A fiber grating-based GMA self-adaptive control method and device

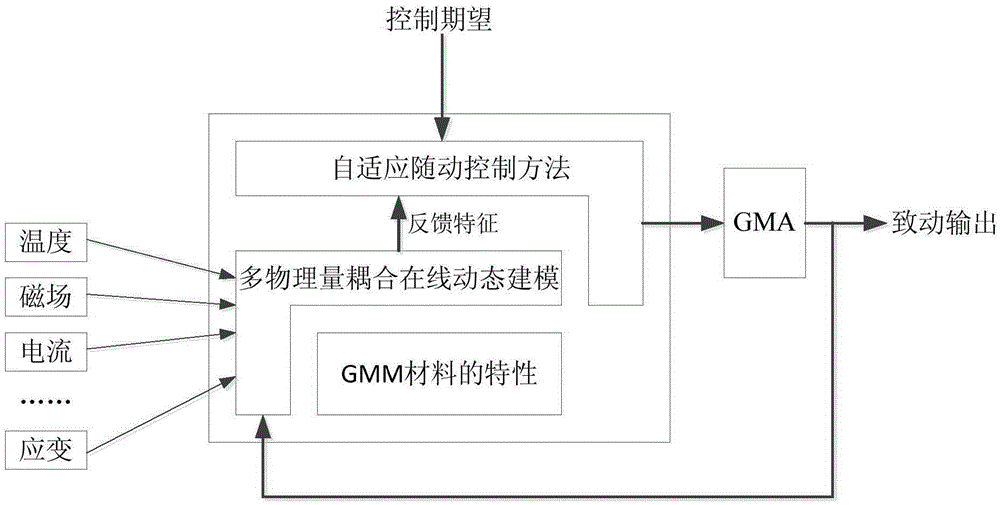

A technology of adaptive control and fiber grating, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the lack of constitutive model, lack of GMA multi-physics factor action characteristics, coupling mechanism and dynamic nonlinearity Characteristics and other issues to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

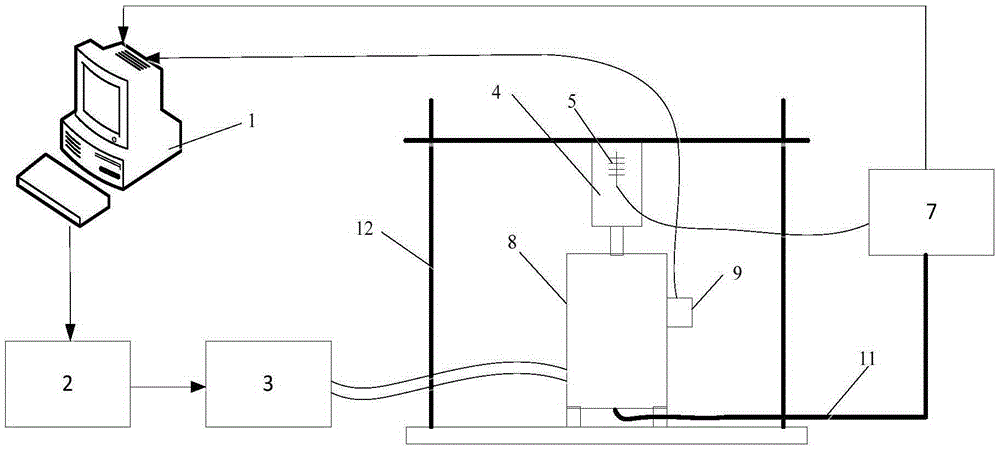

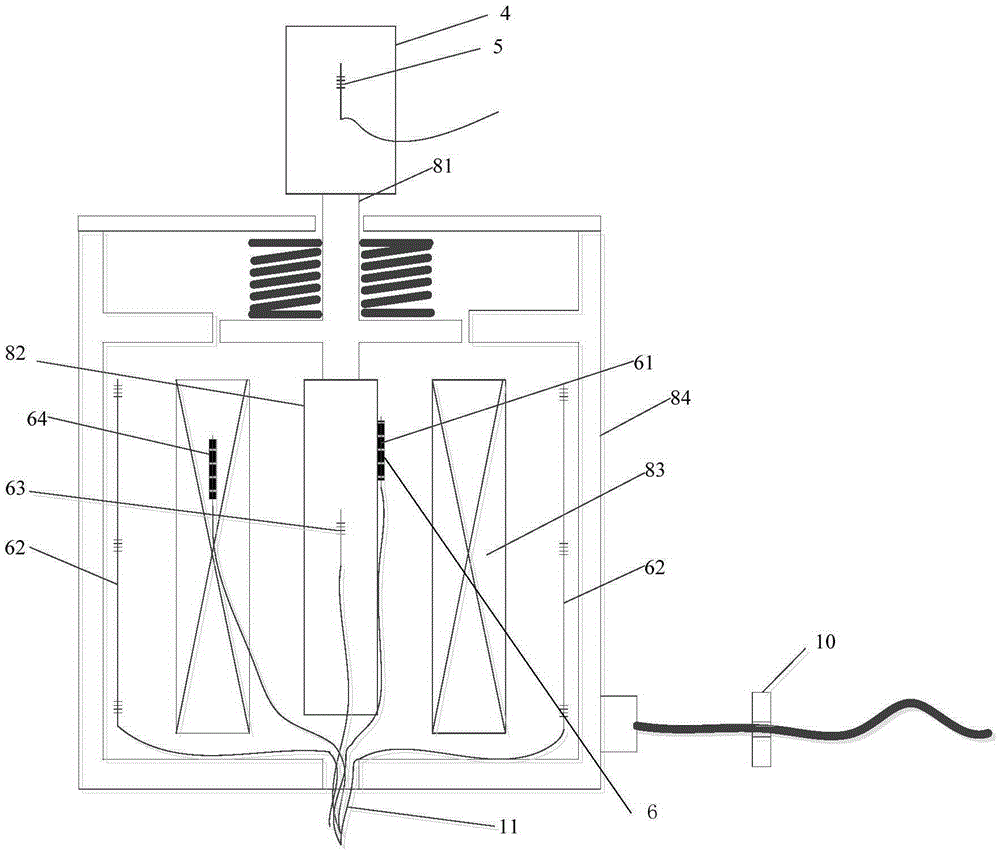

[0042] Such as figure 1 with figure 2 As shown, a GMA adaptive control method device based on fiber grating of the present invention includes a PC 1, a signal generator 2, an audio power amplifier 3, a strain body 4 tightly connected to an actuating rod 81 of GMA 8, and a strain body 4 The closely connected grating displacement sensor 5, the environmental physical quantity grating sensor 6, the grating demodulator 7, the environmental temperature sensor 9, the current sensor 10 and the experimental support 12 installed inside the GMA8. The various components of the GMA8 system are fixed on the experimental support 12.

[0043] The GMA8 system can be driven statically by a direct-flow control power supply, or dynamically driven by a signal generator 2 and an audio power amplifier 3. The grating displacement sensor 5 and the strain body 4 and the envir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com