Cleaner dedicated to electrode foil production

A cleaning device and electrode foil technology, applied in the direction of liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of reduced startup productivity, production troubles, inconvenience, etc., to improve production efficiency, clean The effect of less use time and avoiding downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

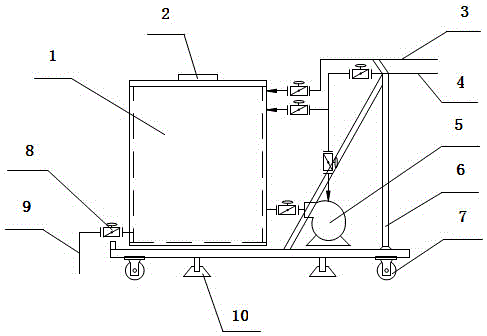

[0011] As an embodiment of the present invention, such as figure 1 As shown, a special cleaner for electrode foil production includes a cleaning agent storage tank 1, the cleaning agent storage tank 1 is set on a manual cart 6, and the bottom of the manual cart 6 is provided with a universal wheel 7 and a foot cup 10. The universal wheel 7 facilitates the movement of the present invention. After being moved in place, it can be fixed by the foot cup 10, which has good practicability. In this embodiment, as a preference, there are four universal wheels 7, which are respectively arranged at the four corners of the bottom of the manual cart 6, and there are two foot cups 10, which are symmetrically arranged at the bottom of the manual cart 6 . The cleaning agent storage tank 1 is respectively provided with a cleaning return pipe 3 and a cleaning outlet pipe 4, and the cleaning outlet pipe 4 is connected with the cleaning agent storage tank 1 through a magnetic pump 5; A discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com