Polyolefin resin molded product, method for preparing the same, and air duct using the same

A technology of polyolefin resin and polypropylene resin, which is applied in the field of polyolefin resin molding products and air ducts for preparing and using the products, can solve the problems of inflatable foam air ducts having no hardness and difficulty in manufacturing air ducts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

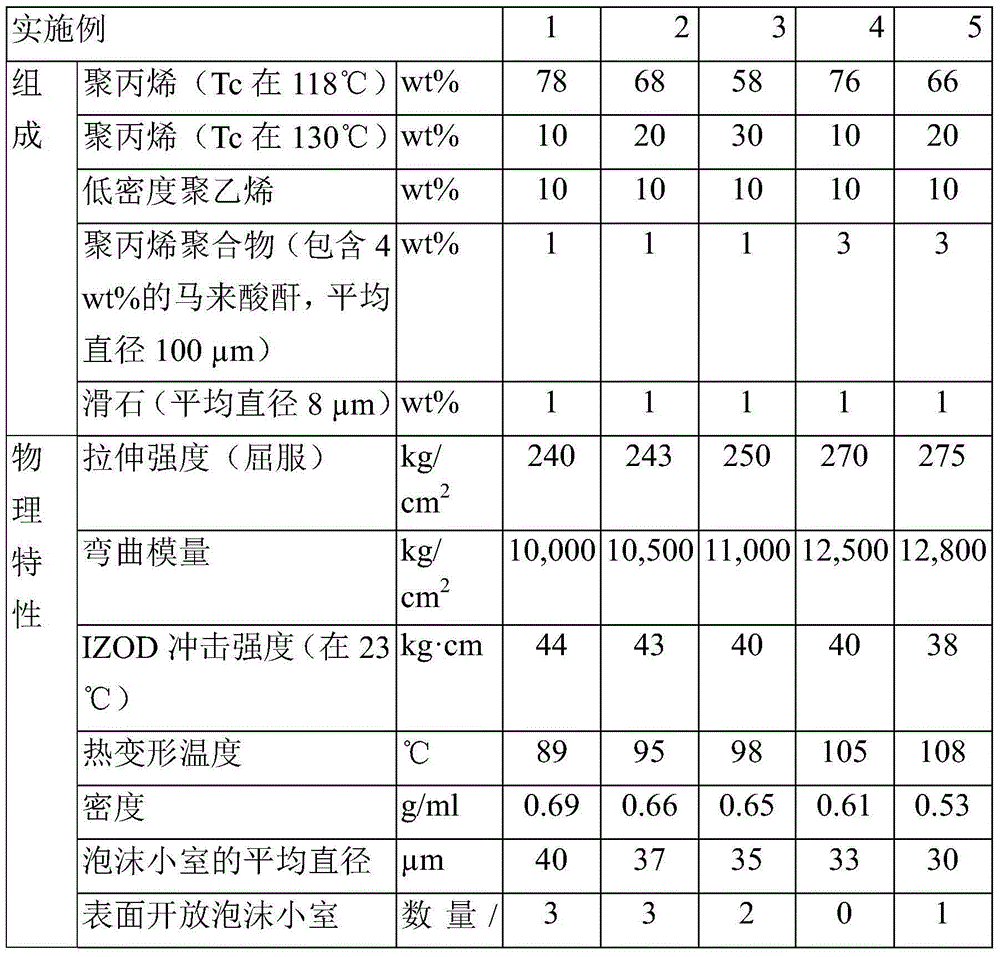

Embodiment 1 to 5

[0122]

[0123] (1) Preparation of polyolefin resin base material

[0124] The reactants were mixed as shown in Table 1 below, and the mixture was introduced into a twin-screw extruder having an L / D (ratio of length to diameter of the screw) of 40 and a screw diameter of 30 mm, and when melted at a temperature of 180° C. The screw was blended at 400 rpm for 35 seconds, and then discharged through a die to prepare a polyolefin resin base.

[0125] (2) Preparation of polyolefin resin molded products

[0126] The polyolefin resin base material is introduced into a blow molding machine together with 3 phr of chemical foaming agent and blow-molded to prepare a polyolefin resin molded product.

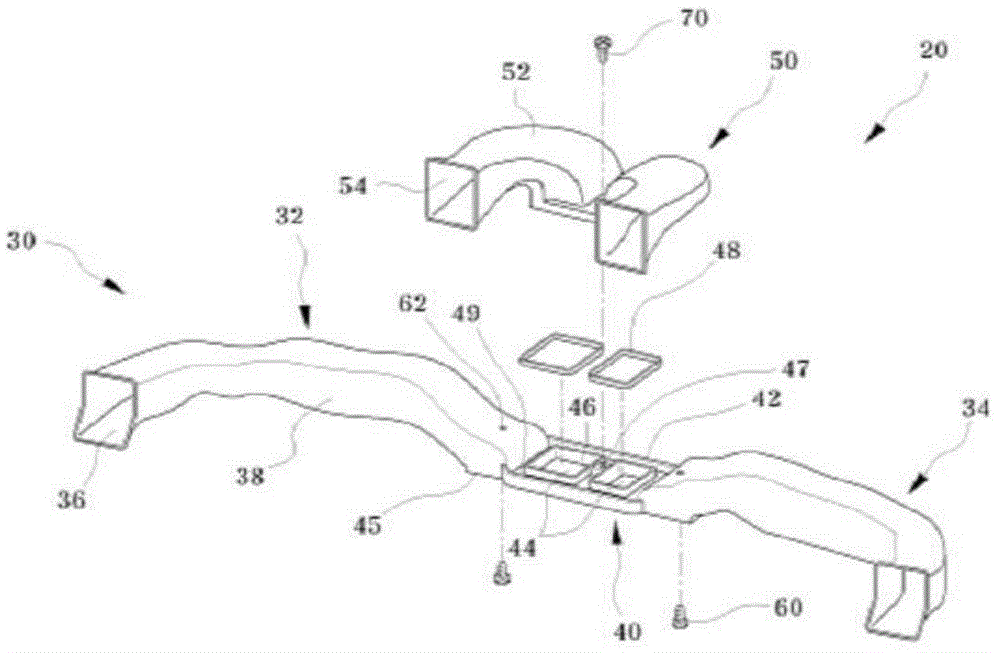

[0127] (3) Preparation of air ducts

[0128] Air ducts are manufactured using polyolefin resin molded products.

experiment example

[0131]

[0132] The physical properties of the polyolefin resin molded products obtained in Examples and Comparative Examples were measured by the following methods, and the results are shown in Table 1 and Table 2 below, respectively.

[0133] 1. Mechanical properties

[0134] 1-1. Tensile strength (kg / cm 2 )

[0135] Samples having a thickness of 1 / 8 inch manufactured using the polyolefin resin molded products obtained in Examples and Comparative Examples were used to measure tensile strength according to the ATSMD638 standard.

[0136] 1-2. Flexural modulus (kg / cm 2 )

[0137] Samples having a thickness of 1 / 8 inch manufactured using the polyolefin resin molded products obtained in Examples and Comparative Examples were used to measure flexural modulus according to ATSMD790.

[0138] 1-3. IZOD impact strength (kg cm)

[0139] Samples having a thickness of 1 / 8 inch manufactured using the polyolefin resin molded products obtained in Examples and Comparative Examples we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com