a wrench

A wrench and tooth block technology, applied in the field of wrenches, can solve problems such as inconvenient operation and inability to realize quick opening and closing of jaws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

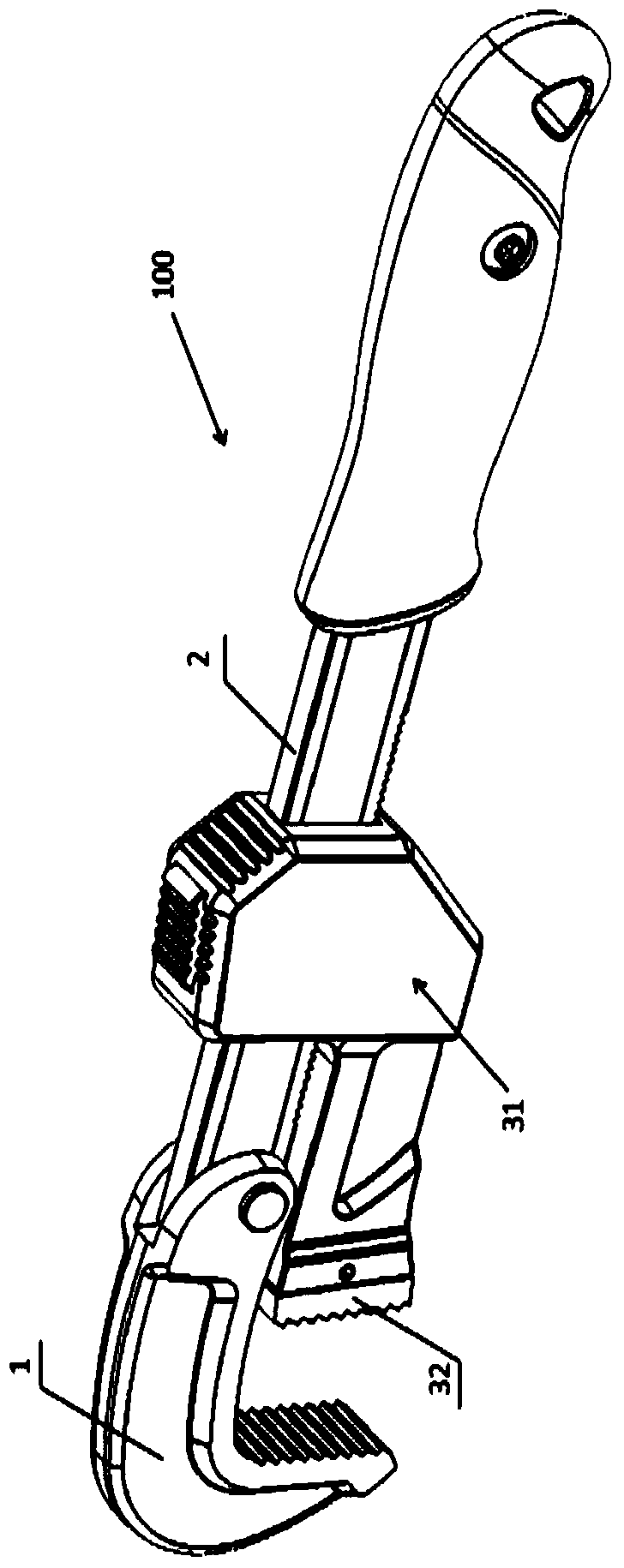

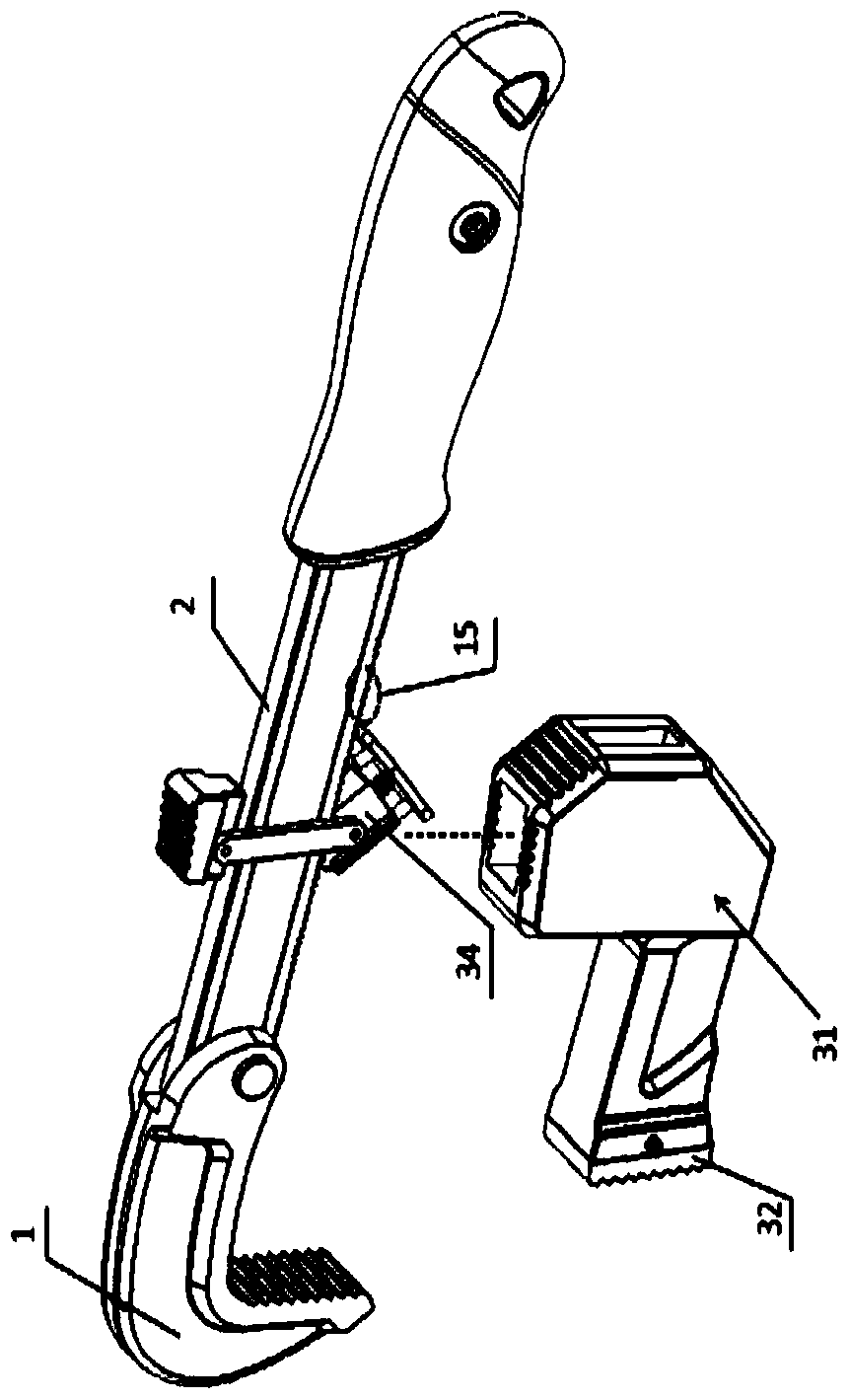

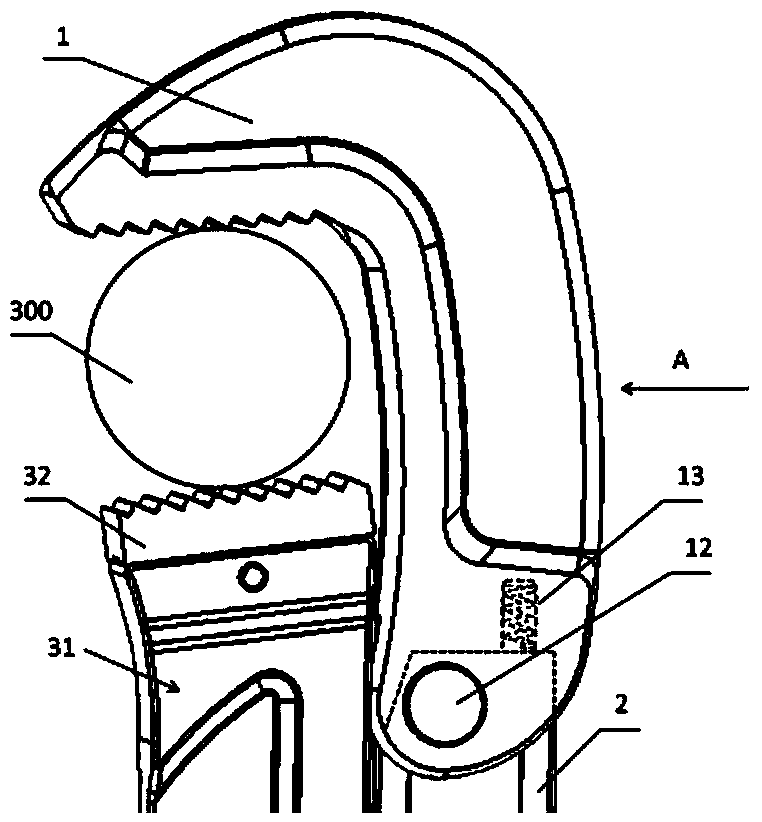

[0060] figure 1 with figure 2 It is a schematic diagram of a wrench 100 in a preferred embodiment of the present invention, and its structure includes: a guide rod 2, a first claw 1 installed on the guide rod 2, a sliding part 31 threaded on the guide rod 2, and an installation On the sliding part 31 and the second claw 32 matched with the first claw 1, the wrench 100 also includes a tooth block 34 arranged inside the sliding part 31 and cooperating with the guide rod 2. The tooth block 34 has a first position and a second position. Location.

[0061] The wrench 100 is configured such that: when the tooth block 34 is in the first position, the tooth block 34 engages with the guide rod 2, the tooth block 34 can slide along the guide rod 2 toward the first claw 1, and moves away from the first claw 1 The direction is locked; when the tooth block 34 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com