Preparation method of lithium ion battery positive electrode material

A technology for lithium ion batteries and positive electrode materials is applied in the field of preparation of positive electrode materials for lithium ion secondary batteries, and can solve the problems affecting material processing performance and compaction density, potential safety hazards in transportation and storage, and easily exceeding the standard of magnetic impurities in synthetic products. , to achieve the effect of excellent water absorption and high temperature cycle performance, good consistency and short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for preparing a lithium-ion battery positive electrode material, the steps are as follows:

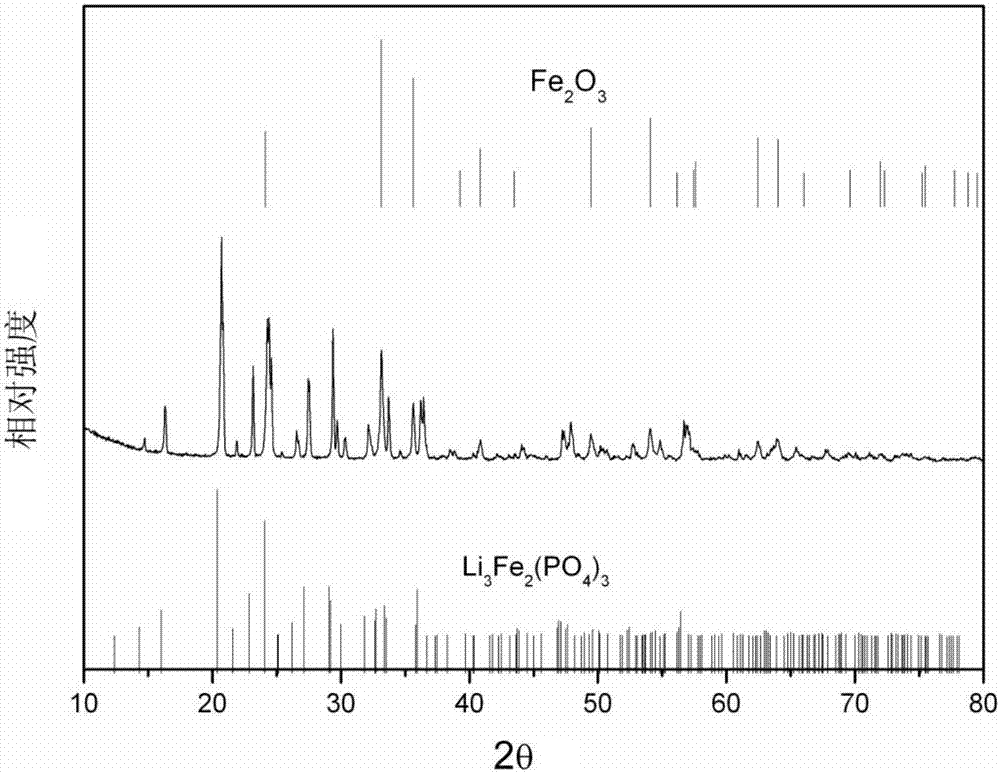

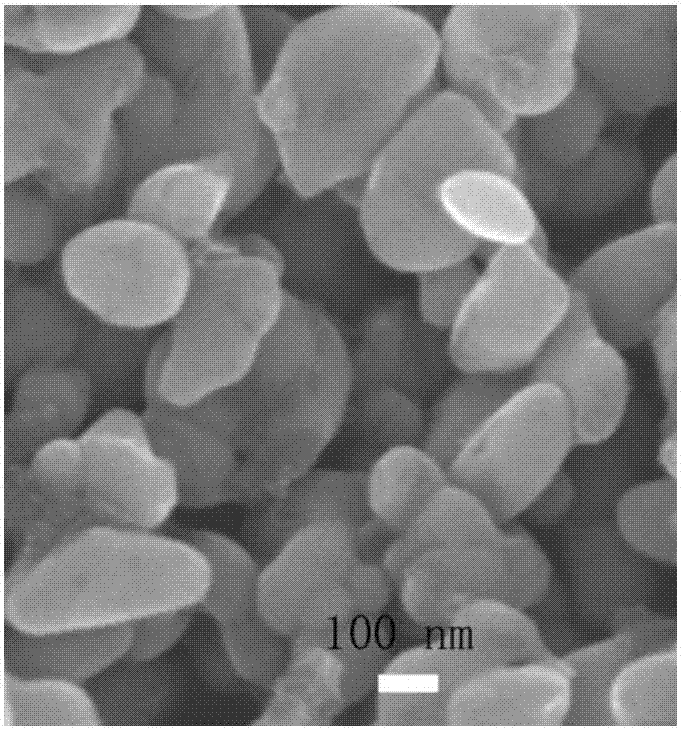

[0038] Will Li 2 CO 3 、FePO 4 2H 2 O was mixed in a molar ratio of 1:2. The mixed raw materials were put into a muffle furnace and pre-fired at 500°C for 5 hours to obtain a red powder, which was Li 3 Fe 2 (PO 4 ) 3 and Fe 2 o 3 mixture, its XRD such as figure 1 shown. After the temperature of the mixture dropped to room temperature, it was put into deionized water for grinding, the grinding rate was 1000r / min, and FePO was added in 0.5h 4 2H 2 O quality 10% glucose, continue to grind at the same rate for 0.5h, then continue to grind at a high rate (3000r / min) for 0.5h. After drying, in a nitrogen atmosphere, the second sintering was carried out at 600 ° C for 6 hours to obtain LFP / C, the morphology of which is as follows figure 2 .

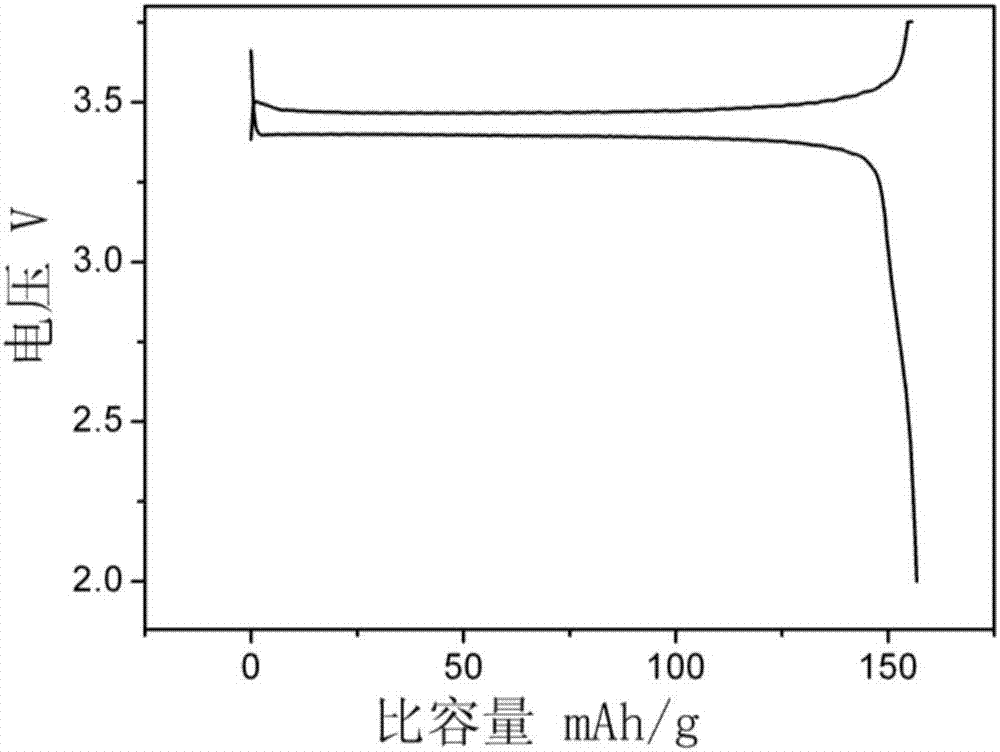

[0039] Using N-methylpyrrolidone as a solvent, stir the powder obtained after sintering with con...

Embodiment 2

[0041] This embodiment provides a method for preparing a lithium-ion battery positive electrode material, the steps are as follows:

[0042] LiOH, Li 2 CO 3 、FePO 4 Mixing was performed at a molar ratio of 0.5:0.25:1. The mixed raw materials were put into a muffle furnace for pre-calcination at 700°C for 4.5h to obtain Li 3 Fe 2 (PO 4 ) 3 and Fe 2 o 3 mixture. After the temperature of the mixture dropped to room temperature, it was put into a mixed solution of deionized water and ethanol at a volume ratio of 1:1 for grinding, the grinding rate was 1000r / min, and FePO 4 Glucose with a mass of 9% was ground at the same rate for 0.5h, and then at a high rate (3000r / min) for 0.5h. After drying, the second sintering was carried out at 700° C. for 6 h in a nitrogen atmosphere to obtain LFP / C.

[0043] Refer to Example 1 for the battery preparation process.

Embodiment 3

[0045] This embodiment provides a method for preparing a lithium-ion battery positive electrode material, the steps are as follows:

[0046] Will Li 2 CO 3 , Fe 4 (P 2 o 7 ) 3 and Fe 2 o 3 Mixing was carried out in a molar ratio of 3:1:1. The mixed raw materials were put into a muffle furnace and pre-fired at 500 °C for 5 hours to obtain Li 3 Fe 2 (PO 4 ) 3 and Fe 2 o 3 mixture. After the temperature of the mixture dropped to room temperature, it was put into methanol and ground at a grinding rate of 1000r / min, and Fe was added after 0.5h. 4 (P 2 o 7 ) 3 10% polyethylene glycol by mass and 5% glucose were ground at the same rate for 0.5 h, and then at a high rate (3000 r / min) for 0.5 h. After drying, the LFP / C was obtained by secondary sintering at 600° C. for 6 h in an argon atmosphere.

[0047] Reference Example 1 for the manufacture of electrode sheet and battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com