Modular internal circulation floatation-filtration device

A filtration device and internal circulation technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of uniform distribution of porosity, improvement of water production rate, and improvement of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

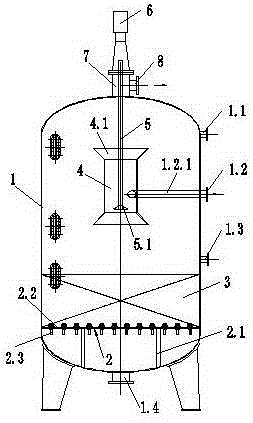

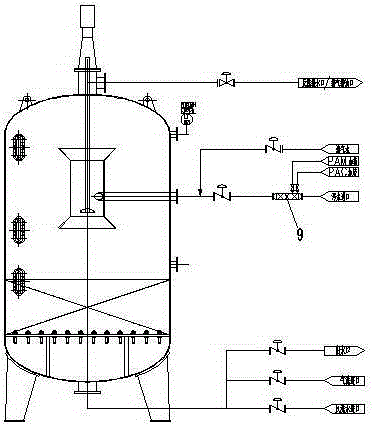

[0017] Embodiment 1: a modularized internal circulation air flotation filter device, comprising a cylinder 1, the side wall of the cylinder 1 is sequentially provided with a liquid level gauge port 1.1, a water inlet 1.2, a pressure transmitter port 1.3, a cylinder A water outlet 1.4 is provided at the bottom of the body 1, and a packing support 2 is provided near the bottom of the cylinder body 1. The packing support 2 includes a vertical support plate 2.1 and a horizontal perforated plate 2.2, and a long handle filter head is provided in the hole of the perforated plate 2.2. 2.3, the perforated plate 2.2 is provided with a walnut shell filter material 3, the center of the cylinder body 1 is provided with a central cylinder 4, the upper and lower ports of the central cylinder 4 are set as a bell mouth 4.1, and the water inlet 1.2 is provided with a water inlet pipe 1.2.1 and a central cylinder 4 The side walls are connected tangentially, the central cylinder 4 is provided with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com