A method for placing a spaceship payload

A spaceship and payload technology, applied in position/direction control, aircraft, lighter-than-air aircraft, etc., to achieve the effect of reducing control difficulty, reducing moment of inertia, and reducing center distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] (1) Cargo spacecraft cargo storage structure and constraints

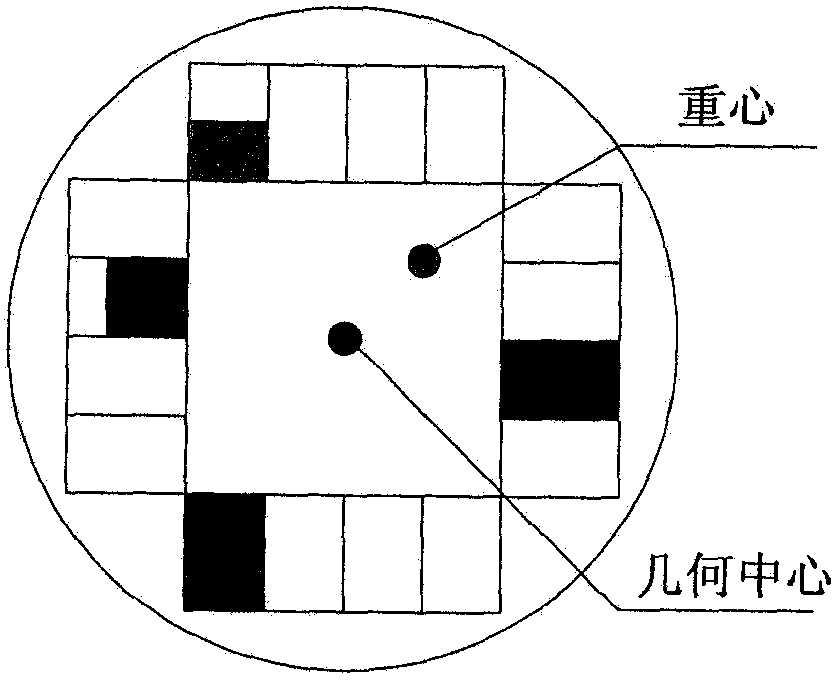

[0023] In addition to storing cargo bags, cargo spaceship shelves can also place lockers, drawers and other storage structures, such as figure 1 As shown, the following constraints are established for the cargo placement of the cargo spacecraft:

[0024] 1. The center of gravity of the loading cargo substructure to be placed can only be located in the storage position of the substructure.

[0025] 2. Only the substructure of the same type and specification can be exchanged. For example, a drawer can only be exchanged with a drawer of the same specification, but the quality of the goods stored in the drawer can be different.

[0026] 3. Each cargo loading substructure is in a discrete state without overlapping.

[0027] 4. The distance between the center of gravity and the geometric center is required to be less than 25mm.

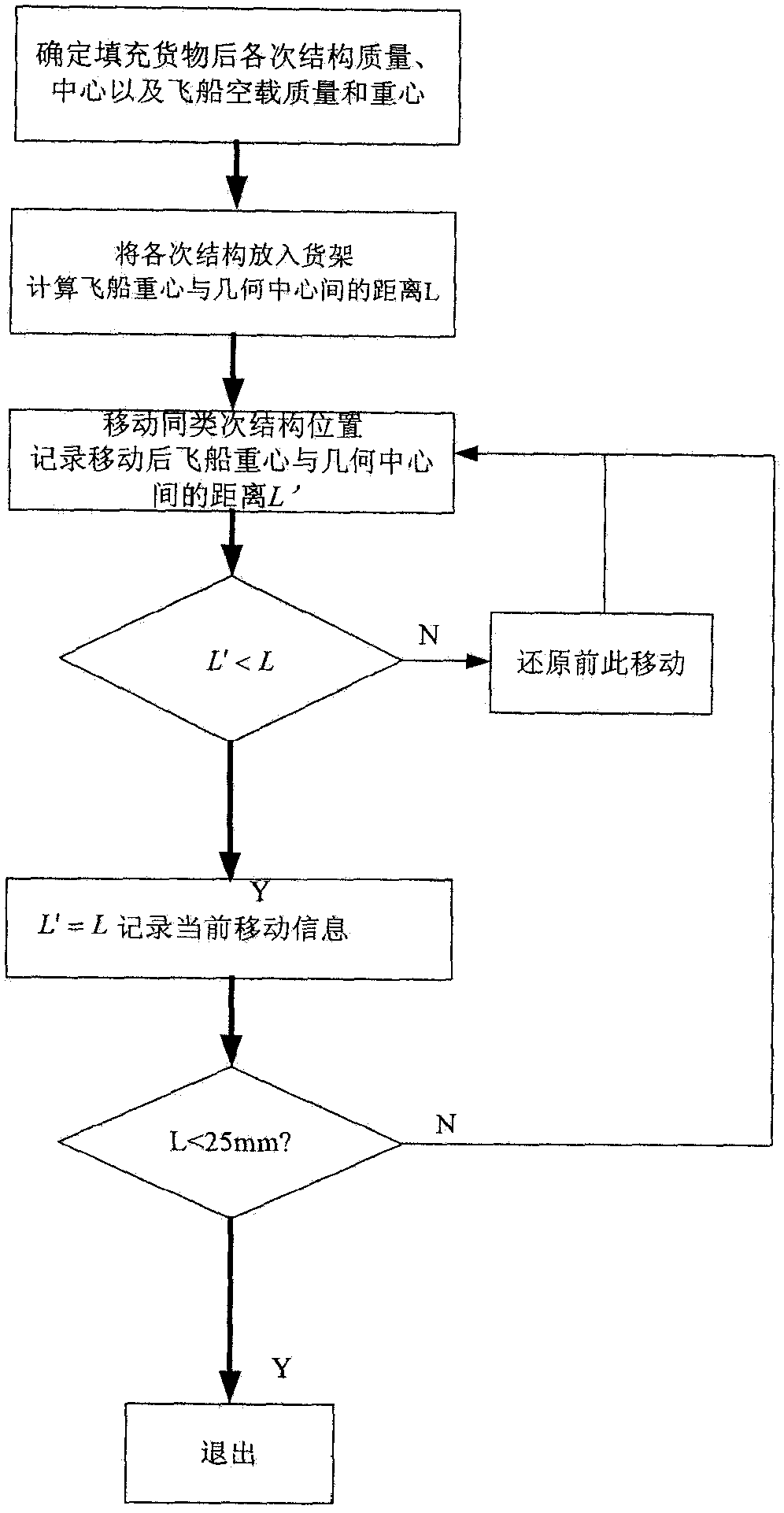

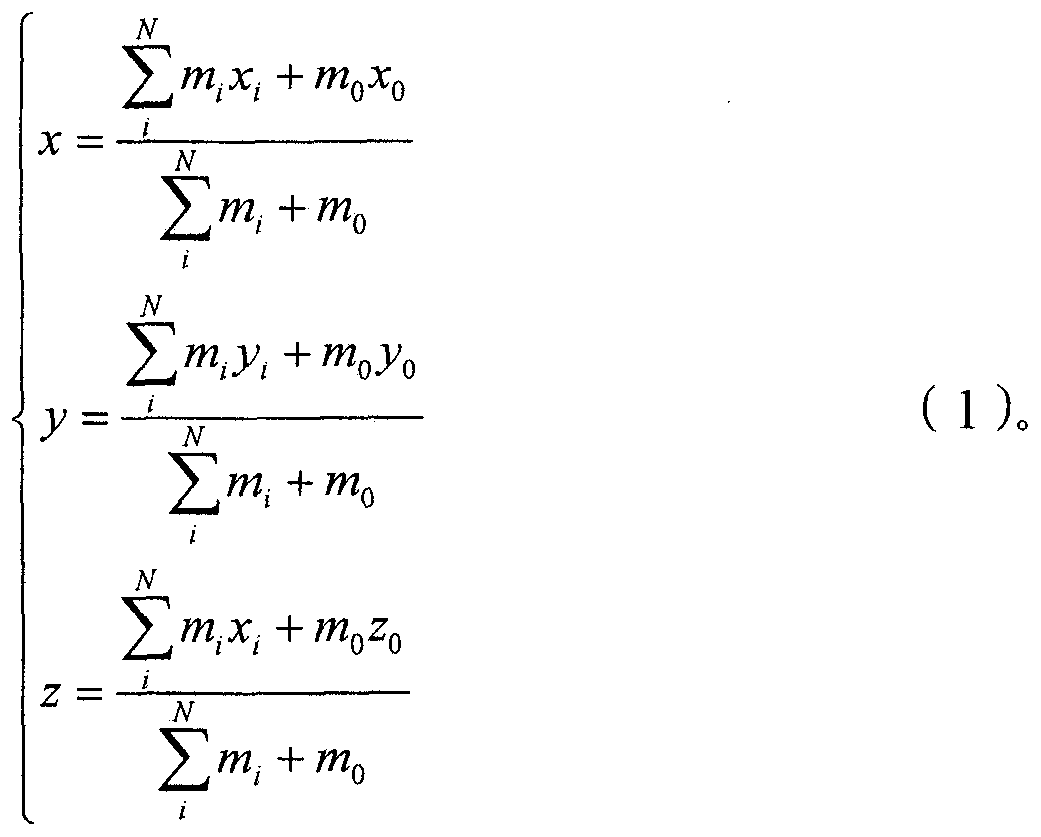

[0028] (2) Cargo spaceship cargo layout optimization algorithm

[0029] Cargo loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com