Method for controlling homogeneity of structure properties of high-strength and high-plasticity TB6 titanium alloy wires

A titanium alloy wire, microstructure and performance technology, applied in the field of high-strength and high-plasticity TB6 titanium alloy wire microstructure and performance uniformity control, can solve the problems of alloy plasticity reduced to about zero, alloy plasticity reduction, high ω phase strength, etc., to improve cold High rolling deformation ability, high tensile strength, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

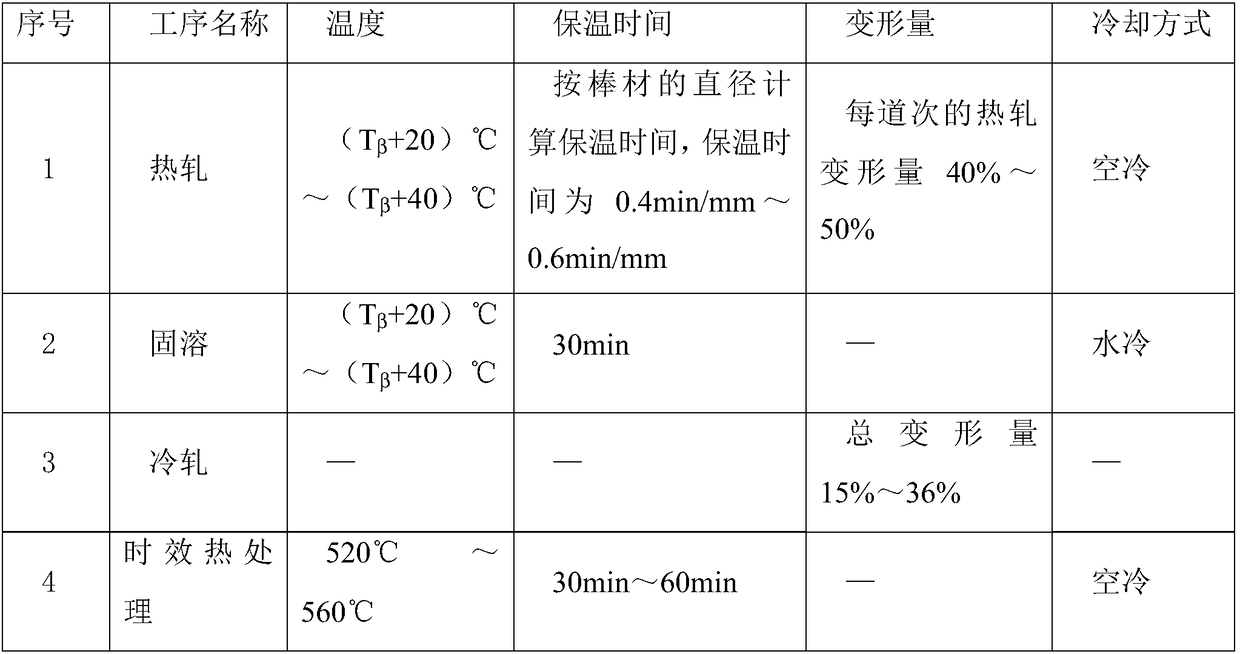

[0026] The specific preparation process steps and process parameters of TB6 titanium alloy wire are shown in Table 1.

[0027] Table 1 Process steps and process parameters for wire preparation

[0028]

Embodiment 1

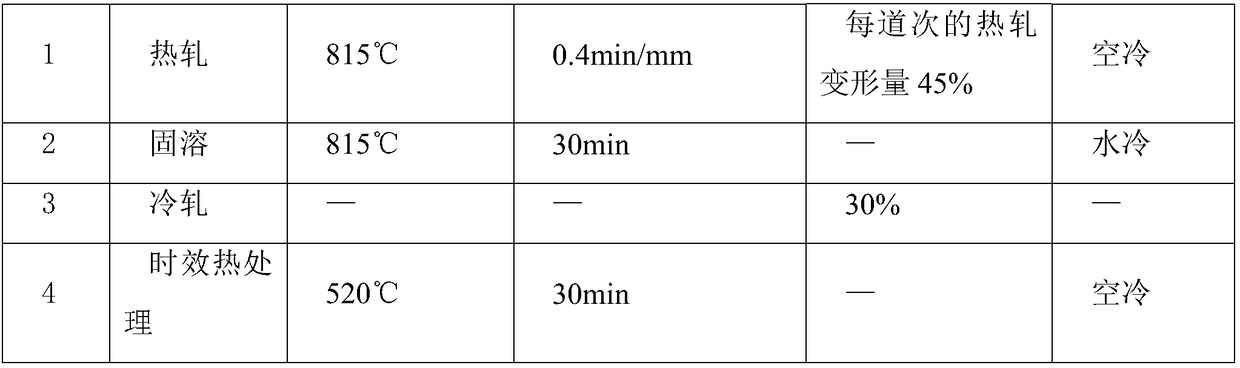

[0030] The specific process steps and process parameters of TB6 titanium alloy bar (Φ40mm×1200mm) are shown in Table 2, and the properties of the cold-rolled wire after aging are shown in Table 3.

[0031] Processing steps and process parameter (T of table 2 embodiment 1 β =795°C)

[0032]

[0033]

[0034] Tensile properties at room temperature after the wire material aging of table 3 embodiment 1

[0035] serial number

Embodiment 2

[0037] The specific process steps and process parameters of TB6 titanium alloy bar (Φ42mm×800mm) are shown in Table 4, and the properties of the cold-rolled wire after aging are shown in Table 5.

[0038] Processing steps and processing parameter (T of table 4 embodiment 2 β =802°C)

[0039]

[0040] Tensile properties at room temperature after the wire aging of Table 5 Example 2

[0041] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com