Offset printing ink and preparation method thereof

An offset printing and ink technology, applied in the field of offset printing ink and its preparation, can solve the problem of high luminous brightness, achieve the effects of high luminous brightness, good dispersion stability, good social value and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

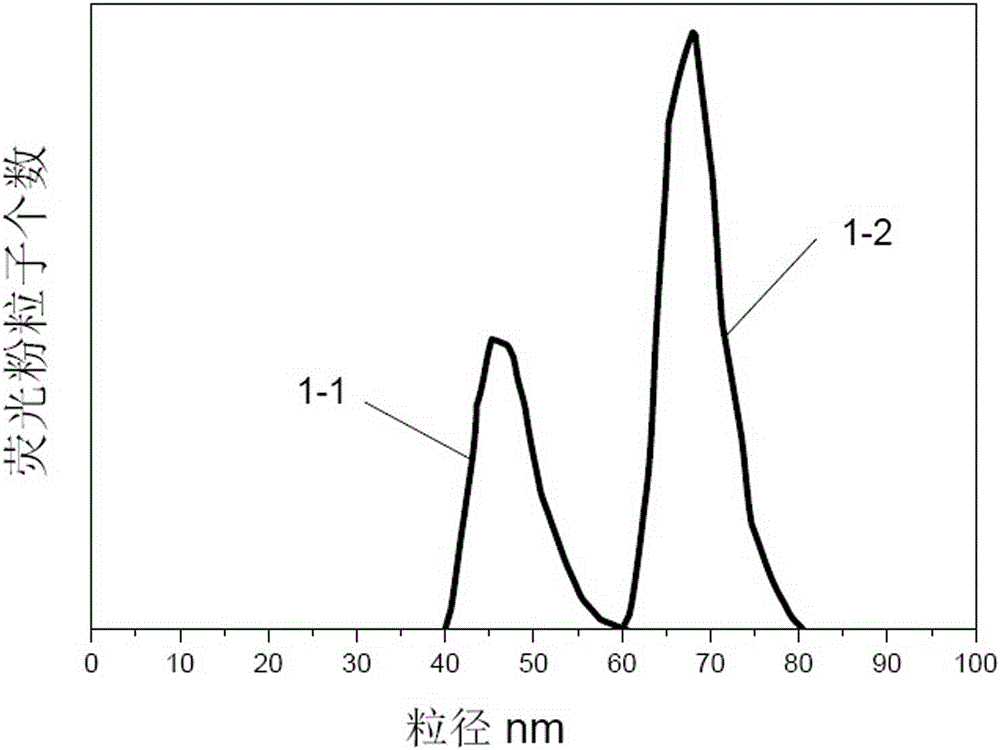

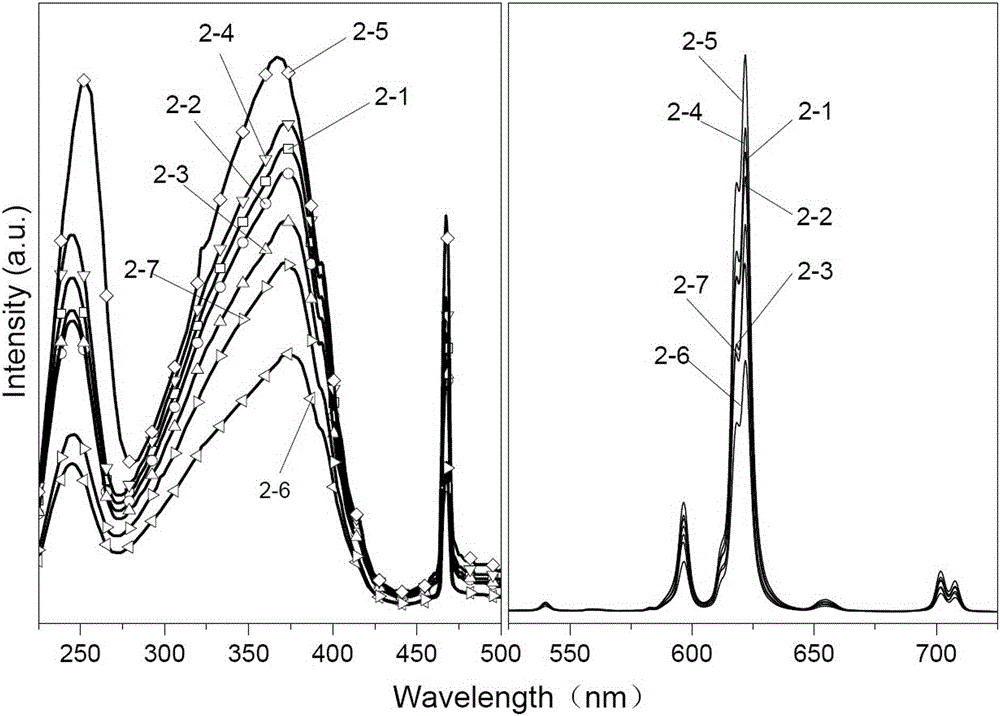

[0013] 1. Preparation of YVO 4 :Eu 3+ ,Sr 2+ Nano phosphor

[0014] (1) Add 1.2mmolNa 3 VO 4 12H 2 O was dissolved in a mixed solution containing 5ml ethylene glycol and 2ml distilled water; (2) The above solution was ultrasonically stirred (80KHz ultrasonic vibration and 300r / min centrifugal speed stirring) and added dropwise with a certain proportion of 1.5mmol Y ( NO 3 ) 3 ·6H 2 O,Eu(NO 3 ) 3 ,Sr(NO 3 ) 2 (0.9:0.03:0.07) in 8ml of ethylene glycol solution, then ultrasonically stirred (80KHz ultrasonic vibration and 300r / min centrifugal speed stirring) for 10min until the solution was clear, then added 20ml of distilled water; (3) Pour the reaction solution into a volume of 50ml In a polytetrafluoroethylene-lined autoclave, in a vacuum environment, 200 o C under heat preservation reaction 1h, down to 150 o C under insulation reaction 1h, after the end of the reaction, cooled to room temperature. The resulting suspension was poured out, centrifuged and washed 3...

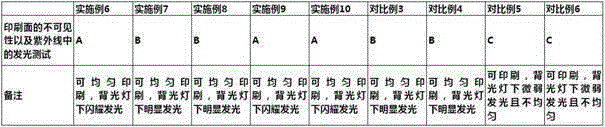

Embodiment 2

[0022] On the basis of embodiment 1, the YVO in the step 3 4 :Eu 3+ ,Sr 2+ with YVO 4 :Eu 3+ , Bi 3+ The weight ratio is changed to 1:0.5, and the rest are the same as in Example 1.

Embodiment 3

[0024] On the basis of embodiment 1, the YVO in the step 3 4 :Eu 3+ ,Sr 2+ with YVO 4 :Eu 3+ , Bi 3+ The weight ratio was changed to 1:0.001, and the rest were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com