Trolley Towed Arch Bridge Crane

A hoisting trolley and crane technology, applied in the directions of cranes, traveling mechanisms, load hanging components, etc., can solve the problems of high lifting height, low lifting height, unable to meet the special requirements of special workshops and users, and achieve positioning accuracy. High efficiency, high space utilization rate, and the effect of reducing civil construction costs

Active Publication Date: 2017-04-12

DALIAN HUARUI HEAVY IND CRANE CO LTD +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The shortcomings of traditional bridge cranes are: they cannot meet the special requirements of special workshops and users, such as the upper ceiling is arc-shaped, the lifting height of the middle part of the bridge frame is relatively large, and the lifting height of both ends is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

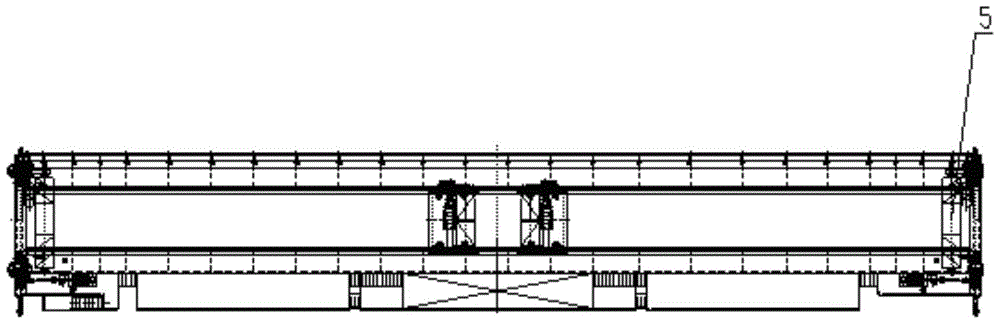

[0025] Embodiment 1 is a crane in which a set of trolley traction mechanism 5 drags a lifting trolley 1 , and trolley traction mechanism 5 is arranged at one end of bridge frame 2 .

Embodiment 2

[0026] Embodiment 2 is a crane in which two sets of trolley traction mechanisms 5 drag two lifting trolleys 1. The trolley traction mechanisms 5 are located at both ends of the bridge frame 2, and each set of trolley traction mechanisms drags one lifting trolley.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

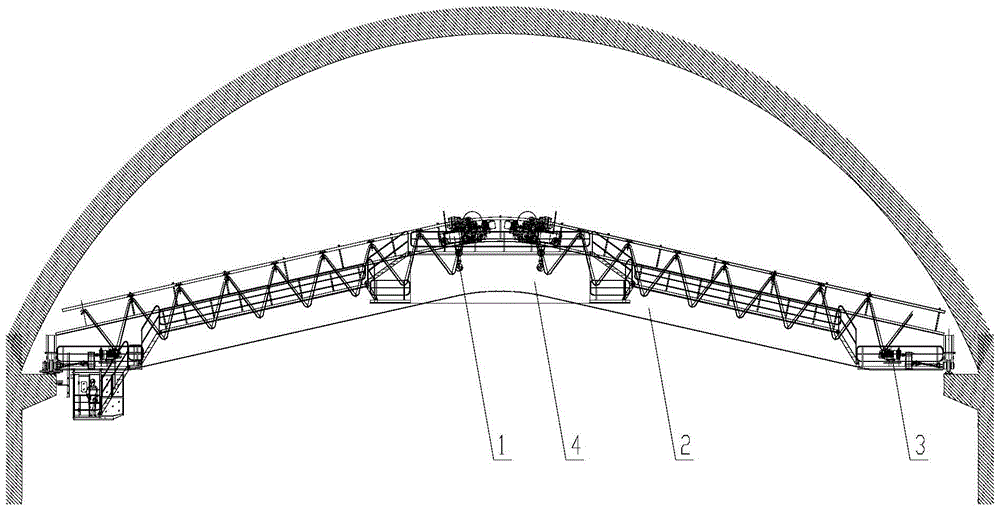

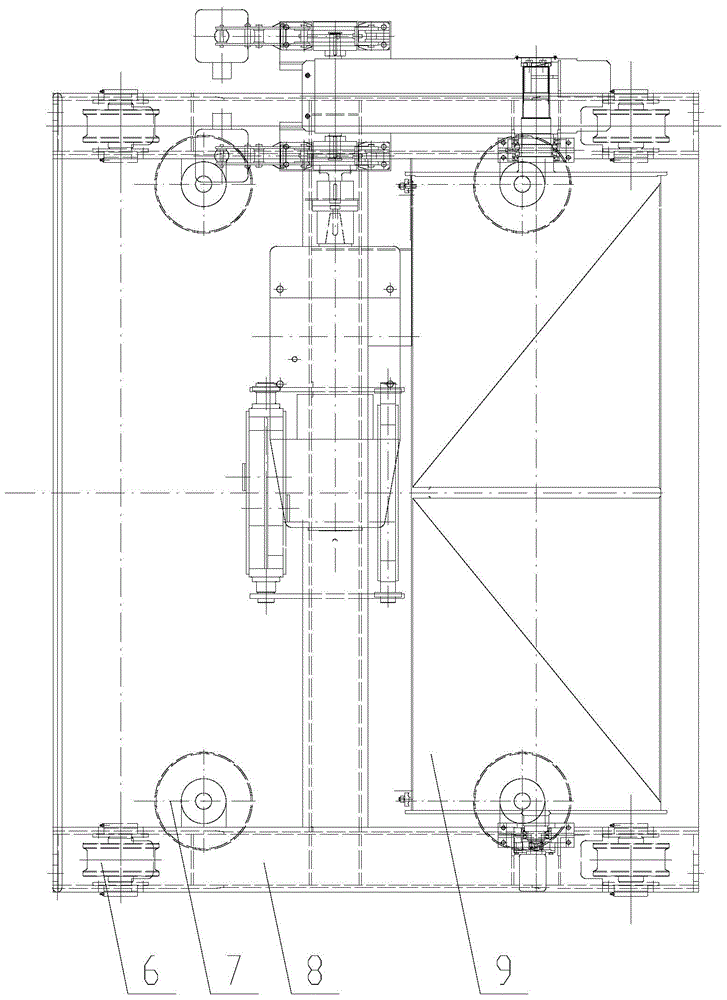

The invention discloses a traction type arch-bridge crane of a crane carriage. The traction type arch-bridge crane comprises the crane carriage, a crane span structure, a cart travelling mechanism and electrical control equipment, wherein the crane span structure is a four-beam structure which is arched in middle; a crane carriage travelling rail on the crane span structure is laid along an arched main beam upper cover; a trolley travelling mechanism of the crane carriage is a trolley traction mechanism which is arranged on the end part of the crane span structure; the trolley traction mechanism drives a winding drum set to rotate by virtue of a motor and a speed reducer, so that a steel wire rope wound on the winding drum set is synchronously collected and released to generate traction drive for driving the crane carriage to move. The traction type arch-bridge crane has the beneficial effects that: a mid-span part is high in lifting height, and a space utilization rate of a plant ceiling is increased; driving torque of the trolley traction mechanism is small, so that the crane carriage is safe and stable in operation, and relatively high in positioning precision; civil engineering construction cost can be reduced for a special occasion; and the design is compact, space usage is small and the space utilization rate is high.

Description

technical field [0001] The invention belongs to the technical field of cranes, in particular to bridge cranes. Background technique [0002] The bridge frame of the traditional bridge crane is a horizontal four-beam structure, and the lifting trolley runs back and forth on the horizontal bridge frame to lift objects. The shortcomings of traditional bridge cranes are: they cannot meet the special requirements of special workshops and users, such as the occasions where the upper ceiling is arc-shaped, the lifting height of the middle part of the bridge frame is relatively large, and the lifting height of both ends is low. Contents of the invention [0003] The object of the present invention is to provide a kind of bridge crane with arched main girder which is suitable for the occasions where the lifting height of the middle part is relatively large and the lifting height of both ends is relatively low. [0004] The technical solution of the present invention is: a hoisting...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B66C6/00B66C9/14

CPCB66C6/00B66C9/14B66C2700/01

Inventor 银长海李文杰辛宏辉胡耀翔李文静

Owner DALIAN HUARUI HEAVY IND CRANE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com