Steel tracking and identification system

A technology for tracking and identifying steel products, which is applied in the direction of instruments, inductive record carriers, and calculations. It can solve the problems of being unable to determine the orientation or exact position of the RFID tag read, and achieve the effect of realizing automated operations and reducing human operation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

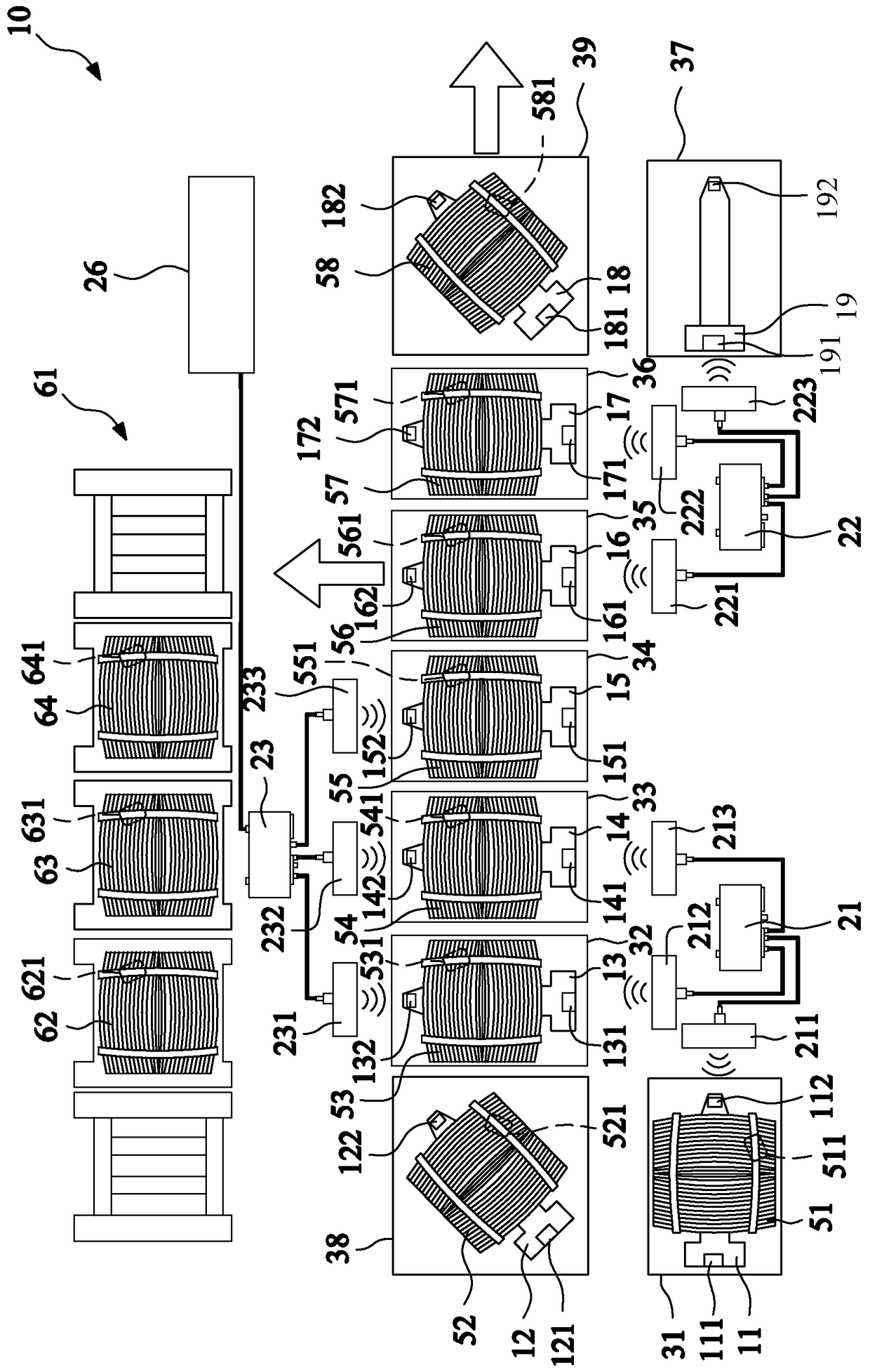

[0040] figure 1 A schematic diagram showing an embodiment of the steel product tracking and identification system of the present invention. The steel product tracking and identification system 10 of the present invention includes: a plurality of carrying devices 11, 12, 13, 14, 15, 16, 17, 18, 19, a plurality of RFID readers 21, 22, 23 and a controller 26 . The carrying devices 11 , 12 , 13 , 14 , 15 , 16 , 17 , 18 , 19 are respectively arranged in a plurality of identification areas 31 , 32 , 33 , 34 , 55 , 36 , 37 , 38 , 39 . In one embodiment, the carrying device is a hook, and may also be a carrying pallet or a carrying trolley.

[0041] Each of the carrying devices includes at least one carrying RFID tag, which is arranged on one side of the carrying device. The carrying device is used to carry the steel products 51, 52, 53, 54, 55, 56, 57, 58, and the steel products 51, 52, 53, 54, 55, 56, 57, 58 respectively have a steel product RFID Tags 511, 521, 531, 541, 551, 56...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com