Dotted groove type optical fiber cladding surface Bragg raster

A technology of optical fiber cladding and dot-shaped grooves, which is applied in the direction of grating fiber, cladding fiber, optical waveguide and light guide, etc., can solve the problems of poor control of the process, reduce the mechanical strength of FBG, and difficult operation, and achieve low temperature/strain Cross-sensitivity effect, obvious birefringence effect, and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

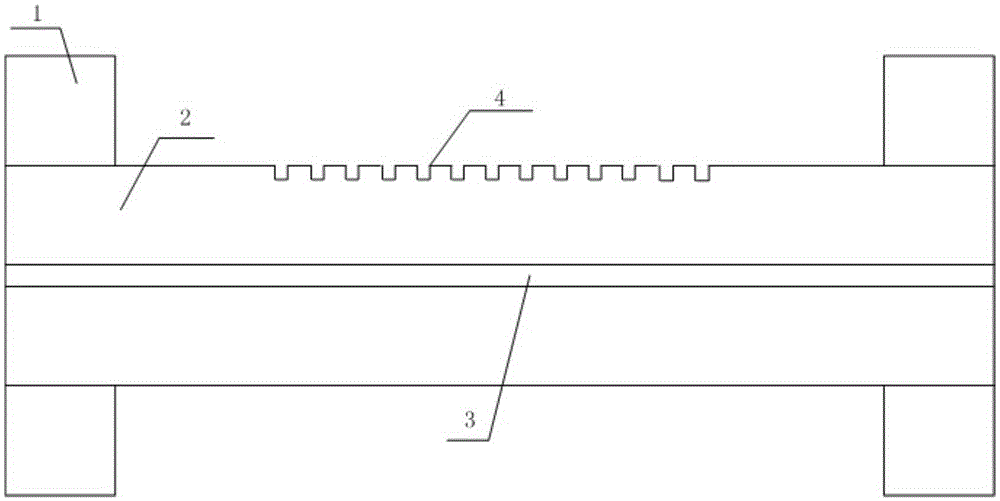

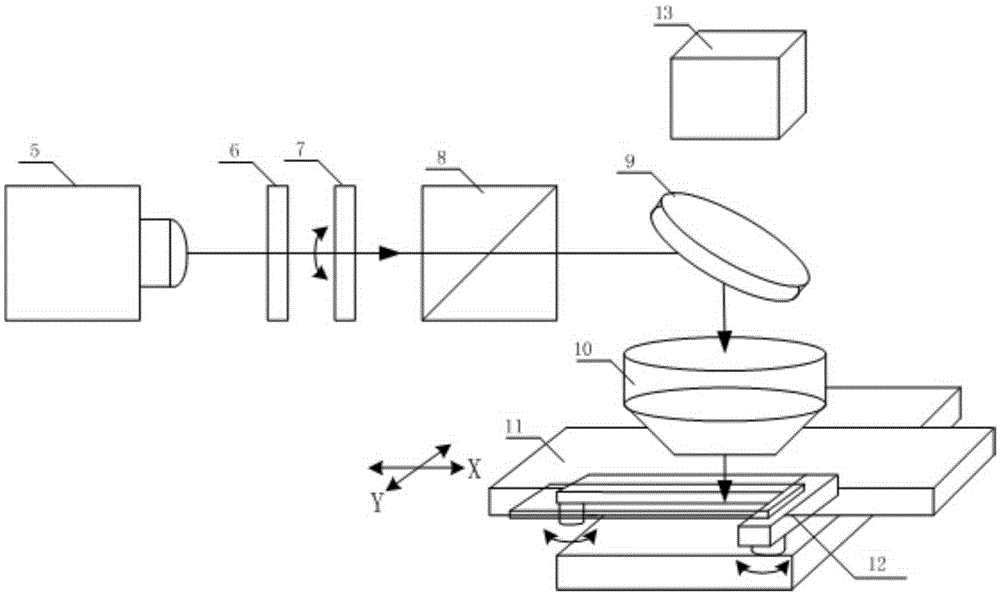

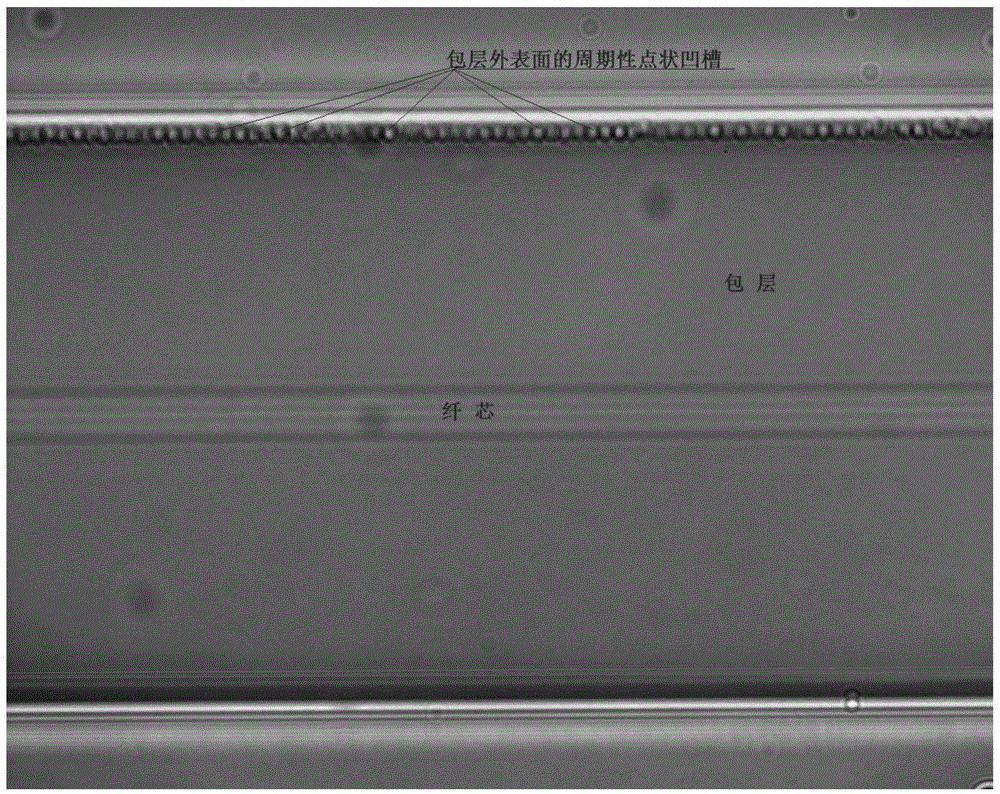

[0016] see figure 1 , a Bragg grating on the surface of a point-shaped groove-type fiber cladding, comprising: a fiber coating 1, a fiber cladding 2, and an optical fiber core 3; the fiber cladding surface Bragg grating 4 is arranged on the fiber cladding 2 of a single-mode fiber The outer surface of the fiber cladding surface; the fiber cladding surface Bragg grating 4 is composed of several point-shaped grooves, and several point-shaped grooves are distributed periodically along the axial direction of the optical fiber, and the outer surface of the optical fiber cladding is structurally Damage; the center points of all point-shaped grooves are located on a straight line, which is parallel to the central axis of the fiber; the groove depth of the point-shaped grooves is <0.5μm, and the groove width is less than half of the period of the Bragg grating on the surface of the fiber cladding; the The length of the Bragg grating on the surface of the fiber cladding is between 1 mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com