Method for preparing powder material

A powder material and feed liquid technology, applied in the field of powder material preparation, can solve the problems of wide particle size distribution, poor product batch stability, uneven crystal particle size of finished powder, etc., to achieve effective regulation and improve batch stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] As shown in the figure, the present invention adopts the following steps:

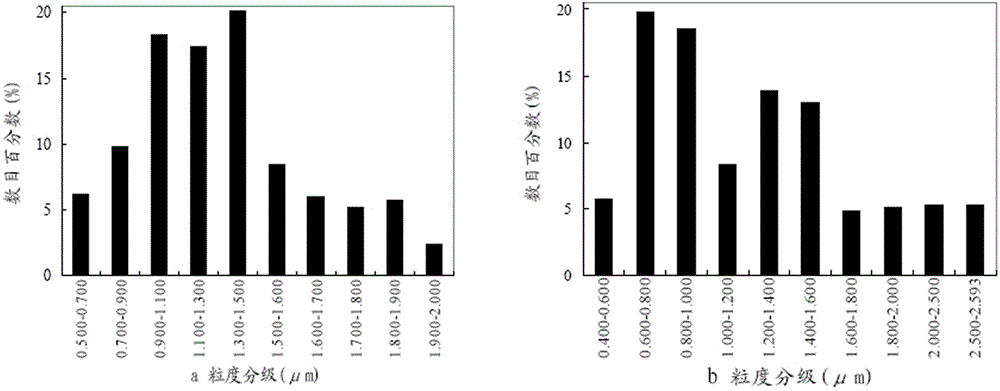

[0016] 1) Prepare 0.5mol / LNaCO3 solution and 0.5mol / LSrCl2 solution, use pipeline precipitation reactor method and conventional forward precipitation method to prepare strontium carbonate respectively, and measure and compare the particle size distribution and shape of the generated strontium carbonate.

[0017] 2) Using the pipeline precipitation reactor method, the NaCO3 solution and the SrCl2 solution respectively enter the pipeline through the constant pressure high level tank from the feed port, and under the high-speed rotation of the impeller, the two feed solutions are mixed and reacted instantly in the pipeline to form SrCO3 precipitation , and discharged into the stirring and heating beaker from the open lower outlet, stirring for 30min, the reaction temperature is 50-60°C.

[0018] 3) For forward precipitation, put the SrCl2 solution into a stirred and heated beaker first, add NaCO3 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com