Superaltitude conversion truss lifting device

A conversion truss, ultra-high-altitude technology, applied in the direction of construction, building structure, building material processing, etc., can solve problems such as installation difficulties, and achieve the effect of high practicability, light weight, and convenient dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

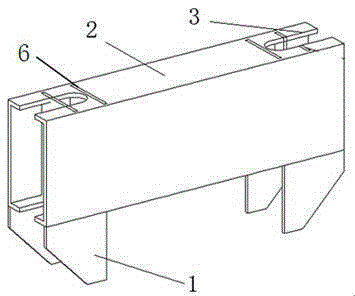

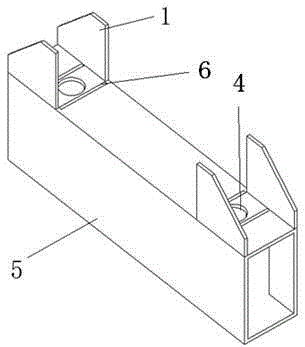

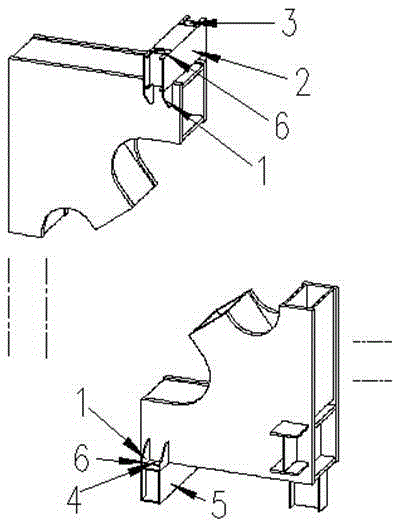

[0023] Such as Figure 1-Figure 2 The lifting device for a super high-altitude conversion truss includes an upper lifting beam 2 and a lower lifting beam 5 . Both ends of the upper lifting beam 2 are provided with upper reserved holes 3, the upper reserved holes 3 are arranged symmetrically with respect to the upper lifting beam 2, the upper reserved holes 3 run through the end edge of the upper lifting beam 2, and the two upper reserved holes The difference between the center distance between 3 and the width of the truss chord is 140mm. Both ends of the lower lifting beam 5 are provided with a lower reserved hole 4, which is symmetrically arranged with respect to the lower lifting beam 5, and the lower reserved hole 4 does not run through the end edge of the lower lifting beam 5, and the two lower reserved holes The difference between the center distance between the holes 4 and the width of the truss chord is 140mm. The reserved holes 3 on the upper part correspond to the r...

Embodiment 2

[0027] The structures and connection relations of a kind of ultra-high-altitude conversion truss lifting device in this embodiment are the same as those in Embodiment 1, and the different technical parameters are:

[0028] 1) The difference between the center distance between the two upper reserved holes 3 and the width of the truss chord is 170mm;

[0029] 2) The difference between the center distance between the two lower reserved holes 4 and the width of the truss chord is 170mm;

[0030] 3) The height of the lifting beam fixing piece 1 is 350mm, and the thickness is 20mm.

Embodiment 3

[0032] The structures and connection relations of a kind of ultra-high-altitude conversion truss lifting device in this embodiment are the same as those in Embodiment 1, and the different technical parameters are:

[0033] 1) The difference between the center distance between the two upper reserved holes 3 and the width of the truss chord is 200mm;

[0034] 2) The difference between the center distance between the two lower reserved holes 4 and the width of the truss chord is 200mm;

[0035] 3) The height of the lifting beam fixing piece 1 is 400mm, and the thickness is 25mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com