Control method for continuous rolling of wire rods and bars

A control method, rod and wire technology, applied in metal rolling, tension/pressure control, etc., can solve the problems of small cross-sectional size of rolled pieces, low efficiency of tension adjustment, and long debugging process, so as to reduce product waste , Release the workload and improve the operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

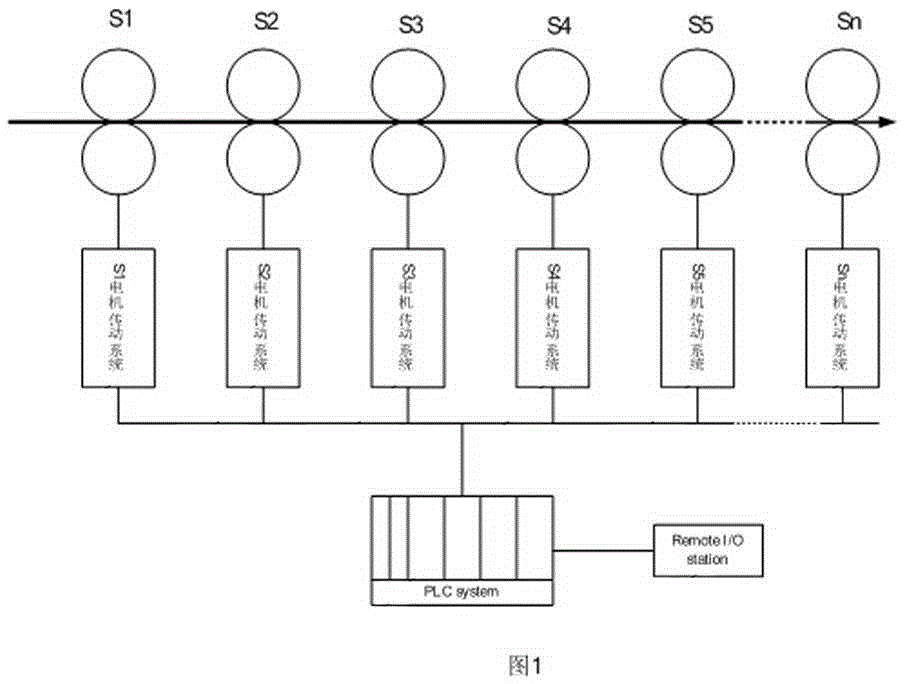

[0067] Such as figure 1 , figure 2 and Figure 4 Shown, S i is the continuous rolling stand number, i is 1, 2, 3, 4, ..., n, 21, 22, 23, 24, 25, 26 are frequency conversion devices, 30 is the communication network, 40 is the PLC control system, 41 is the remote I / O Substation. The exchange of data (such as speed, rolling torque, etc.) between the PLC control system 40 and the frequency conversion devices 21 , 22 , 23 , 24 , 25 , 26 is transmitted through the communication network 30 .

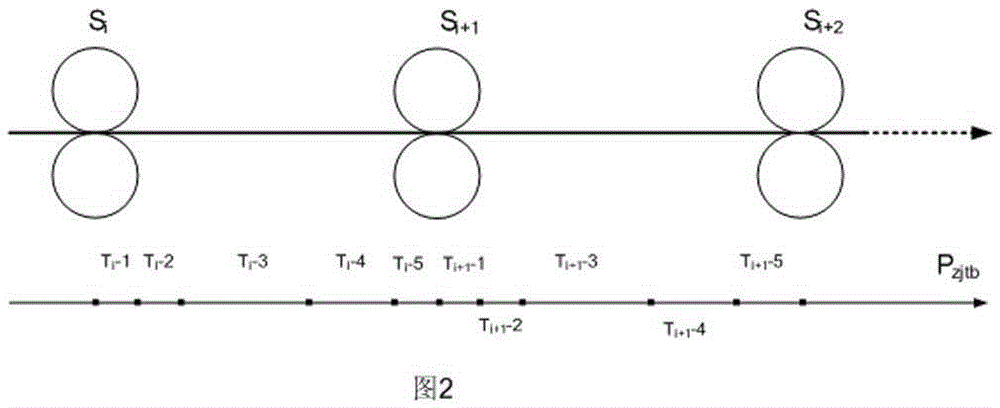

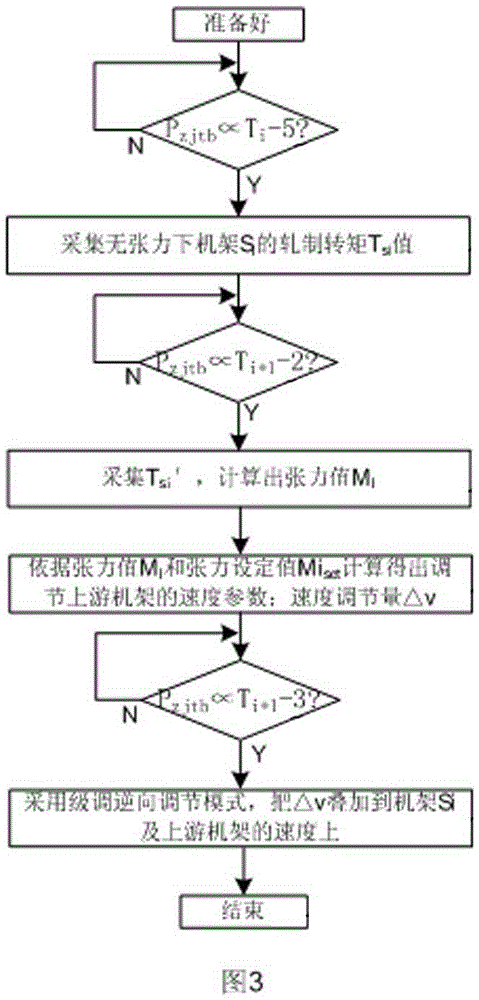

[0068] T i -1,T i -2,T i -3,T i -4,T i -5, is the head P of the rolled piece zjtb This time period is automatically calculated by the control system via the time segment of the area. where T i+1 -1 time period for mill S i+1 Bite steel stage, T i+1 -2 time period for the rolled piece biting into the stand S i+1 after mill s i Rolling torque sampling, tension and adjustment calculation stage, T i -3 is the tension adjustment stage, T i+1 -4 is the rolling mill speed recovery s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com