Sunflower deseeding machine

A sunflower and deseed technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of sunflower seed damage, waste of labor, large separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

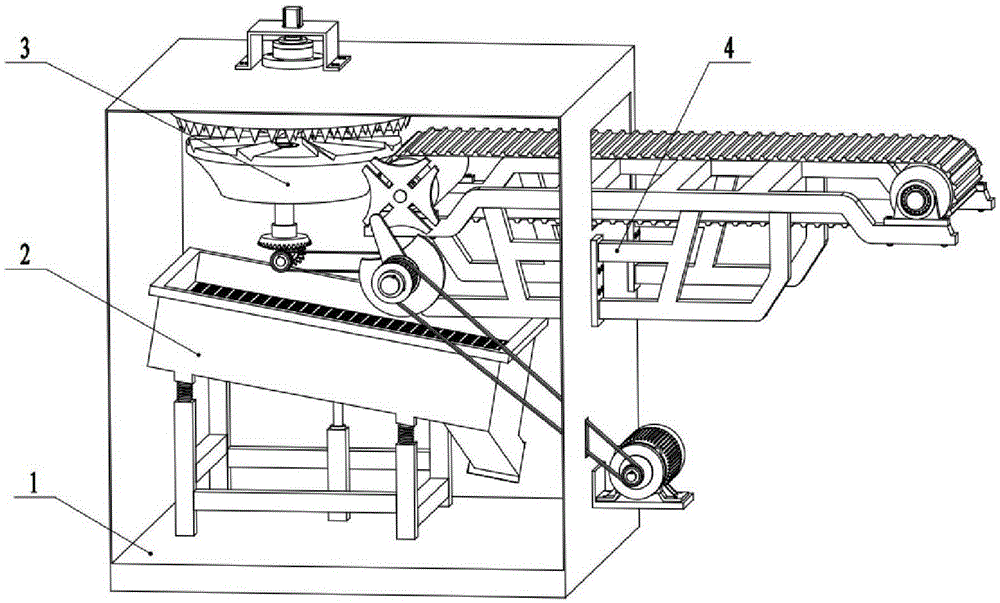

[0016] A sunflower seed remover is composed of a shell 1, a vibration screening device 2, a rotary peeling device 3 and a transmission feeding device 4, and is characterized in that: a vibration screening device 2 is installed on the inner bottom of the shell 1, and a rotary peeling device 3 Installed on the upper end of the casing 1 and above the vibration screening device 2 , the transmission feeding device 4 is installed on the right side of the casing 1 .

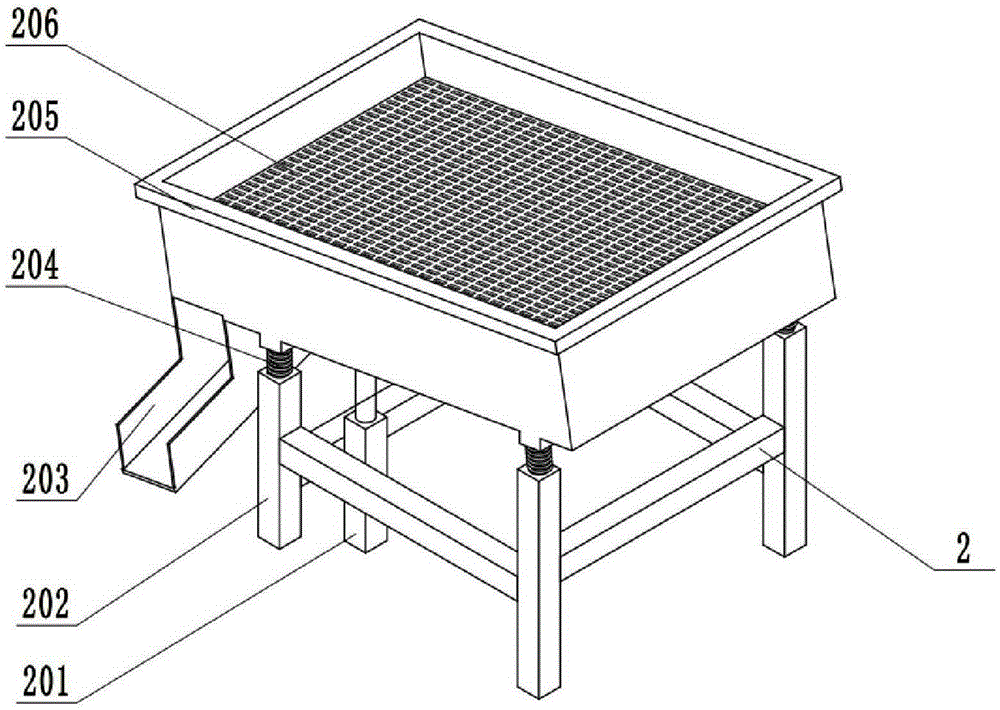

[0017] Described vibration screening device 2 is made up of cylinder 201, support frame 202, seed outlet 203, spring 204, vibrating box body 205 and screen cloth 206, is characterized in that: cylinder 201 is installed in the bottom of vibrating box body 205, and spring 204 Installed on the support frame 202, the vibration box body 205 is installed on the support frame 202 by the spring 204, the lower end of the vibration box body 205 has a seed outlet 203, and the screen cloth 206 is installed in the middle of the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com