Photon chip packaging structure based on grating interface, and manufacturing method for photon chip packaging structure

A photonic chip and packaging structure technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of poor heat dissipation performance, complex process, poor performance of photonic chips, etc., to improve heat dissipation effect, Simple process, solve the effect of poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

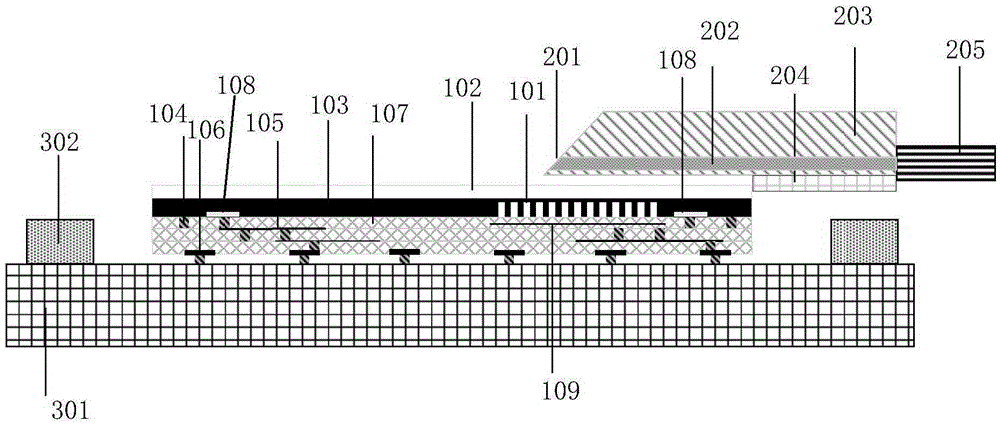

[0034] In order to solve the technical problems of poor performance of the photonic chip, complicated process and poor heat dissipation performance caused by the integration technology in the prior art, the present application provides a photonic chip packaging structure based on a grating interface. Such as figure 1 As shown, the photonic chip packaging structure based on the grating interface includes: an optoelectronic chip, an interconnection medium, a substrate 301 and an optical fiber coupling structure.

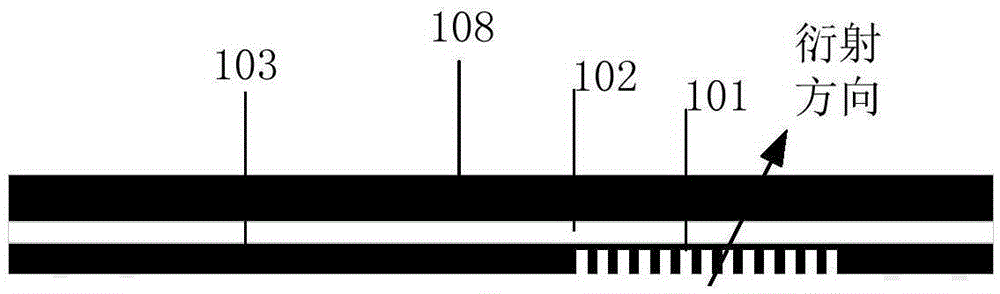

[0035] The optoelectronic chip includes an optoelectronic device (light modulator, detector, etc.) 108, a buried oxygen layer 102, a top silicon 103 and a back reflection grating 101 arranged on the top silicon 103.

[0036] The interconnection medium includes a multilayer dielectric layer 107 and an interconnection metal 105 arranged in the dielectric layer 107 for connecting the multilayer dielectric layer 107. Specifically, in this embodiment, the multi-layer dielectric ...

Embodiment 2

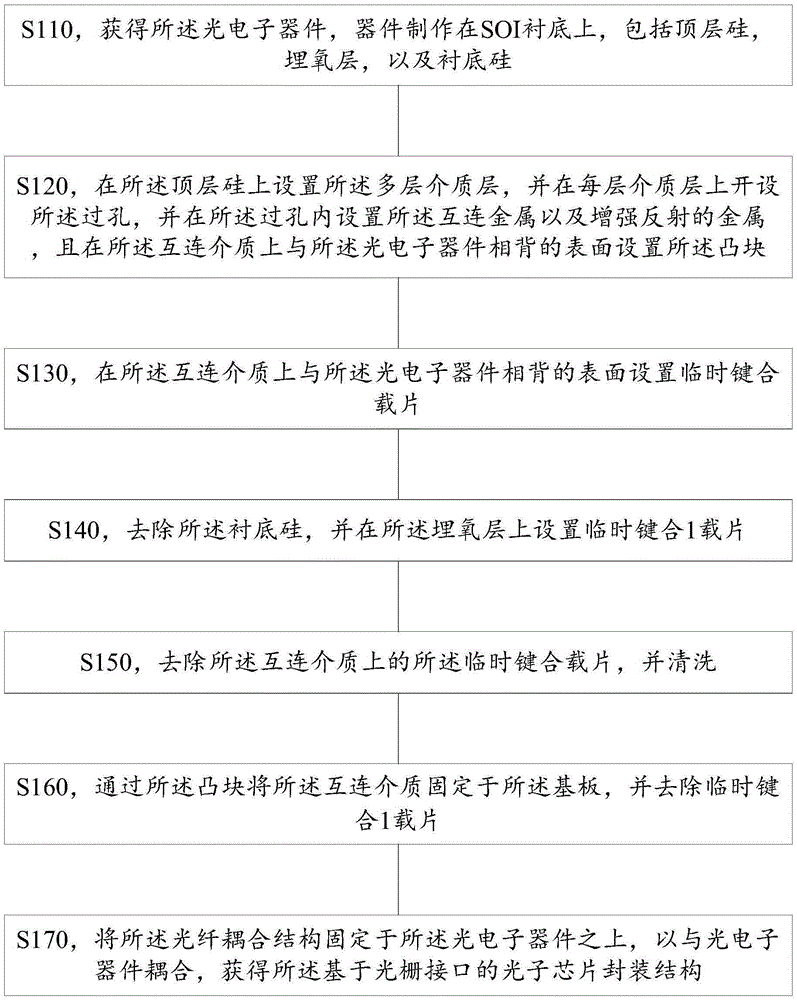

[0043] Based on the same inventive concept, the present application also provides a manufacturing method of a photonic chip packaging structure based on a grating interface. The manufacturing method is used to manufacture the photonic chip packaging structure based on a grating interface in the first embodiment. Such as figure 2 As shown, the manufacturing method includes the following steps:

[0044] Step S110, such as image 3 As shown, the optoelectronic chip is obtained, and a substrate silicon 108 is provided on the buried oxygen layer of the optoelectronic chip. The optoelectronic chip includes a buried oxygen layer 102, a top silicon 103, a back reflection grating 101 arranged on the top silicon 103, and an optoelectronic device.

[0045] Step S120, such as Figure 4-Figure 7 , A multi-layer dielectric layer 107 is provided on the top silicon 103, the via 104 is opened on each dielectric layer 107, and the interconnection metal 105 is provided in the via 104, and the enhanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com