Numerical control machine tool with built-in automatic loading and unloading mechanism and method for loading and unloading workpiece

A technology of unloading mechanism and CNC machine tool, which is applied to metal processing mechanical parts, positioning devices, clamping devices, etc. Simple and convenient manufacturing, low manufacturing cost and high workpiece positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

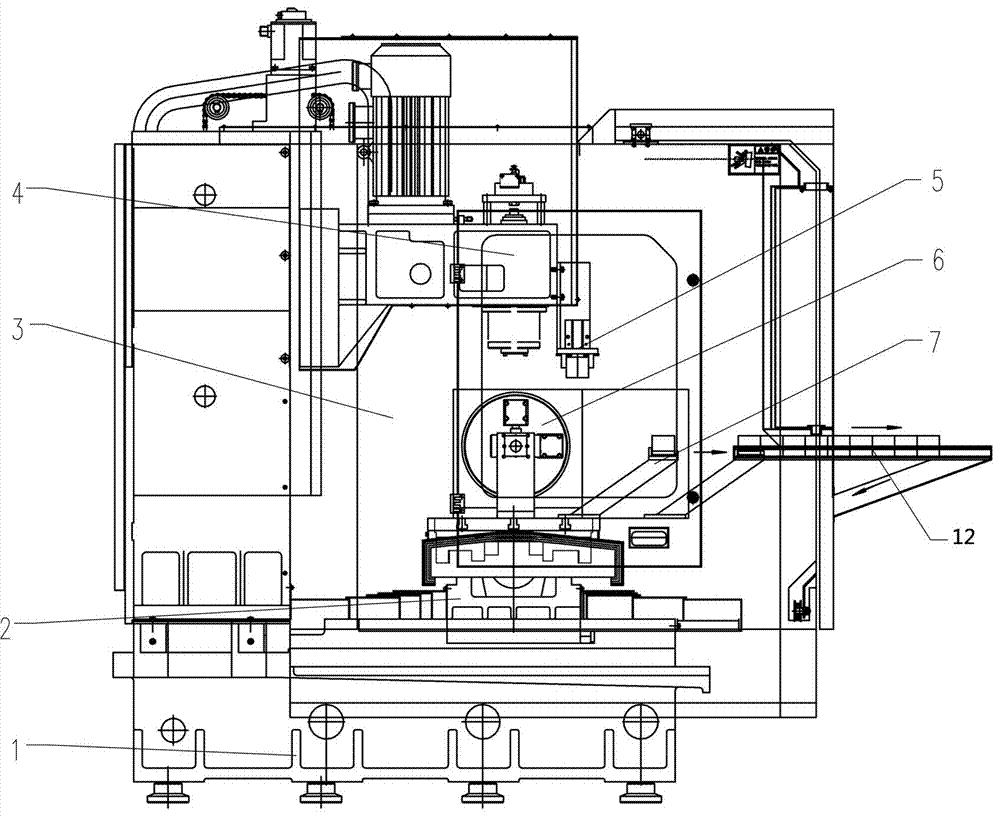

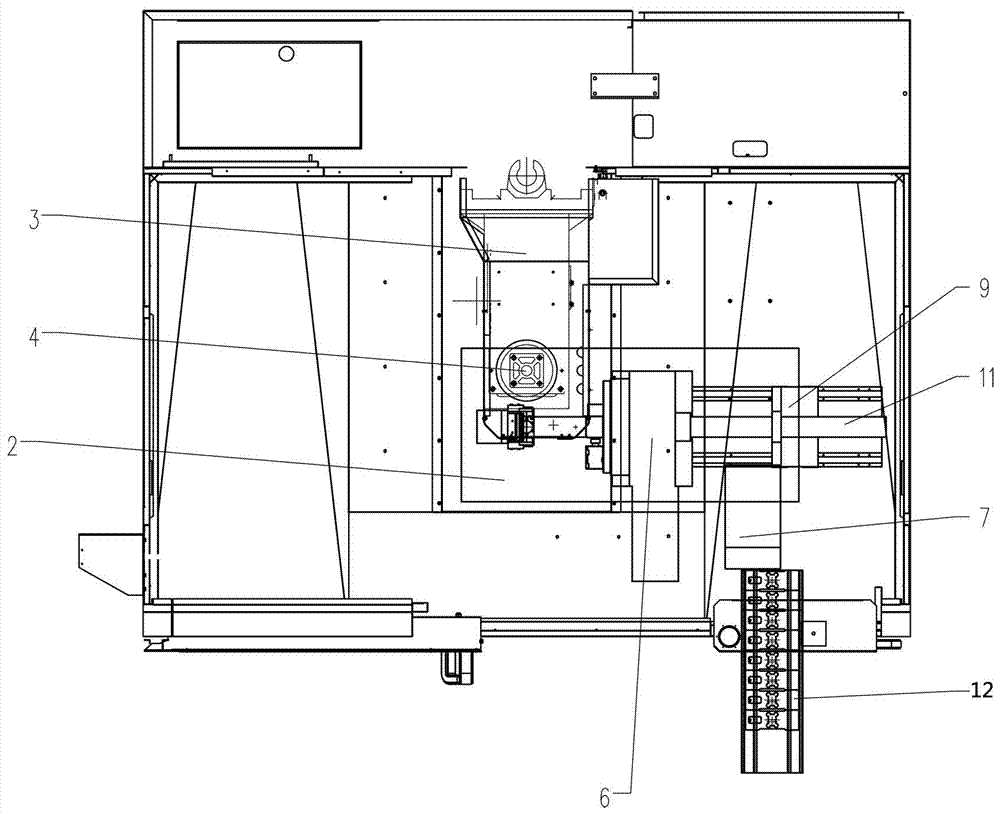

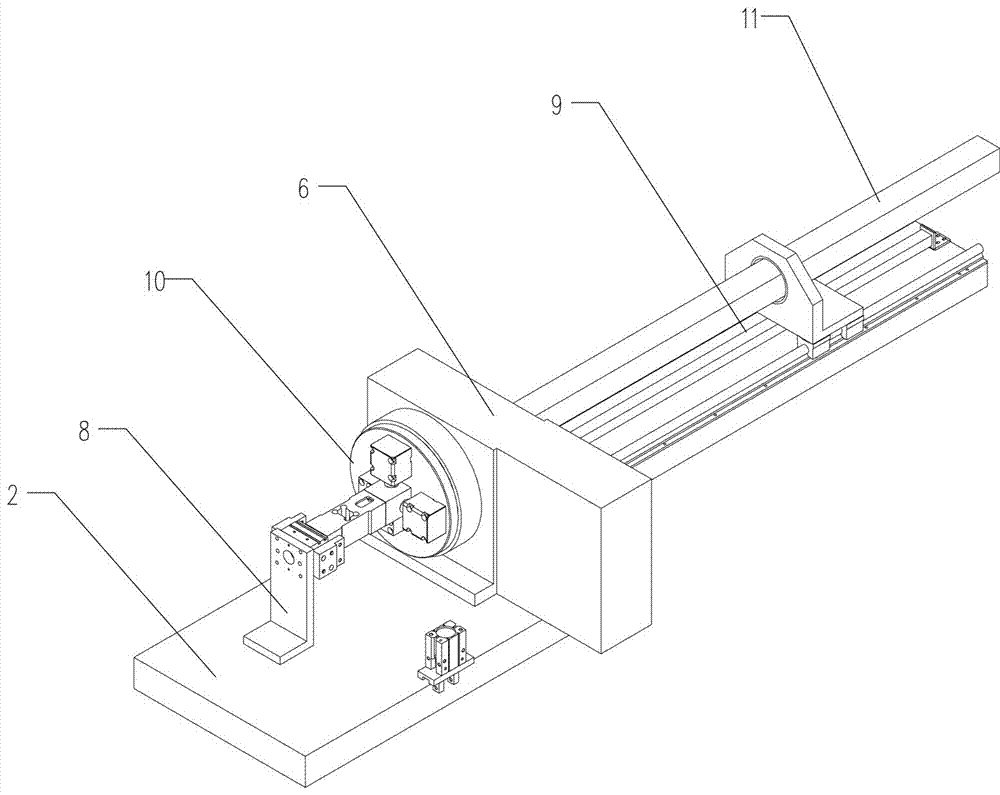

[0035] like figure 1 The CNC machine tool shown is self-equipped with upper and unloading air claws,

[0036] A CNC machine tool with a built-in automatic loading and unloading mechanism includes a machine tool body with a base 1. The base 1 of the machine tool body is also equipped with a worktable 2 and a column 3 that can move along the Y direction and X direction separately or simultaneously. The box 4 is set on the column 3 and can move along the Z direction, and also includes the upper unloading air claw 5, which is arranged on the side of the spindle box 4; the base 1 is equipped with a cross guide rail slide seat, a cross guide rail slide There are linear guide rails in the X direction and Y direction on the top, and the workbench 2 is placed on the linear guide rails to move along the X direction and the Y direction. Two sets of ball screw pairs and matching displacement motors are set between the workbench 2 and the base 1. A linear guide rail is installed on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com