Punching and bending mold

A mold and bending technology, applied in the direction of perforating tools, forming tools, manufacturing tools, etc., can solve the problems of parts and products that cannot be automatically pushed out, threats to worker safety, and low productivity, so as to achieve simple structure and improve personal safety factor , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with accompanying drawing.

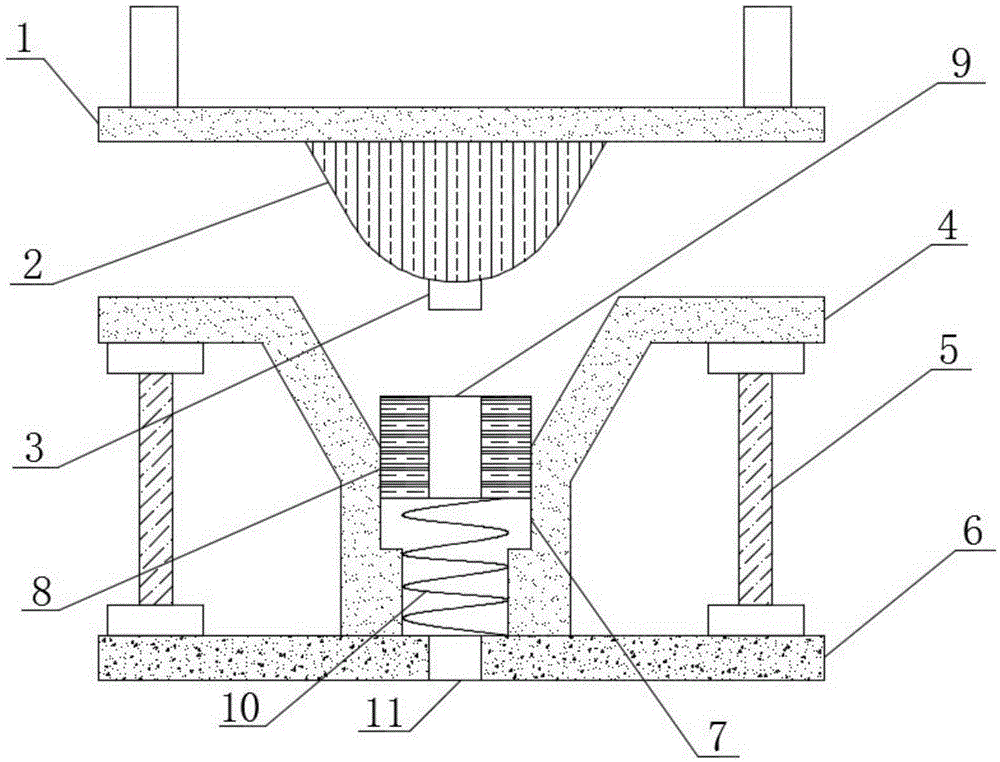

[0016] see figure 1 , the present invention provides a technical solution: a stamping and bending die, including an upper template 1 and a lower template 4, the lower side of the upper template 1 is fixedly connected with a punch 2, the section of the punch 2 is arc-shaped, and the convex The diameter of mold 2 is 15 centimetres, and punch 2 can process the upper end surface of part into required shape, and the lower side of punch 2 is fixedly connected with punching blade 3, and punching blade 3 is cylindrical, and punching blade 3 The diameter is 1.5 centimeters, and the lower formwork 4 is located at the lower side of the upper formwork 1, and the left and right sides of the lower part of the lower formwork 4 are fixedly connected with the bottom plate 6 through the fixing studs 5, and two sets of fixing studs 5 are used to fix, which can increase The stability of the lower template...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com