Copper-clad plate hydroforming device

A technology of hydroforming and copper-clad laminates, which is applied in lamination devices, lamination, and control lamination, etc., can solve the problems of high molding pressure, poor uniformity, and high product warpage, and achieve reduced resin curing and low warpage Small, less prone to white spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

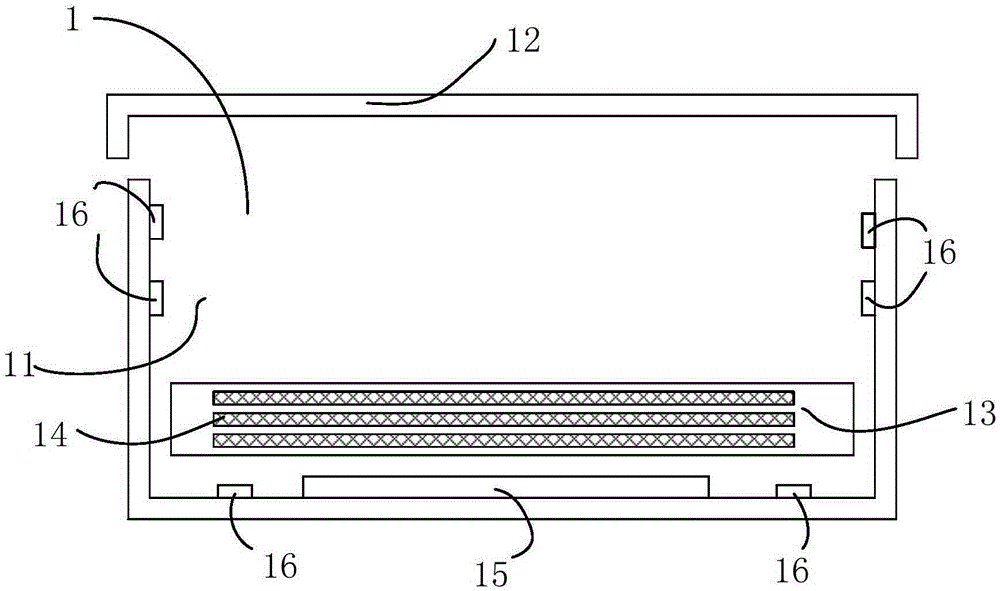

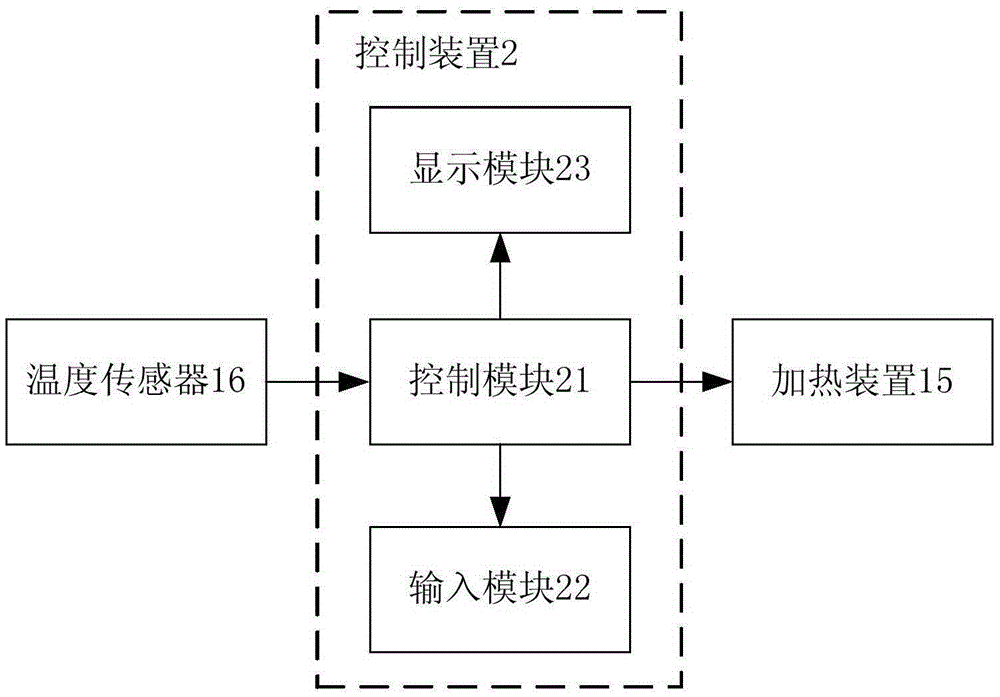

[0023] In order to overcome the shortcomings of the prior art, please refer to figure 1 and figure 2 , shown is a schematic structural diagram of a hydroforming device for a copper clad laminate provided by an embodiment of the present invention, including a pressing container 1 and a control device 2 ( figure 1 (not shown), the press-fit container includes a press-fit container body 11 and a container cover 12 made of sturdy, wear-resistant and corrosion-resistant cast steel materials, and the press-fit container body 11 and the container cover 12 have a tight fit with each other. Closed structure, the container cover 12 is closed to form a closed space, which can ensure that the lamination container is in a closed state during the lamination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com