Pneumatic control system and method for square ball valve automatic assembly workbench

A pneumatic control system and control system technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low work efficiency and high labor intensity, reduce labor intensity, simplify assembly process, ensure stability and unifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

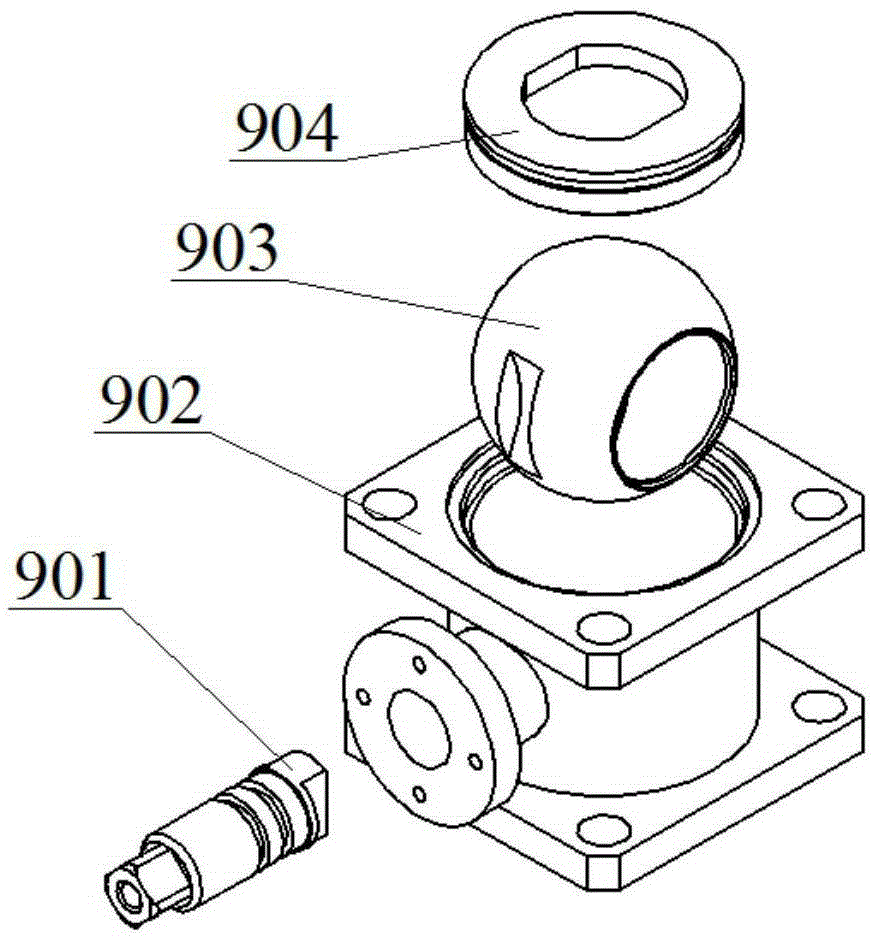

[0025] like figure 1 As shown, the square ball valve 9 for assembly includes a knob 901 , a valve body 902 , a valve core 903 and a valve cover 904 .

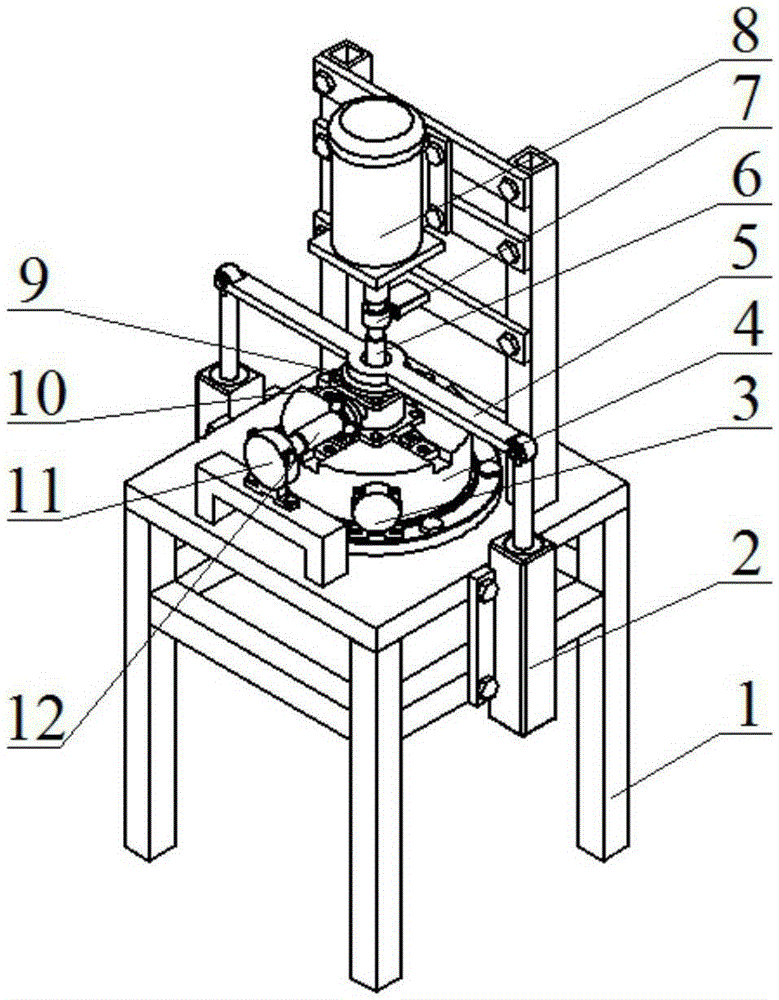

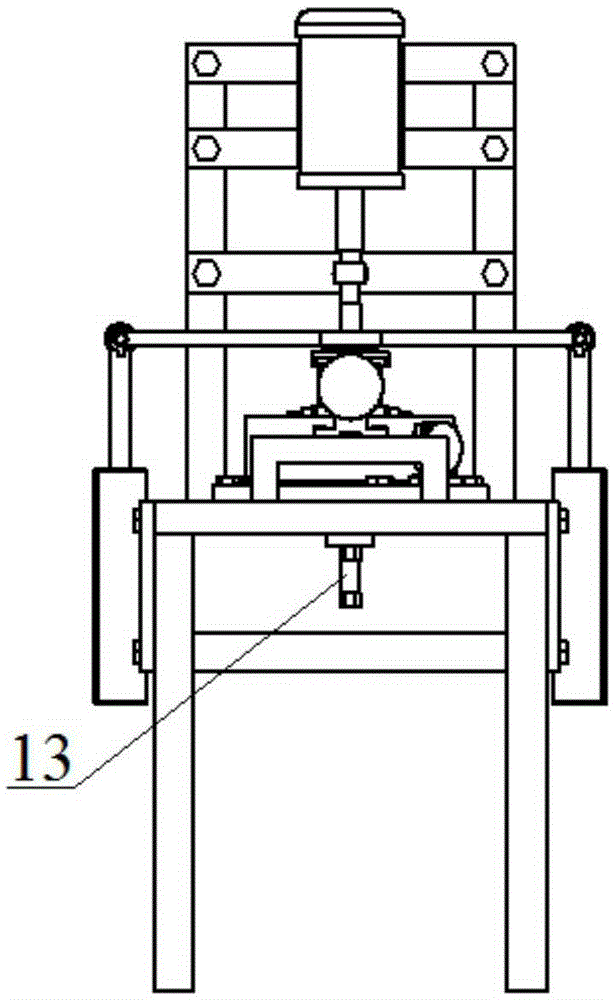

[0026] like Figures 2 to 3 As shown, the mechanical device of the square ball valve automatic assembly system of the present invention includes a frame 1, a cylinder 2, an air motor 3, a four-jaw chuck 4, a cylinder pressure plate 5, a main drive connector 6, a torque sensor 7, a motor 8, Rubber pad 10, air motor two 11, transmission sleeve 12 and pneumatic check valve 13.

[0027] like Figure 4 As shown, the pneumatic control system and method of the square ball valve automatic assembly workbench of the present invention, the pneumatic control system includes an air source 19, a controller 14, a valve body 902 clamping control system, a valve cover 904 tightening control system, a valve core 903 inflation control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com