A preparation method for extracting soluble and insoluble dietary fiber from wild jujube dregs

A soluble dietary fiber and soluble technology, which is applied in the field of preparation of soluble and insoluble dietary fiber in extracting wild jujube dregs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

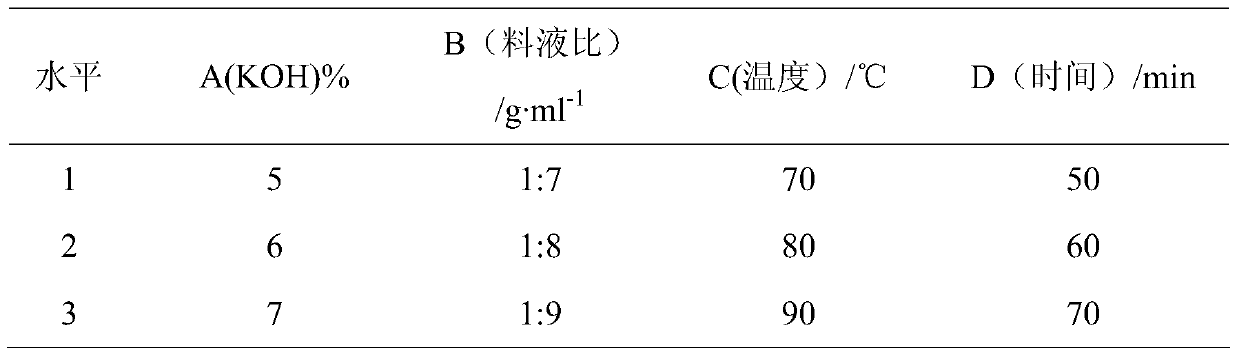

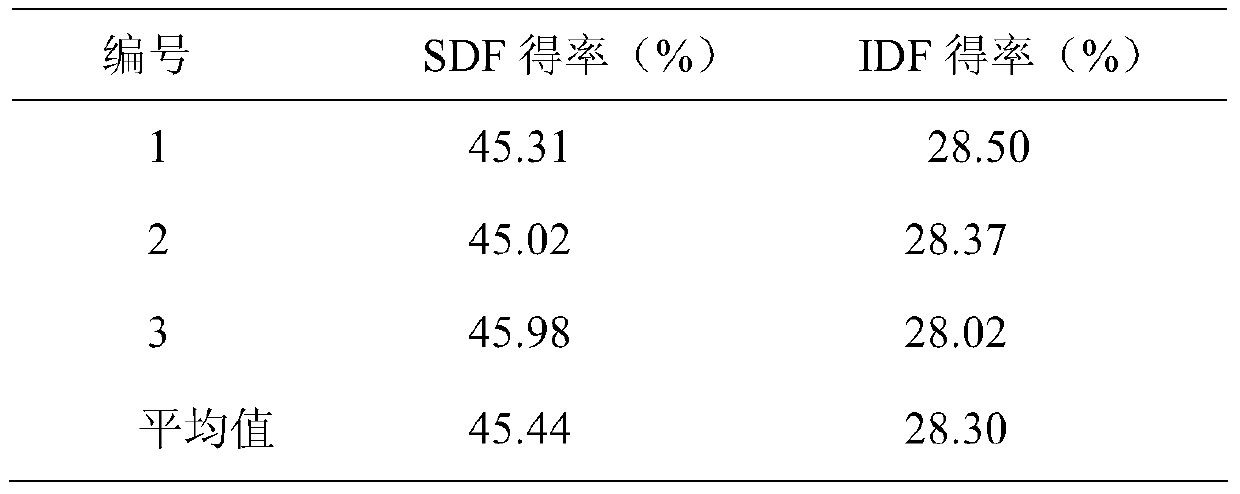

Embodiment 1

[0065] (1) Drying and pulverizing the degreasing, decolorizing, and extracting the jujube pulp slag to obtain the jujube pulp powder;

[0066] (2) The KOH solution with a mass concentration of 7% and the jujube fruit pulp powder obtained in step (1) are 8:1 according to the mass ratio, the alkali hydrolysis temperature is 90 ° C, and after the alkali hydrolysis time is 70 minutes, the filter residue and the filtrate are obtained by suction filtration;

[0067] (3) Take the filtrate in step (2) to adjust the pH to 7, concentrate, add 5 times the amount of 95% ethanol, and filter with suction to obtain a precipitate, which is the water-soluble dietary fiber of jujube pulp;

[0068] (4) Take the filter residue in step (2) and decolorize it with 5% hydrogen peroxide, adjust the pH to be 7, suction filter, wash the filter residue with water, wash with ethanol, and dry to obtain the jujube insoluble dietary fiber.

Embodiment 2

[0070] (1) Drying and pulverizing the degreasing, decolorizing, and extracting the jujube pulp slag to obtain the jujube pulp powder;

[0071] (2) The KOH solution with a mass concentration of 8% and the jujube fruit pulp powder obtained in step (1) are 9:1 according to the mass ratio, the alkali hydrolysis temperature is 70 ° C, and after the alkali hydrolysis time is 50 minutes, the filter residue and the filtrate are obtained by suction filtration;

[0072] (3) Take the filtrate in step (2) to adjust the pH to 7, concentrate, add 4 times the amount of 95% ethanol, and filter with suction to obtain a precipitate, which is the water-soluble dietary fiber of jujube pulp;

[0073] (4) Get the filter residue in step (2) and decolorize it with 6% hydrogen peroxide, adjust the pH to be 7, carry out suction filtration, wash the filter residue with water, wash with ethanol, and dry to obtain the jujube insoluble dietary fiber.

Embodiment 3

[0075] (1) Drying and pulverizing the degreasing, decolorizing, and extracting the jujube pulp slag to obtain the jujube pulp powder;

[0076] (2) the KOH solution with a mass concentration of 6% and the jujube fruit pulp powder obtained in step (1) are 7:1 according to the mass ratio, the alkali hydrolysis temperature is 80 ° C, and after the alkali hydrolysis time is 70 minutes, the filter residue and the filtrate are obtained by suction filtration;

[0077] (3) Take the filtrate in step (2) to adjust the pH to 7, concentrate, add 4 times the amount of 95% ethanol, and filter with suction to obtain a precipitate, which is the water-soluble dietary fiber of jujube pulp;

[0078] (4) Get the filter residue in step (2) and decolorize it with 4% hydrogen peroxide, adjust the pH to be 7, carry out suction filtration, wash the filter residue with water, wash with ethanol, and dry to obtain the jujube insoluble dietary fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com