Double-sheath structured degaussing cable

A degaussing cable and double-layer sheath technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of low service life of cross-linked polyethylene materials, inconvenient cable laying and use, poor cable performance, etc. , to achieve the effects of good performance, light weight and strong self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

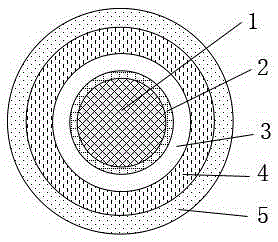

[0018] Such as figure 1 The degaussing cable with a double-layer sheath structure shown includes a copper conductor 1 arranged at the center of the cable, an isolation tape 2 is extruded outside the copper conductor 1, and a double-layer co-extrusion method is used to extrude the insulation tape 2 separately. The rubber insulating layer 3 and the rubber inner sheath 4 are finally extruded outside the rubber inner sheath with a thickness of 0.375-0.525mm and the outer sheath 5 is made of polyurethane with hydrolysis resistance added. The cable structure adopts the inner sheath + The double-layer sheath structure of the outer sheath is characterized in that the outer sheath is made of polyurethane material. Compared with the existing technology, the outer sheath is made of polyurethane, and its production process is simple. Linking can improve production efficiency and reduce the impact of radiation crosslinking on operators;

[0019] In order to better improve the cable, a hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com