A uniform automatic feeding device for a large melting furnace

An automatic feeding device and melting furnace technology, applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of feeding time, quantity, unbalanced position, large impact force on the inner wall of the melting furnace, and reduced service life of equipment, etc. To achieve the effect of being conducive to heat, reducing element burning loss, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

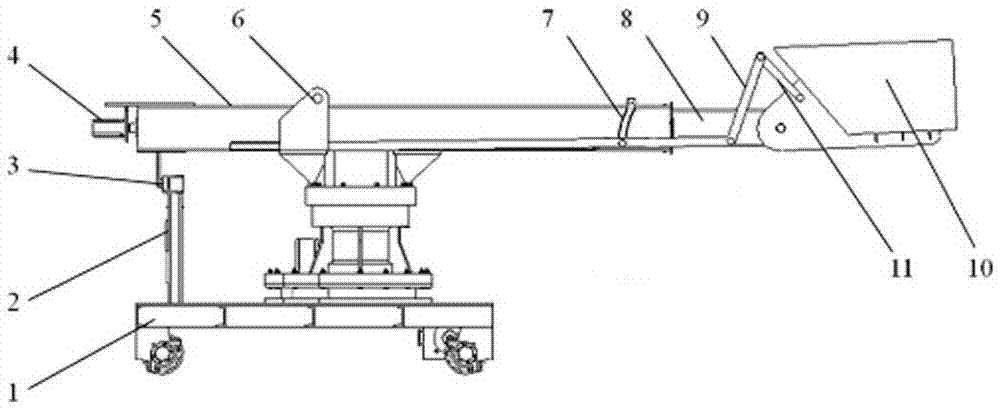

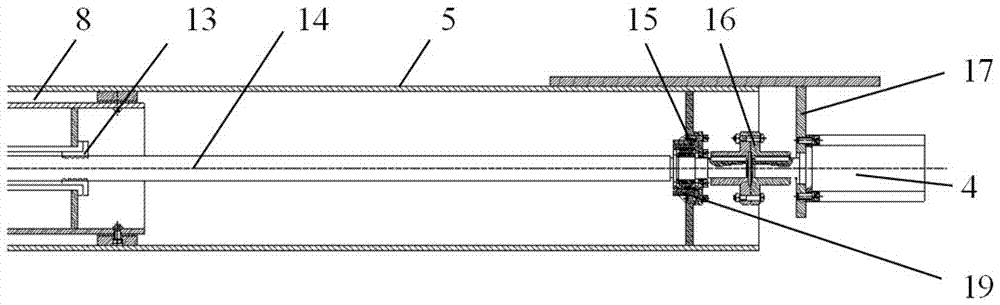

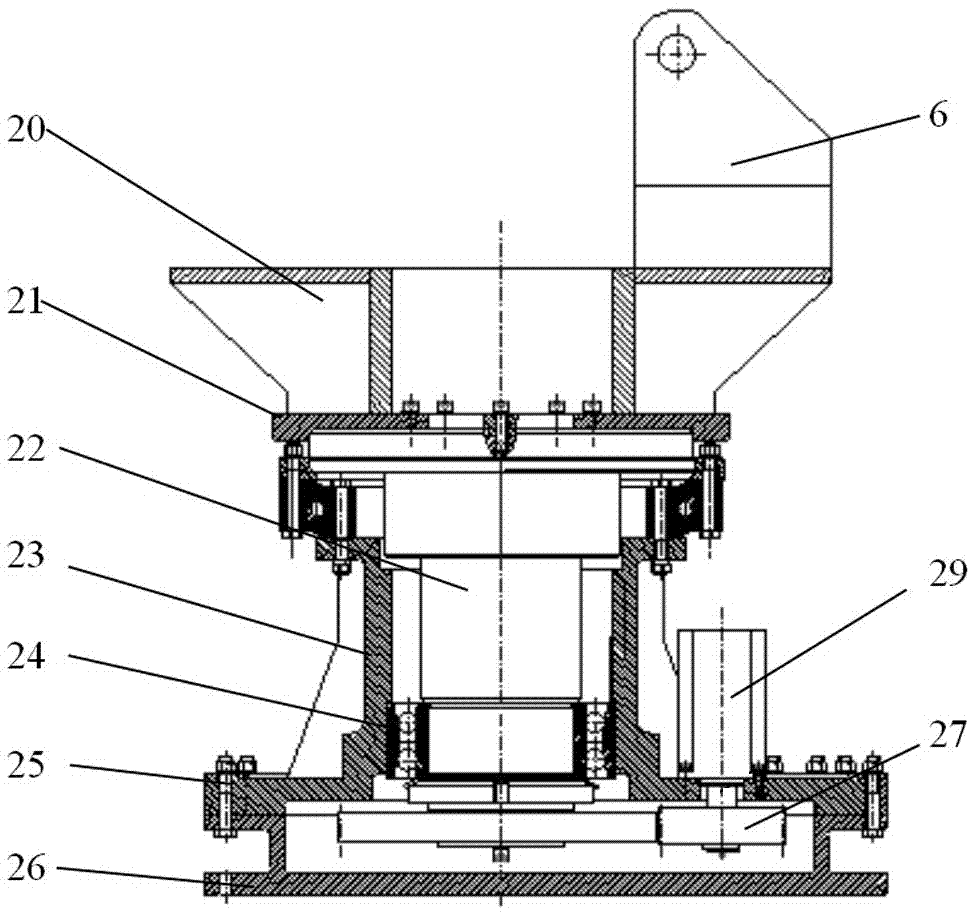

[0021] Such as Figure 1-Figure 4 As shown, the present invention is mainly made up of telescopic loading arm, hopper 10, deflection mechanism. The telescopic loading arm is a telescopic movable structure. The rear part of the telescopic loading arm is fixed by an anti-overturning device, and the front part can be stretched back and forth. The telescopic position of the front part of the telescopic loading arm can be controlled by a stepping motor and a screw nut mechanism, such as figure 2 shown. Specifically, the telescopic loading arm is arranged on the first-level telescopic arm support 6, the first-level telescopic arm support 6 is arranged on the deflection mechanism 21, the lower end of the first-level telescopic arm support 6 is a connecting frame 20, and the lower end of the connecting frame 20 is arranged on the deflection mechanism 21 on. The telescopic loading arm includes a telescopic arm sleeve 5 arranged on the primary telescopic arm bracket 6, a secondary te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com