Optical fiber composite medium-voltage cable

A fiber optic composite and cable technology, which is applied in the direction of insulated cables, communication cables, twisted/quad-stranded cables, etc., can solve the problem of not having the ability to transmit optical signals, it is difficult to realize the integration of power grids, and it cannot meet the requirements of intelligence Medium-voltage power network optical fiber communication requirements and other issues, to achieve the effect of reducing maintenance costs and improving fault response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

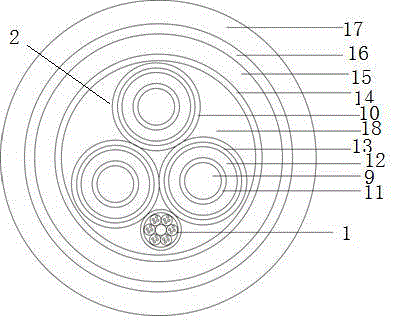

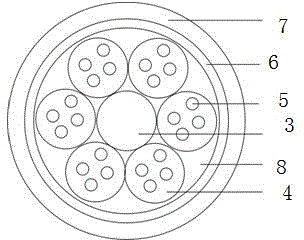

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] The labels in the drawings are as follows: 1 cable core, 2 optical cable unit, 3 FRP optical cable strengthening core, 4 optical fiber loose tube, 5 optical fiber, 6 water blocking tape, 7 electric tracking resistant sheath, 8 water blocking yarn, 9 Conductor, 10 metal shielding layer, 11 conductor shielding layer, 12 insulation layer, 13 insulation shielding layer, 14 tape layer, 15 isolation sleeve, 16 armor layer, 17 outer sheath layer, 18 filling rope.

[0012] An optical fiber composite medium-voltage cable according to the present invention differs from the prior art in that the cable is composed of an outer cladding and an inner core, and the inner core is composed of at least two cable cores and an optical cable unit. The outer cladding is composed of a tape layer, an insulating sleeve, an armor layer and an outer sheath layer; the center...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com