Spraying alive-keeping transport vehicle for abalone

A transport vehicle and abalone technology, which is applied in the field of abalone spraying and keeping alive transport vehicles, can solve the problems of water circulation system failure, leakage of circulating water, change of vehicle center of gravity, etc., and achieve the effects of avoiding failure, spraying stability, and slowing down the front and rear shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

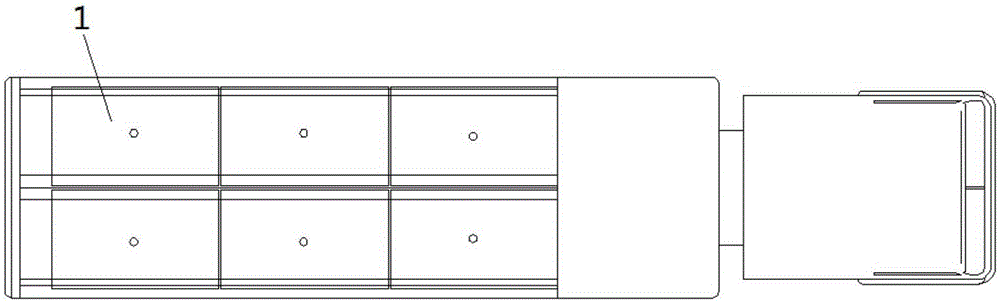

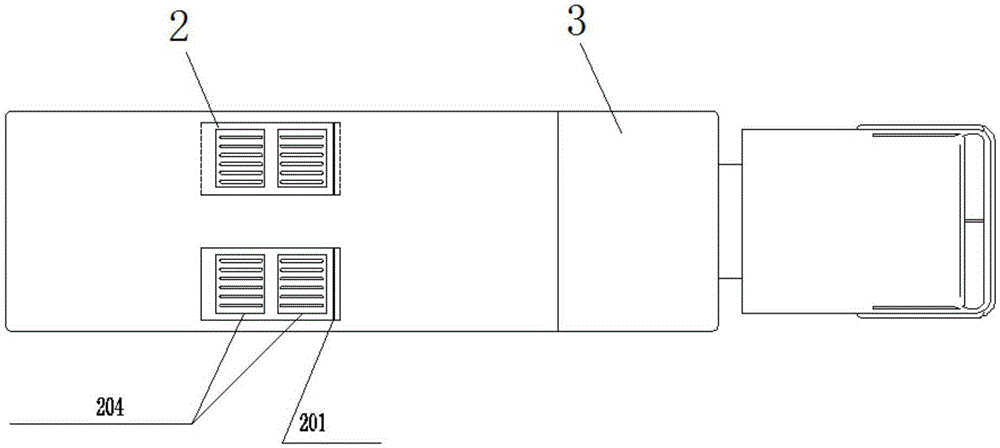

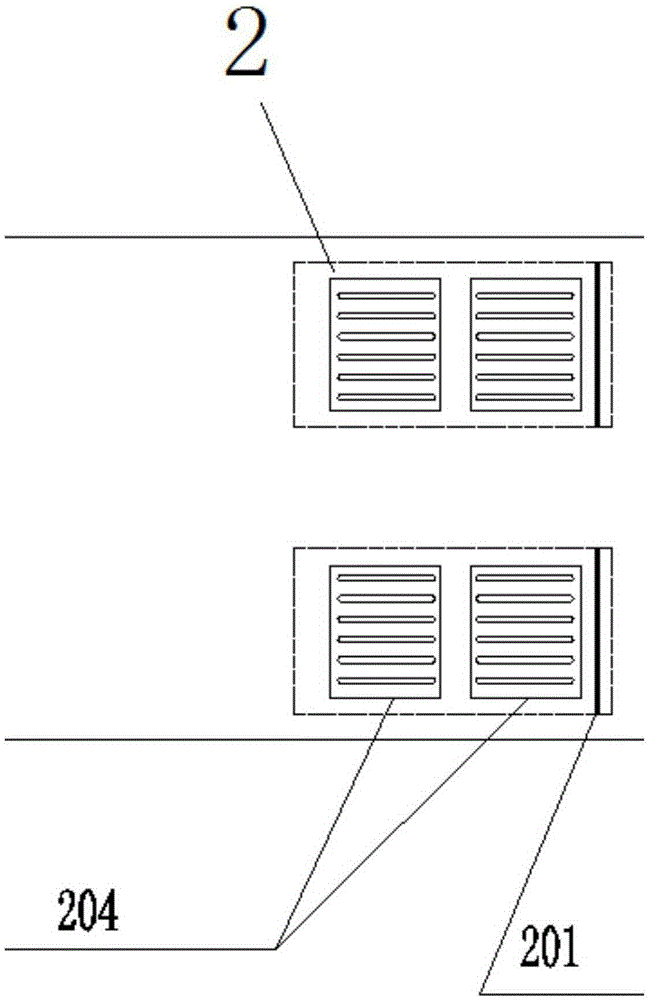

[0036] see figure 2 , 10 , 11. Firstly, the specific description of the water storage tank is as follows:

[0037]The box is divided into two independent areas, the impurity isolation area and the purification area, separated by a partition 311 in the middle, the upper and lower parts of the partition 311 are stainless steel plates with a height of 0.5 meters, and the middle part is a stainless steel mesh plate (mesh diameter<2mm ) cover, allowing water to pass through, while impurities are isolated and deposited in the isolation area. During the circulation, it can remove the submerged impurities such as aquatic plants, broken shells and attachments in the fresh and live abalone during the preservation process, as well as the floating impurities such as abalone's own secretions, excreta and protein foam produced by long-term circulation. ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com