Package apparatus and manufacturing method thereof

A technology for packaging devices and manufacturing methods, which is applied in the fields of printed circuit manufacturing, semiconductor/solid-state device manufacturing, and printed circuits. It can solve problems such as expensive substrates, lack of industrial advantages, and restrictions on substrates with high-density wiring, so as to improve production. ability, shorten the center distance, and the effect of wide line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

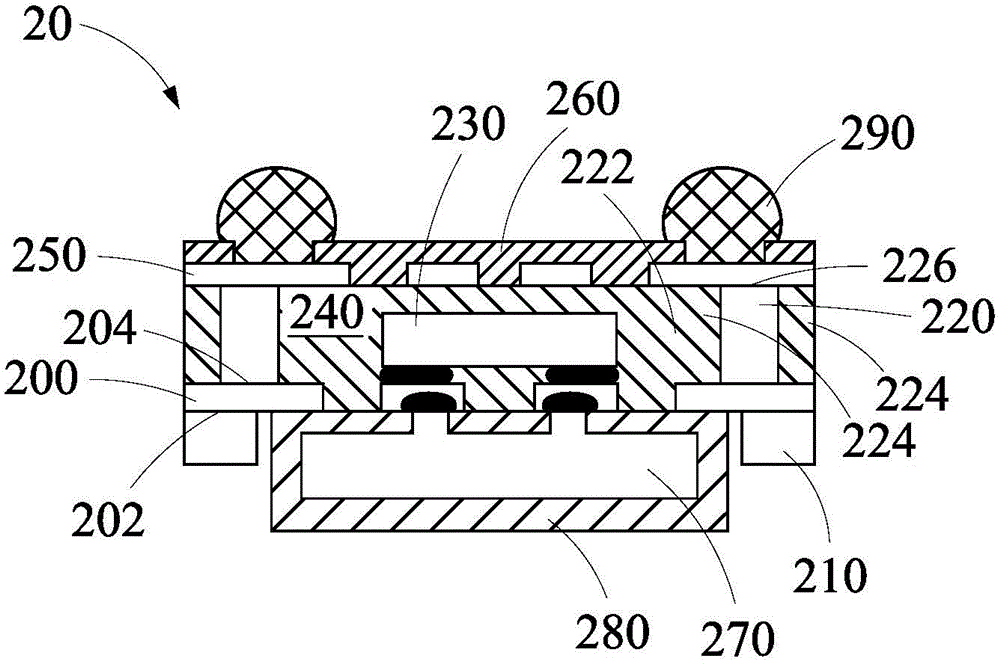

[0069] figure 2 It is a schematic diagram of a packaging device in a preferred embodiment of the present invention. The packaging device 20 includes a first wire layer 200, a metal layer 210, a first conductive column layer 220, an internal connection element 230, a first mold compound layer 240, a second wire layer 250 and a solder mask Layer 260, but not limited thereto.

[0070] The first wire layer 200 has a first surface 202 and a second surface 204 opposite to each other. In this embodiment, the first wire layer 200 is formed by using electrolytic plating technology, but it is not limited thereto. The first wiring layer 200 may be a patterned wiring layer, which includes at least one wire or at least one chip seat, and the material of the first wiring layer 200 may be metal, such as copper. The metal layer 210 is disposed on the first surface 202 of the first wire layer 200 .

[0071] The first conductive column layer 220 is disposed on the second surface 204 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com