Single-pump hydraulic system used for forklift

A hydraulic system and single-pump technology, applied in fluid pressure actuators, lifting devices, servo motors, etc., can solve the problems of inaccurate speed regulation range, rough reversing positioning accuracy, increased engine fuel consumption, etc., and achieve system components Compact, low cost of installation and use, conducive to the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be described below in conjunction with specific embodiments.

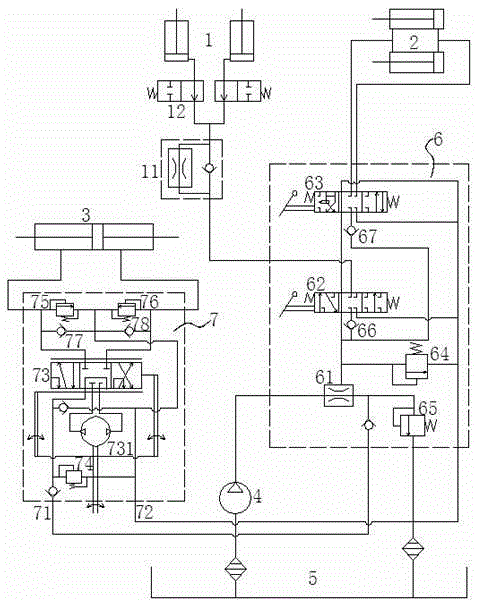

[0030] Such as figure 1 As shown, it is a schematic structural diagram of a single-pump hydraulic system for a forklift provided in this embodiment.

[0031] This embodiment provides a single-pump hydraulic system for forklifts, including a lifting cylinder 1, a tilting cylinder 2, and a steering cylinder 3, and a gear pump 4 that provides high-pressure oil for the lifting cylinder 1, tilting cylinder 2, and steering cylinder 3; it also includes The hydraulic oil tank 5, the multi-way reversing valve 6 and the full hydraulic steering gear 7, the oil inlet end of the gear pump 4 is connected to the oil outlet end of the hydraulic oil tank 5, the oil outlet end of the gear pump 4 is connected to the multi-way reversing valve 6, and multiple The multi-way reversing valve 6 is connected to the oil return end of the hydraulic oil tank 5, the lifting cylinder 1, the tilti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com