Stability control method and device for optical parameters of optical fiber perform

An optical fiber preform and stability control technology, which is applied to glass manufacturing equipment, manufacturing tools, etc., can solve the problems of not mentioning the influence of the uniformity of exhaust wind speed on the deposition efficiency of the preform surface, and achieve the consistency of control deposition, Consistent effect of deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

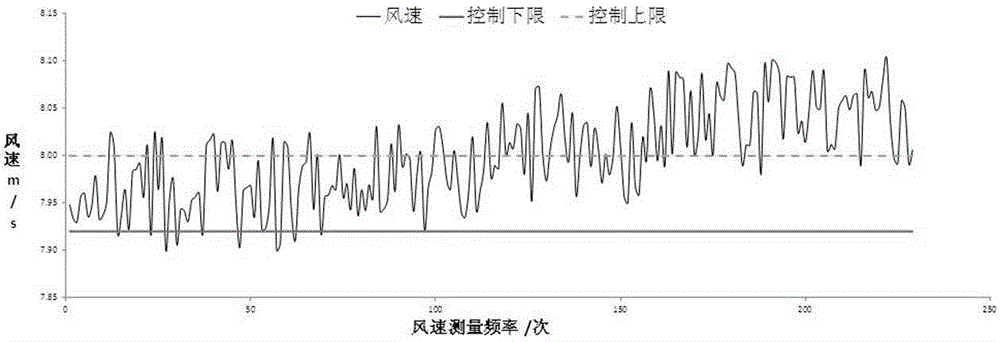

[0054] Turn on the wind speed detection and processor 8 to monitor the wind speed in real time, turn off the signal feedback function, and keep the initial position of the air valve opening of the exhaust pipe unchanged.

[0055] After the deposition, the results of the offset and deposition volume of each air duct are as follows:

[0056] Duct number 1# 2# 3# 4# 5# Initial wind speed m / s 7.98 8.00 7.99 8.00 7.98 End wind speed m / s 8.01 8.03 8.05 8.01 8.00 Offset ratio % 0.38 0.37 0.75 0.12 0.25 Preform Deposition Offset % 0.33 0.32 1.21 0.00 0.15 Preform Drawing Optical Parameters (MFD) Offset % 0.16 0.15 0.92 0.00 0.08

[0057] Among them, the deviation of the deposition amount of the optical fiber preform is judged based on the position of the 4# air duct with the minimum deviation of the wind speed. It can be seen that where the wind speed offset is relatively large, the deposition amount of the optical fib...

Embodiment 2

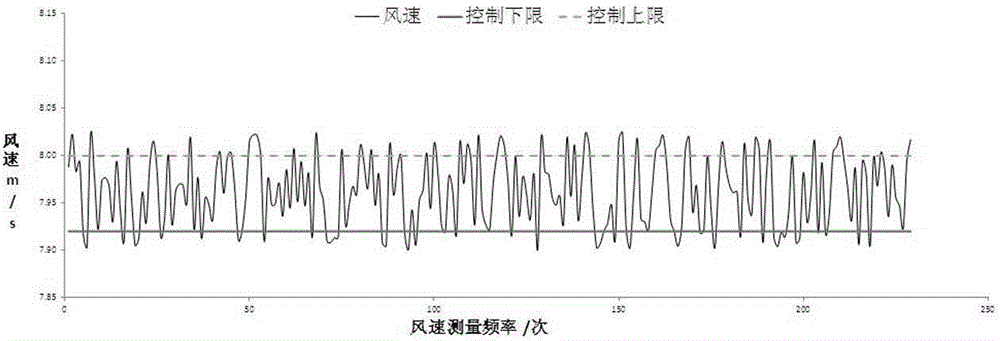

[0060] The wind speed detection and processor 8 are turned on for real-time wind speed monitoring, the signal feedback function is turned on, and the air valve opening of the exhaust pipe is automatically adjusted online.

[0061] After the deposition, the results of the offset and deposition volume of each air duct are as follows:

[0062] Types of 1# 2# 3# 4# 5# Initial wind speed m / s 7.98 8.00 7.99 8.00 7.98 End wind speed m / s 8.01 8.03 8.05 8.01 8.00 Offset ratio % -0.12 0.00 0.00 -0.12 0.12 Preform Deposition Offset % 0.08 0.00 0.01 0.06 0.01 Preform Drawing Optical Parameters (MFD) Offset % 0.05 0.00 0.00 0.03 0.01

[0063] Among them, the deviation of the deposition amount of the optical fiber preform is judged based on the position of the 2# air duct with the minimum wind speed deviation. It can be seen that the wind speed fluctuation is controlled at about 0.1%, the deposition amount of the optical f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com