Fiber laser welding method for liquid crystal display bracket

A liquid crystal display, fiber laser technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of molten pool metal pollution, easy welding penetration of bracket corners, large heat affected zone, etc., to improve enterprise production efficiency, The effect of reducing production cost and ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

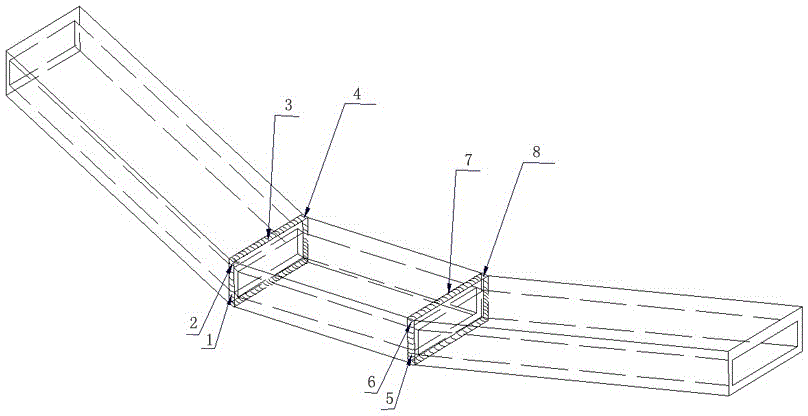

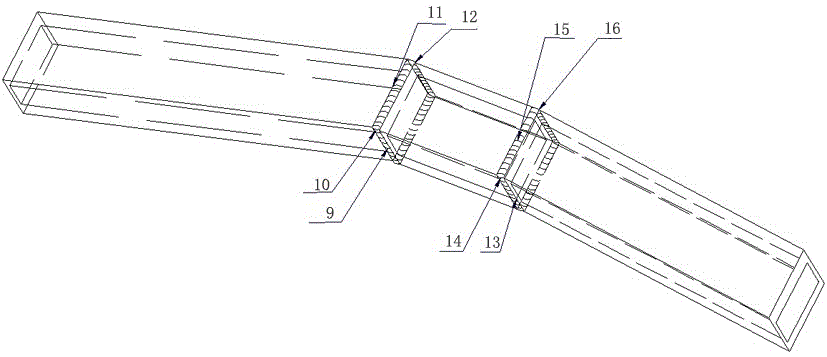

[0025] Such as figure 1 As shown, the bracket is composed of three sections of square tubes, the material of which is preferably Q195 carbon structural steel, and the thickness of the tube wall is more than 1.5mm. The blanking of the square tubes is formed by wire cutting. The gap at the center is less than 0.3mm, three sections of square tubes are butted, the middle section of short square tube is placed horizontally, and the other two sections of long square tubes are inclined at 10° and symmetrically distributed on both sides of the short square tube. Before welding, it is best to clean the oil at 50mm around the weld with alcohol, which can reduce its reflection on the laser, increase the light absorption rate of the workpiece, and increase the penetration depth to ensure welding quality.

[0026] In this embodiment, the IPG YLS-1000 fiber laser is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com