A high-strength aluminum-magnesium alloy welding wire and its processing technology

An aluminum-magnesium alloy, high-strength technology, used in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of hindering the sedimentation of the protective agent, affecting the performance of the alloy, short service life, etc., to improve the protection effect and service life, The effect of increasing service life, improving strength and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] First prepare raw materials, weigh aluminum ingots, magnesium ingots, zinc ingots, aluminum-chromium master alloys, aluminum-manganese master alloys, aluminum-silicon master alloys, aluminum-titanium master alloys, aluminum-beryllium master alloys and rare earths in proportion, and set aside; weigh in proportion Calcium carbonate, magnesium chloride, sodium chloride, potassium chloride and additives are uniformly mixed to obtain a protective flux for subsequent use; graphene oxide, sodium sulfate and carbon are weighed in proportion for subsequent use;

[0053] Then take aluminum ingots, zinc ingots, aluminum-chromium master alloys, aluminum-titanium master alloys, aluminum-beryllium master alloys and rare earths, put them into the melting furnace, heat up to 760°C, stir and melt for 8 hours, then add 1 / 4 of the protective flux, and heat Melt and stir evenly to obtain material A; adjust the temperature to 750°C, add magnesium ingots to material A until it is completely m...

Embodiment 2

[0058] First prepare raw materials, weigh aluminum ingots, magnesium ingots, zinc ingots, aluminum-chromium master alloys, aluminum-manganese master alloys, aluminum-silicon master alloys, aluminum-titanium master alloys, aluminum-beryllium master alloys and rare earths in proportion, and set aside; weigh in proportion Calcium carbonate, magnesium chloride, sodium chloride, potassium chloride and additives are uniformly mixed to obtain a protective flux for subsequent use; graphene oxide, sodium sulfate and carbon are weighed in proportion for subsequent use;

[0059] Then take aluminum ingots, zinc ingots, aluminum-chromium master alloys, aluminum-titanium master alloys, aluminum-beryllium master alloys and rare earths, put them into the melting furnace, heat up to 780°C, stir and melt for 9 hours, then add 1 / 4 of the protective flux, and heat Melt and stir evenly to obtain material A; adjust the temperature to 755°C, add magnesium ingots to material A until it is completely m...

Embodiment 3

[0064] First prepare raw materials, weigh aluminum ingots, magnesium ingots, zinc ingots, aluminum-chromium master alloys, aluminum-manganese master alloys, aluminum-silicon master alloys, aluminum-titanium master alloys, aluminum-beryllium master alloys and rare earths in proportion, and set aside; weigh in proportion Calcium carbonate, magnesium chloride, sodium chloride, potassium chloride and additives are uniformly mixed to obtain a protective flux for subsequent use; graphene oxide, sodium sulfate and carbon are weighed in proportion for subsequent use;

[0065] Then take aluminum ingots, zinc ingots, aluminum-chromium master alloys, aluminum-titanium master alloys, aluminum-beryllium master alloys and rare earths, put them into the melting furnace, heat up to 800°C, stir and melt for 10 hours, then add 1 / 4 of the protective flux, and heat Melt and stir evenly to obtain material A; adjust the temperature to 760°C, add magnesium ingots to material A until it is completely ...

PUM

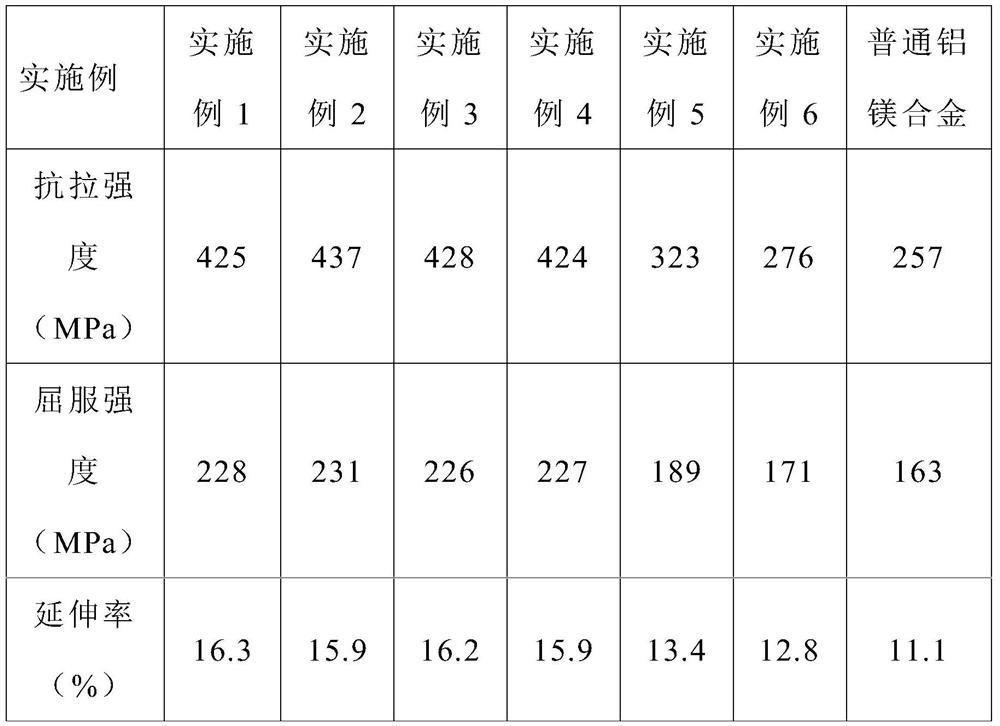

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com