Thermoplastic prepreg prepared through continuous laminating method and method thereof

A thermoplastic and prepreg technology, used in lamination, lamination devices, lamination auxiliary operations, etc., can solve problems such as low production efficiency, achieve the effect of small fiber damage, ensure stability, and improve product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

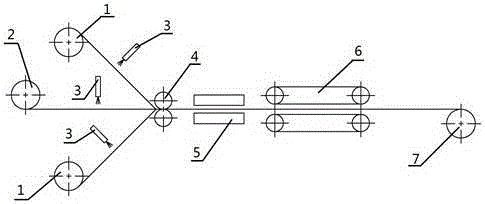

[0070] The selected density is 0.949g / cm 3 , A high-density polyethylene resin film matrix with a thickness of 0.0458mm and a width of 400mm, electronic grade glass fiber cloth 7628 as a continuous reinforcement material, and a control glue content of 30%;

[0071] Set the temperature of the impurity removal and drying nozzle 3 to 150°C, and use hot air to process the raw materials;

[0072] The linear velocity of the orientation roller 4 is set to 0.99m / s, and the pressure is set to 0.4MPa;

[0073] The temperature of the preheating device 5 is set to 170°C;

[0074] The linear velocity of the continuous laminating device 6 is 1m / s, the initial pressure is set to 0.8MPa, the pressure gradient is set to 0MPa / m, the initial temperature is set to 230°C, the heating and pressure impregnation section temperature rise gradient is 0°C / m, cooling and desorption The temperature gradient of the mold section is -20℃ / m;

[0075] The linear speed of the winding device 7 is set to 1.2 m / s, and the ...

Embodiment 2

[0077] The selected density is 1.32g / cm 3 , A polyetheretherketone film matrix with a thickness of 0.05mm and a width of 800mm, electronic grade glass fiber cloth 7628 as a continuous reinforcement material, and a control glue content of 40%;

[0078] Set the temperature of the impurity removal and drying nozzle 3 to 250°C, and use hot air to process the raw materials;

[0079] The linear speed of the orientation roller 4 is set to 1.98m / s, and the pressure is set to 0.4MPa;

[0080] The temperature of the preheating device 5 is set to 330°C;

[0081] The linear velocity of the continuous laminating device 6 is 2m / s, the initial pressure is set to 0.4MPa, the pressure gradient is set to 0.2MPa / m, the initial temperature is set to 360°C, the heating and pressure impregnation section heating gradient is 0°C / m, cooling The temperature gradient of the demoulding section is -20℃ / m, and the pressure is set to 1.0MPa;

[0082] The linear speed of the winding device 7 is set to 2.1 m / s, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com