Al-Cu-Sc-B heat-resistant aluminum alloy monofilament material and preparation method thereof

An al-cu-sc-b, aluminum alloy monofilament technology, applied in the field of electrical conductor materials, can solve the problems of increased line loss, waste of electric energy, poor overall performance, etc., and achieve the effect of improving conductivity and optimizing preparation process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

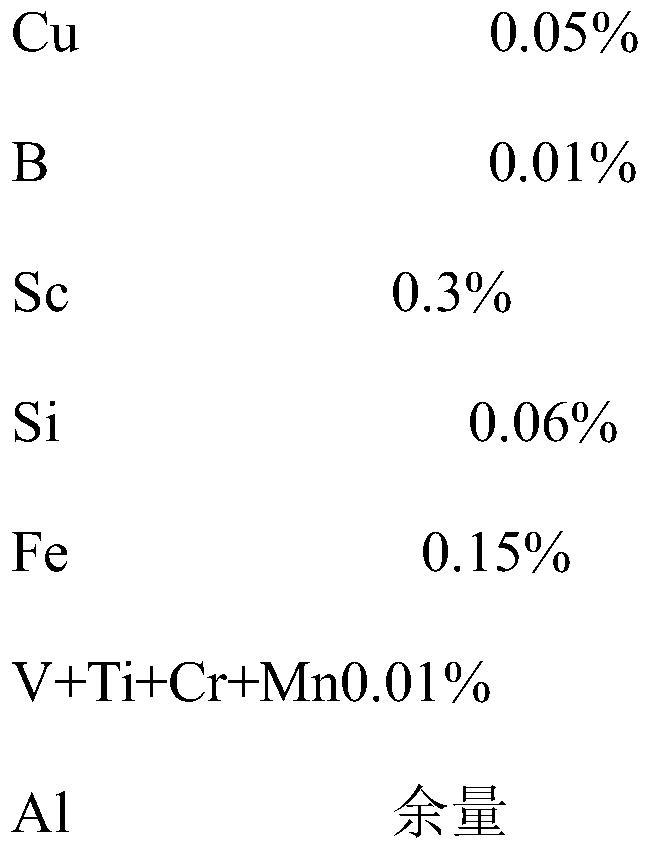

[0033] A kind of Al-Cu-Sc-B heat-resistant aluminum alloy monofilament material, composition and weight percentage thereof are:

[0034]

[0035] Pure aluminum ingots with a purity of 99.7% are added with Cu, B, and Sc alloying elements to make their final contents as shown above, and the alloying elements are added in the form of master alloys. After smelting, casting, and rolling at 500°C for 2 hours, a round aluminum rod was obtained, and after drawing, a Φ4mm aluminum alloy monofilament was obtained, and held at 190°C for 3 hours. The conductivity of the monofilament is 61.9%IACS (20°C), the tensile strength is 170MPa, the elongation is 2.1%, and the residual strength rate of 230°C for 1h is ≥93%, which meets the requirement of long-term operation temperature of 150°C.

Embodiment 2

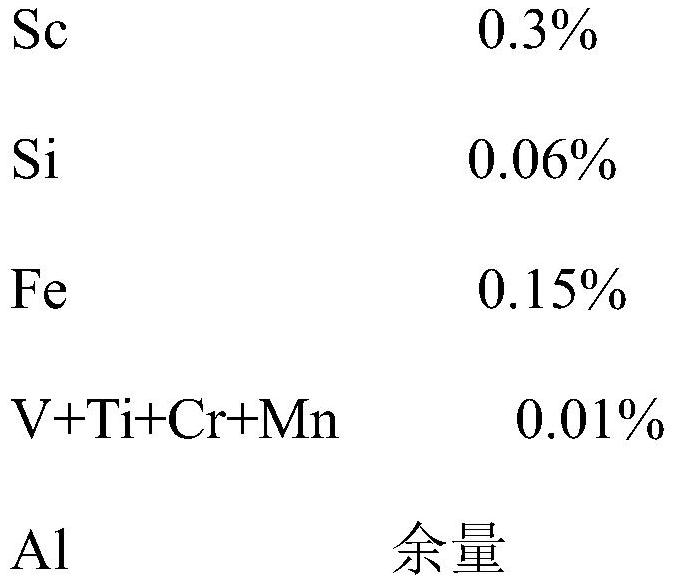

[0037] A kind of Al-Cu-Sc-B heat-resistant aluminum alloy monofilament material, composition and weight percentage thereof are:

[0038]

[0039]

[0040]Pure aluminum ingots with a purity of 99.7% are added with Cu, B, and Sc alloying elements to make their final contents as shown above, and the alloying elements are added in the form of master alloys. After smelting, casting, and rolling at 490°C for 3 hours, a round aluminum rod was obtained. After drawing, a Φ3.5mm aluminum alloy monofilament was obtained, and held at 180°C for 4 hours. The conductivity of the monofilament is 61.8%IACS (20°C), the tensile strength is 180MPa, the elongation is 2.0%, and the residual strength rate of 230°C for 1h is ≥94%, which meets the requirement of long-term operation temperature of 150°C.

Embodiment 3

[0042] A kind of Al-Cu-Sc-B heat-resistant aluminum alloy monofilament material, composition and weight percentage thereof are:

[0043]

[0044] Pure aluminum ingots with a purity of 99.7% are added with Cu, B, and Sc alloying elements to make their final contents as shown above, and the alloying elements are added in the form of master alloys. After smelting, casting, rolling at 460°C for 4 hours to obtain a round aluminum rod, and after drawing to obtain a Φ3.2mm aluminum alloy monofilament, hold at 160°C for 7 hours. The conductivity of the monofilament is 61.9%IACS (20°C), the tensile strength is 168MPa, the elongation is 2.2%, and the residual strength rate of 230°C for 1h is ≥92%, which meets the requirement of long-term operation temperature of 150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com