Fully-automatic filling assembly line and filling method

An assembly line, fully automatic technology, applied in packaging, bottle filling, liquid bottling, etc., can solve problems such as low production efficiency, waste of time, slow filling and feeding, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

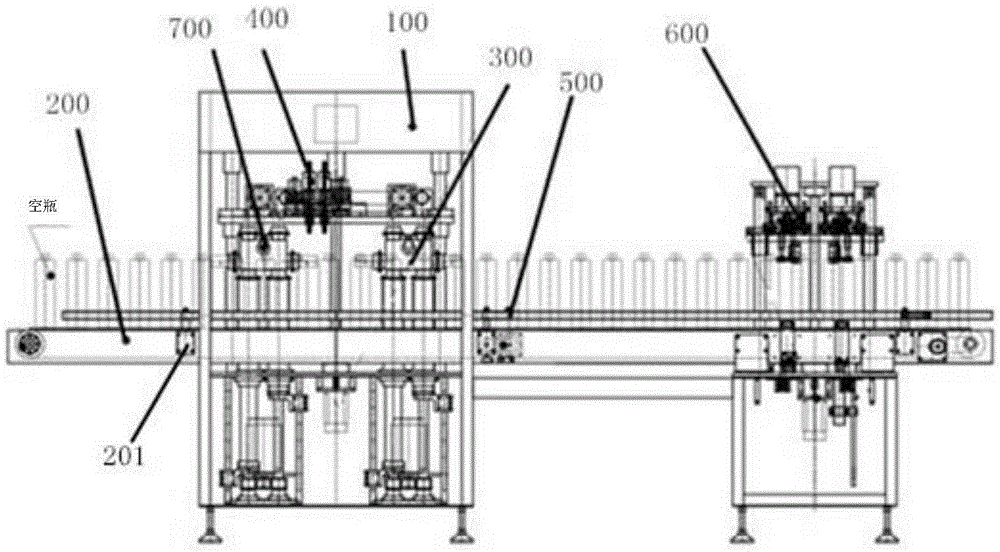

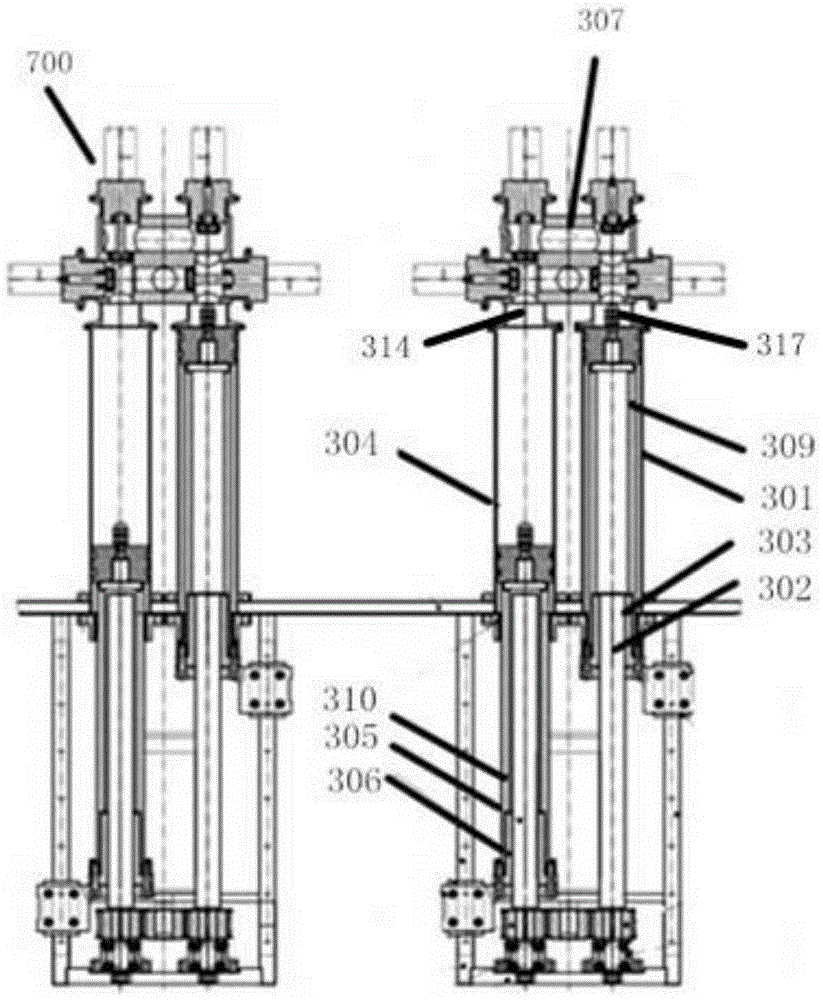

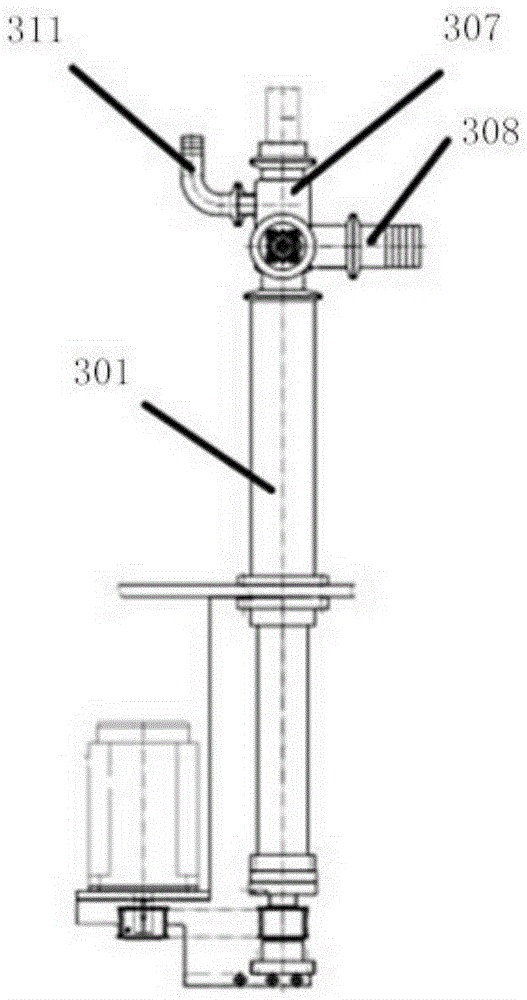

[0041] This embodiment includes a control system 100 , a conveying device 200 , a first double-cylinder filling valve body 300 , a second double-cylinder filling valve body 700 and a double-head asynchronous filling nozzle 400 .

[0042] After starting, the conveying device 200 is driven by a stepping motor to drive the empty bottles placed above to advance, such as Figure 4 and Figure 5 As shown, when the first filling detection sensor 402 detects an empty bottle, the servo motor starts to drive the first filling nozzle 401 on the first slider slide rail 405 to run synchronously with the movement speed of the empty bottle, as Figure 6 As shown, at the same time, the filling nozzle lifting device 406 drives the connected first filling nozzle 401 to press down, and the first gripper 408 on the first filling nozzle 401 clamps and positions the empty bottle nozzle to realize filling while walking Loading action; since there are two parallel slide rails in the same vertical pl...

Embodiment 2

[0051] This embodiment includes a control system 100 , a conveying device 200 , a first double-cylinder filling valve body 300 , a second double-cylinder filling valve body 700 and a double-head asynchronous filling nozzle 400 .

[0052] After starting, the conveying device 200 is driven by a stepping motor to drive the empty bottles placed above to advance, such as figure 1 , Figure 4 and Figure 5 As shown, the empty bottle detection sensor 201 detects the passing empty bottle, calculates the time t1 when the empty bottle moves to the first filling nozzle with the moving speed of the conveying device, and the time t2 when the next empty bottle moves to the second filling nozzle; after t1 time Afterwards, the servo motor starts to drive the first filling nozzle 401 on the first slide block slide rail 405 to run synchronously with the speed of the empty bottle, as Figure 6 As shown, at the same time, the first gripper 408 on the first filling nozzle 401 clamps and position...

Embodiment 3

[0054] The fully automatic filling line of this embodiment, on the basis of the structure of Embodiment 1, also includes a guardrail device 500, such as Figure 4 The shown guardrail device 500 utilizes the forward and reverse principle of the right-angle installation of the bevel gear 504 to rotate the drive shaft 501 to adjust and drive the swing arm 502 to open or close to clamp the bottle body.

[0055] Preferably, a guardrail 503 is connected to the clamping end of the swing arm, and the bottle body is clamped by opening or closing the guardrail 503 .

[0056] Preferably, a pressure sensor is provided on the guardrail 503, and the rotation angle of the gear 504 is automatically adjusted through the feedback signal of the pressure sensor, so as to realize adaptive clamping of bottles of different sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com