Installation method of insulation boards used for assembly type refrigeration house

An installation method and thermal insulation board technology are applied in building thermal insulation materials, building material processing, building components, etc., and can solve problems such as poor air tightness, moisture-proof and waterproof performance, poor sealing between thermal insulation boards and ground bases, and high labor intensity. , to achieve good airtightness, moisture-proof and waterproof performance, meet the requirements of installation and splicing, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

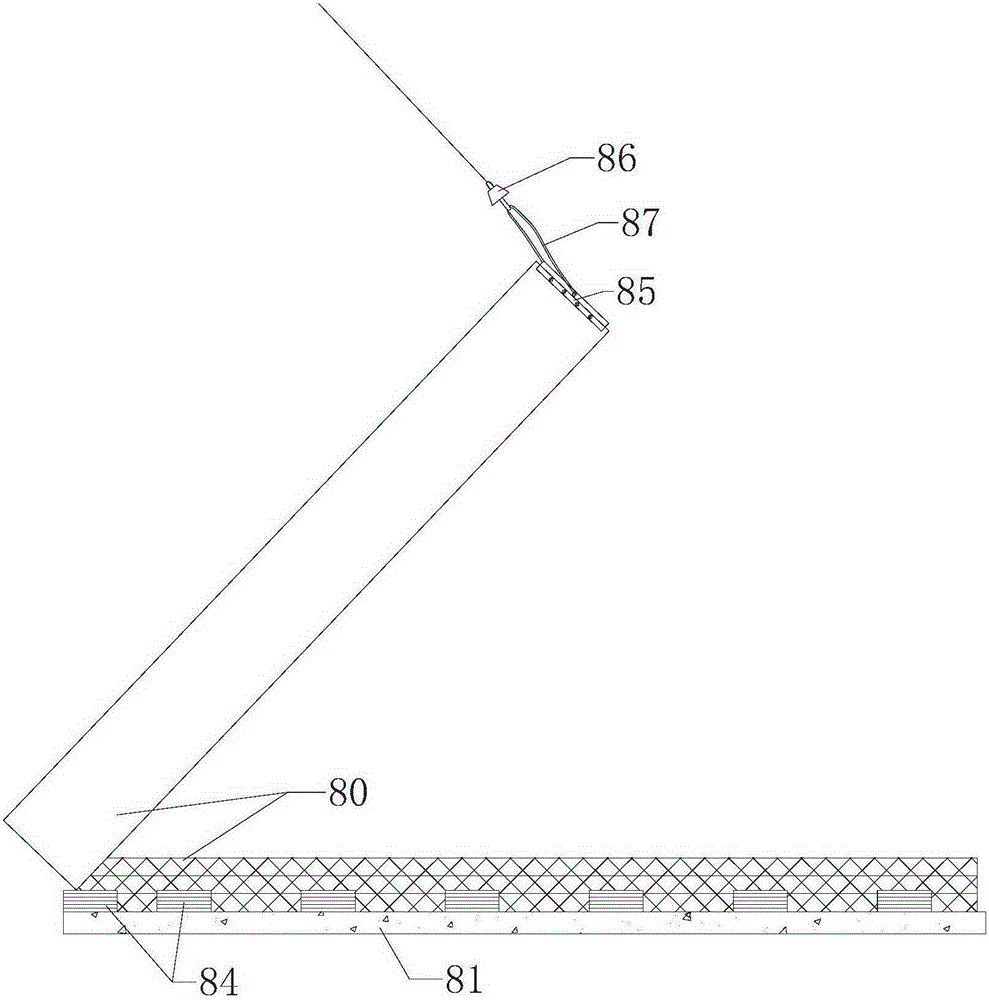

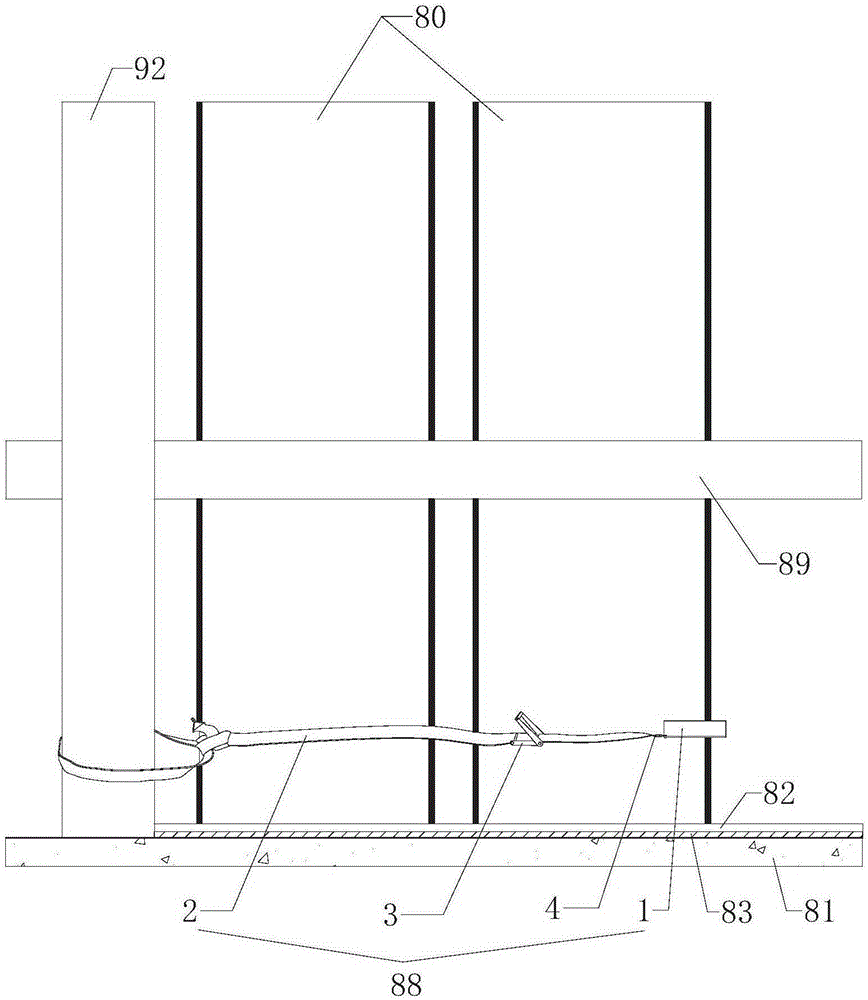

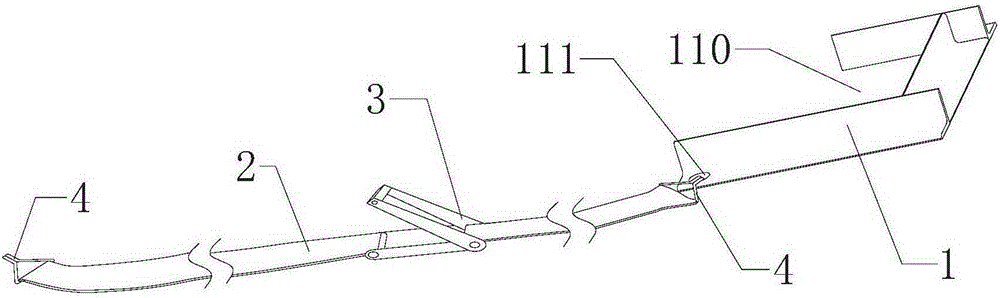

[0034] combine Figure 1 to Figure 11 , a method for installing insulation boards for a prefabricated cold storage (usually a prefabricated large-scale two-story steel structure cold storage), the prefabricated cold storage includes a steel structure skeleton, several transverse purlins, several insulation boards, positioning grooves, waterproof Vapor insulation coil;

[0035] The installation method includes the following steps:

[0036] 1', draw the layout diagram:

[0037] According to the structural elevation of the prefabricated cold storage, draw the corresponding layout diagram, and carry out specific installation according to the layout diagram.

[0038] 1. Horizontal setting-out positioning:

[0039] The installation position of the positioning groove body 82 is set out on the ground base layer 81 to form a positioning reference line; the positioning groove body 82 is a U-shaped positioning groove body.

[0040]2. Bedding waterproof and steam-proof coil:

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com