Cold-processing technology of Al-Mg alloys at liquid nitrogen temperature region

A technology of cold working and liquid nitrogen, applied in the field of aluminum alloy sheet, can solve problems such as impact energy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

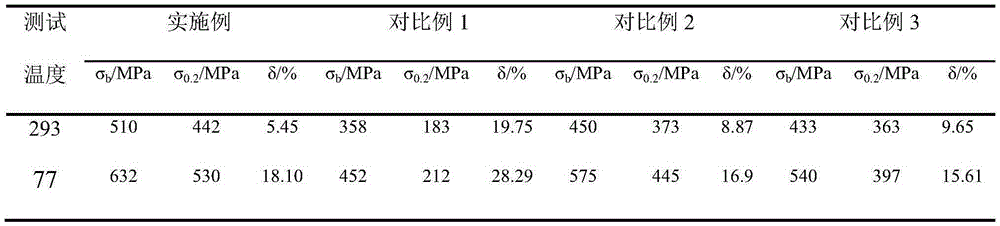

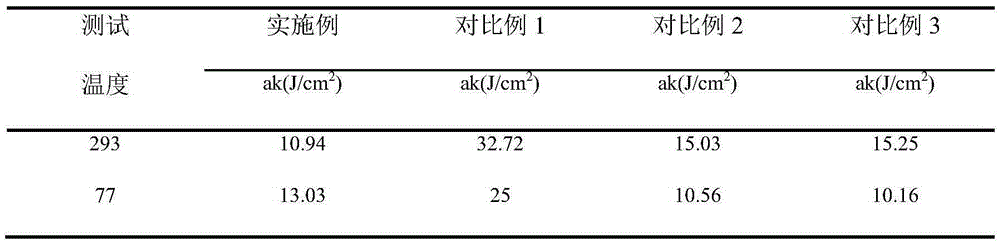

Examples

Embodiment

[0019] The weight percent content of the aluminum alloy plate is: Mg, 5.9%-6.2%; Mn, 0.3%-0.6%; Zn, 0.6%-0.9%; Zr, 0.1%-0.2%; Er, 0.1%-0.3% ; Unavoidable impurities ≤ 0.5%, the balance is Al. It is characterized in that, comprising the following steps:

[0020] (1) For the Er-containing aluminum alloy plate, heat the as-cast alloy at 470±20°C for 20 hours, then hot-roll it at a temperature of 410±20°C with a reduction of 90%, air-cool to room temperature, and have a thickness of 10mm. Recorded as H112.

[0021] (2) Submerge the hot-rolled plate obtained in step (1) completely in an incubator filled with liquid nitrogen for a period of time to cool the plate to the temperature of liquid nitrogen, and then quickly take out the cooled rolled plate from the liquid nitrogen at room temperature Carry out cold rolling, the reduction amount of each pass is 10%-15%, and after each pass is completed, the rolled plate is quickly put back into the incubator filled with liquid nitrogen a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com