Silicide/oxide composite negative electrode material with lithium silicate interface layer and preparation method

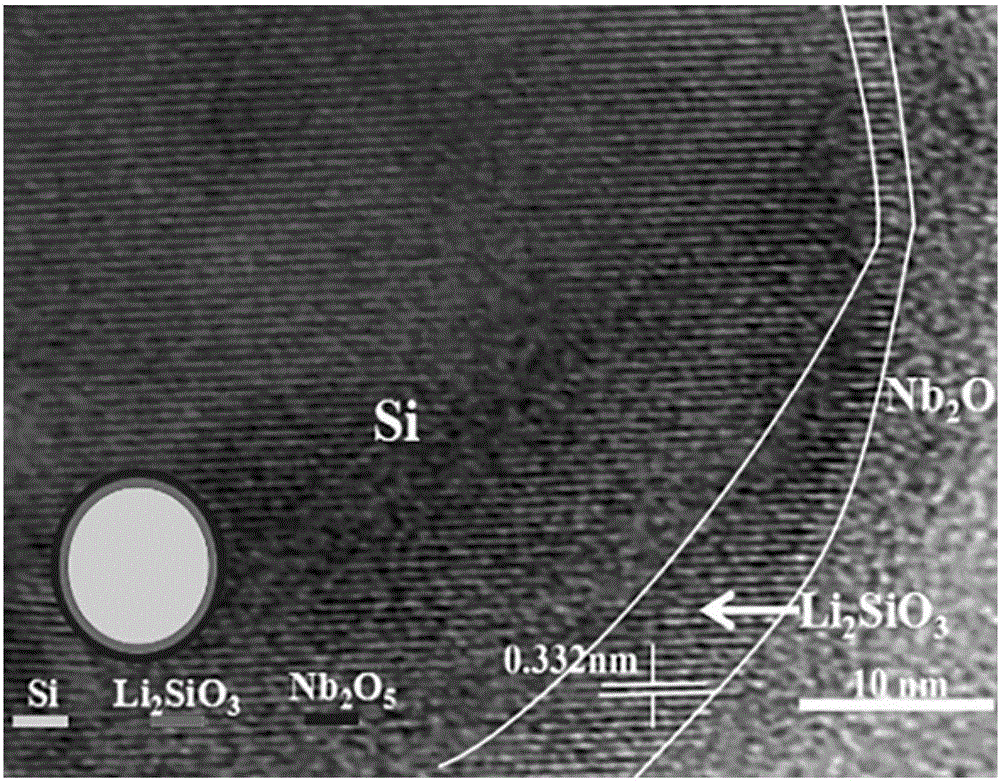

A negative electrode material and oxide technology, which is applied in the field of silicon/oxide composite materials and its preparation, can solve the problems of silicon surface instability, volume expansion mismatch, separation of silicon active centers and matrix materials, etc., to promote efficient transmission , the effect of good ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Mix absolute ethanol (analytical pure) and deionized water at a volume ratio of 1:1 to obtain an ethanol-water mixed solution for later use;

[0045] (2) Dissolve 0.27g of niobium chloride in 40ml of absolute ethanol solution for later use;

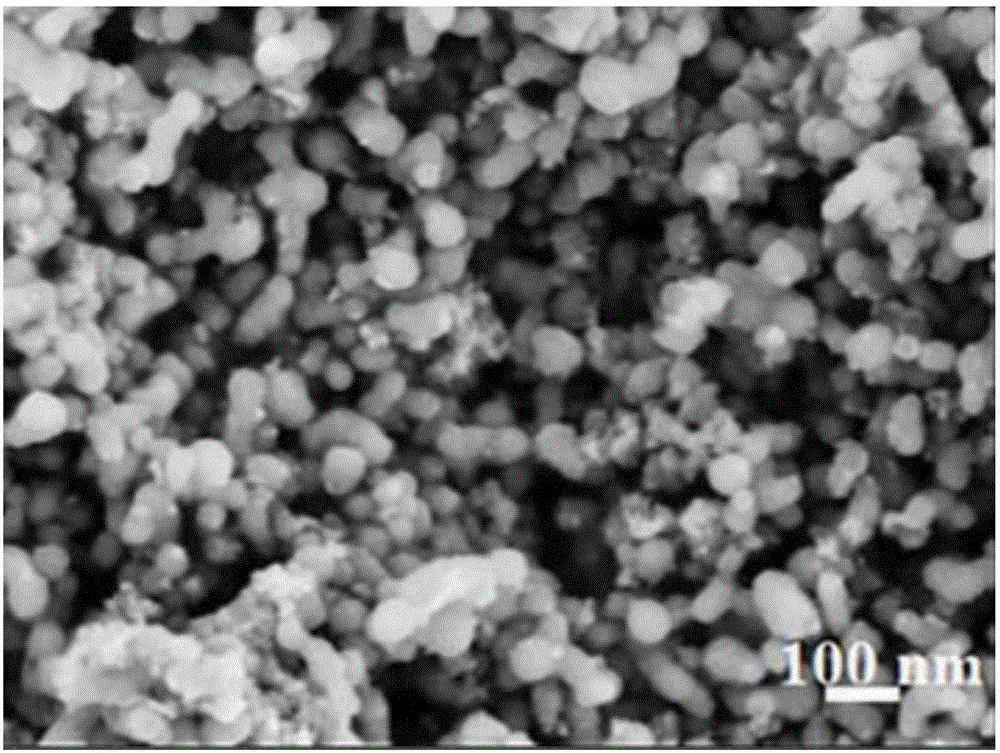

[0046] (3) Put 0.11g of nano-silicon powder (average particle size is 40nm) into the niobium chloride / ethanol solution, and ultrasonically vibrate for 30min to make a silicon powder-niobium chloride / ethanol solution;

[0047] (4) Prepare lithium hydroxide into a 0.02mol / L lithium hydroxide / ethanol-water mixed solution (the volume ratio of ethanol:water is 1:1);

[0048] (5) Take 250ml of lithium hydroxide / ethanol-water mixed solution (20mmol / L), and add it dropwise to the silicon powder-niobium chloride / ethanol solution. : 1) washing 3 times until the filtrate is neutral, and drying in vacuum at 70° C. for 8 hours;

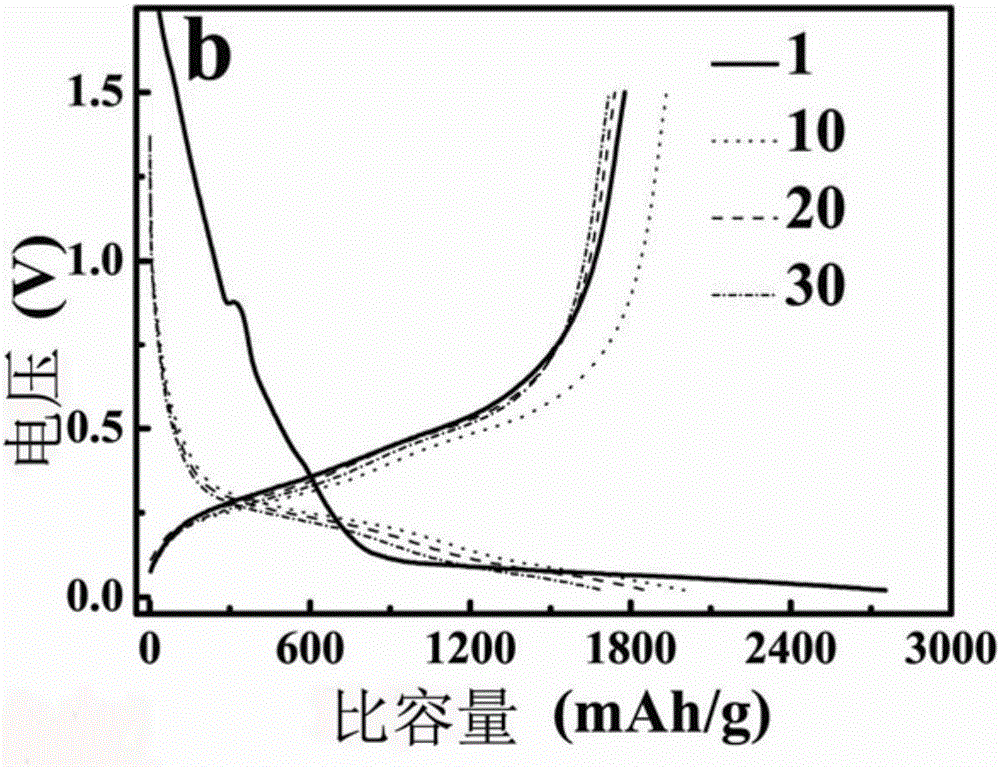

[0049] ⑹ Place the dried sample in a tube furnace, raise the temperature from room temperature to 600 °C at a ...

Embodiment 2

[0054] (1) Mix ethylene glycol (analytical pure) and deionized water at a volume ratio of 2:1 to obtain an ethylene glycol-water mixed solution for later use;

[0055] (2) Dissolve 0.27g niobium chloride in 40ml ethylene glycol solution for later use;

[0056] (3) Put 0.13g of nano-silicon powder (40nm) into the niobium chloride / ethylene glycol solution and oscillate ultrasonically for 30 minutes to make a silicon powder-niobium chloride / ethylene glycol solution;

[0057] (4) Use lithium hydroxide to prepare a 20mmol / L lithium hydroxide / ethylene glycol-mixed solution (the volume ratio of ethanol:water is 2:1);

[0058] (5) Take 250ml of lithium hydroxide / ethylene glycol-mixed solution (20mmol / L), and add it dropwise to the silicon powder-niobium chloride / ethylene glycol solution. After the reaction is completed, precipitate and filter, and use the ethanol-water mixed solution (2 : 1) Washing twice until the filtrate is neutral, and drying in vacuum at 60° C. for 10 hours;

...

Embodiment 3

[0062] ⑴ Mix ethanol (analytical pure) and deionized water at a volume ratio of 1:1 to obtain an ethanol-water mixed solution for later use;

[0063] (2) Dissolve 0.27g niobium chloride and 0.34g tetrabutyl titanate in 40ml ethanol solution for later use;

[0064] (3) Put 0.15g of nano-silicon powder (40nm) into niobium chloride-tetrabutyl titanate / ethanol solution, and ultrasonically oscillate for 30min to make silicon powder-niobium chloride-tetrabutyl titanate / ethanol solution;

[0065] (4) Prepare lithium hydroxide with 20mmol / L lithium hydroxide / ethanol-mixed solution (the volume ratio of ethanol:water is 1:1);

[0066] (5) Take 500ml of lithium hydroxide / ethanol-mixed solution (20mmol / L), add it dropwise to the silicon powder-niobium chloride / ethanol solution, after the reaction is completed, precipitate and filter, and wash with ethanol-water mixed solution (1:1) 3 times until the filtrate is neutral, vacuum dry at 70°C for 8 hours;

[0067] ⑹ Place the dried sample i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com