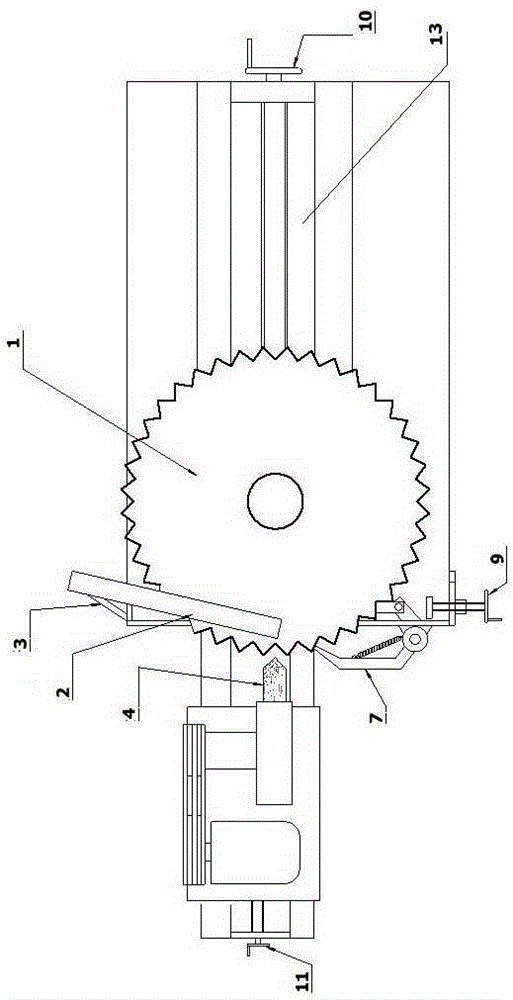

[0029] Specific implementation methods: such as figure 1 As shown, a grinding machine tool for cutting metal circular saw blades includes a base of the machine tool, on which a grinding head 5 and a saw blade grinding workbench are arranged, and a rotating circle for horizontally installing the saw blade 1 is arranged on the workbench. disc, and is equipped with a saw blade clamping device; the grinding head 5 is connected to the base through the grinding head base 6, the grinding head 5 is provided with a motor-driven grinding wheel 4, and the connection between the working table and the grinding wheel 4 is provided with a saw blade dial moving device. The base of the grinding machine tool is provided with a grinding head adjustment mechanism and a saw blade adjustment mechanism; the grinding head adjustment mechanism includes a connecting chute 12 between the grinding head base 6 and the base and a rotating shaft 8 on the grinding head base 6 . The chute is controlled and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com