Permeable terrace brick manufacturing method

A technology of floor tiles and floor tiles, which is applied in the direction of chemical instruments and methods, pavement paved with prefabricated blocks, layered products, etc., can solve the problems of large proportion, poor strength, low technical content, etc., and achieve light weight, durability Good abrasion resistance, high compressive and bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation process of the adhesive is as follows: stirring the solvent-free epoxy resin, adding the solvent-free epoxy curing agent at the same time, continuing to stir until the mixture is uniform, and then aging for 15-30 minutes.

[0040] Alternatively, the preparation process of the adhesive is as follows: stirring the polymer polyol, adding the solvent-free polyurethane curing agent at the same time, continuing to stir until the mixture is uniform, and aging for 15-30 minutes.

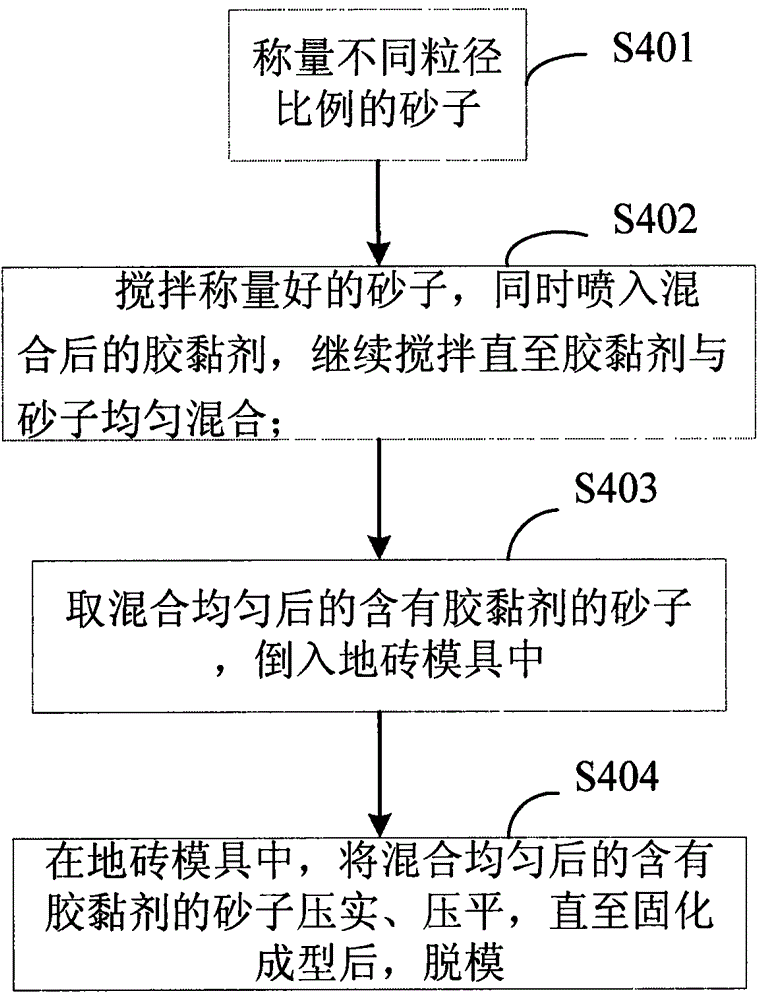

[0041] The method also includes the steps of:

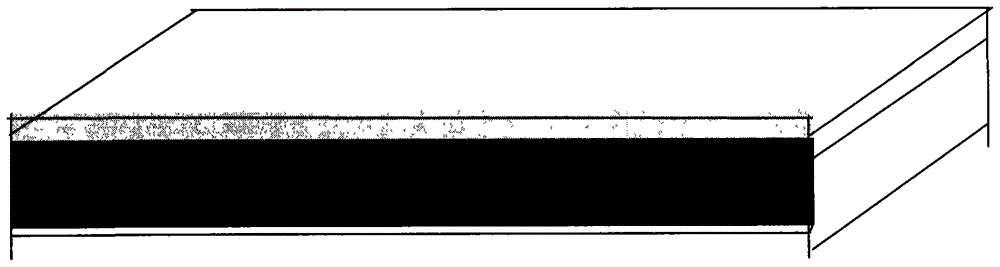

[0042] In the floor tile mould, the lower part whose thickness accounts for 4 / 5 uses the sand that is uniformly mixed and contains a mixture of solvent-free epoxy resin and solvent-free epoxy curing agent as an adhesive, and the thickness accounts for 1 / 5. The upper part adopts sand that is uniformly mixed and contains a mixture of polymer polyol and solvent-free polyurethane curing agent as an adhesive.

Embodiment 1

[0045] According to weight percentage: 3-6 parts, 1.5-3 parts of solvent-free epoxy curing agent, 91-95.5 parts of dust-free high-hardness sand with a particle size of 1-3mm, weighed well;

[0046] Slowly add solvent-free epoxy curing agent to solvent-free epoxy resin under stirring, and mature for 15-30min;

[0047] While stirring the sand, spray the mixed adhesive at the same time and stir evenly;

[0048] Take the evenly mixed sand containing adhesive and pour it into the floor tile mould;

[0049] In the floor tile mould, the uniformly mixed sand containing the adhesive is compacted and flattened until it is solidified and formed, and then demolded.

Embodiment 2

[0051]According to weight percentage: 2-5 parts of solvent-free epoxy resin, 1-2.5 parts of solvent-free epoxy curing agent, 92.5-97 parts of 4-6mm dust-free high-hardness sand, weighed well;

[0052] Slowly add solvent-free epoxy curing agent to solvent-free epoxy resin under stirring, and mature for 15-30min;

[0053] While stirring the sand, spray the mixed adhesive at the same time and stir evenly;

[0054] Take the evenly mixed sand containing adhesive and pour it into the floor tile mould;

[0055] In the floor tile mould, the uniformly mixed sand containing the adhesive is compacted and flattened until it is solidified and formed, and then demolded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com