Grain Harvesting Device for Drying Field

A drying yard and grain harvesting wheel technology, applied in the field of agricultural machinery, can solve the problems of low work efficiency, high labor intensity, and inability to adapt to modern agricultural production, and achieve the effect of novel design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

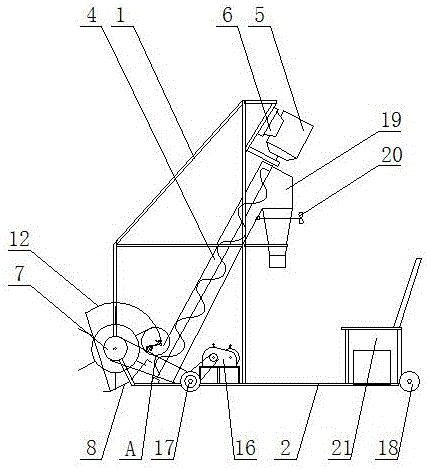

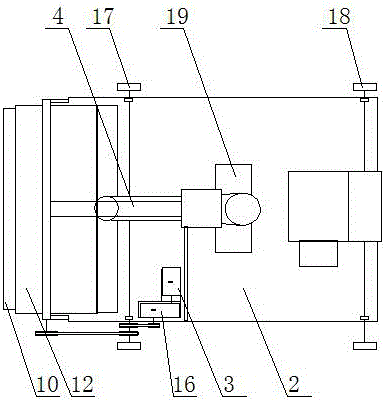

[0017] The drying field harvesting device includes a frame 1, a base plate 2, a working motor 3, a transmission auger 4, an auger motor 5 and a control box 6; round 7.

[0018] Grain harvesting wheel 7 is made of grain harvesting cylinder 9, grain harvesting sheet 10 and compression spring 11, and the circumference of grain harvesting cylinder 9 is radially provided with assembly groove, and grain harvesting sheet 10 is installed by compression spring 11 in the assembly groove; One end of the piece 10 extends to the outer end of the fitting groove. One end of the compression spring 11 is fixed on the bottom of the assembly groove, and the other end of the compression spring 11 is connected with the grain harvesting sheet 10 .

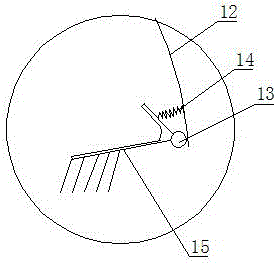

[0019] The grain harvesting wheel 7 top is equipped with protective cover 12 by frame 1; Via bearing pin 13 and spring 14 activities, clearing valley brush 15 is installed on protective shield 12;

[0020] Grain shoveling plate 8 is housed on the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com