Multi-point multi-gallery energy-saving environmental-protection storage device and discharging method thereof

An energy-saving, environmentally friendly, and corridor-based technology, which is applied to large-capacity bulk material storage, building types, buildings, etc., can solve the problems of multi-point discharge bins, insufficient utilization of single-point discharge bins, and poor use effects, etc. problems, to achieve the effect of reducing material cost, optimizing material output time and resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

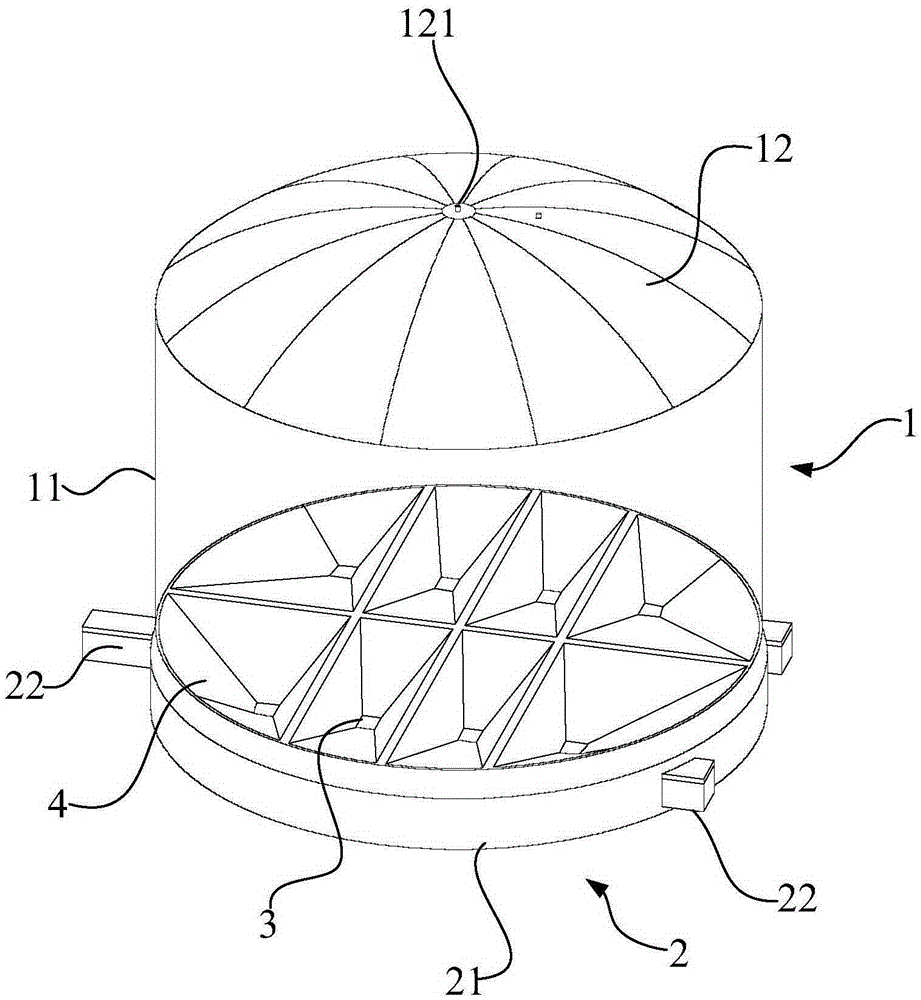

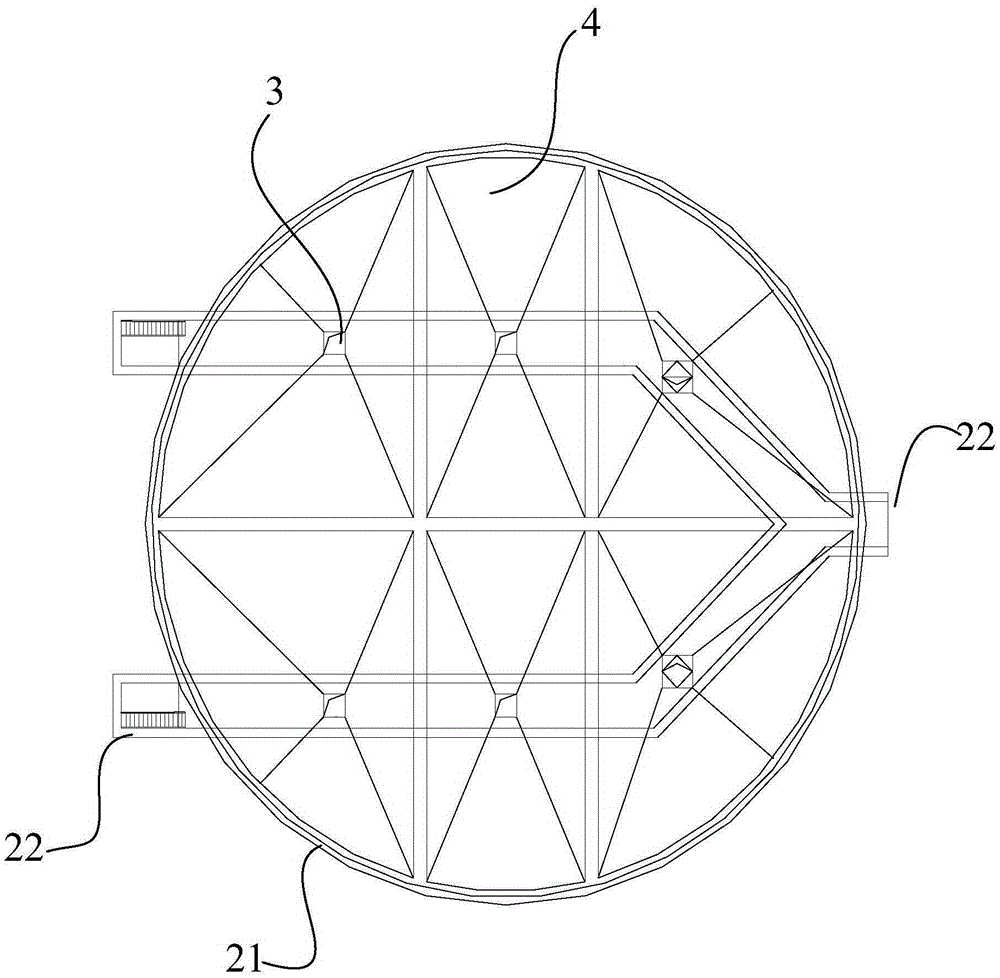

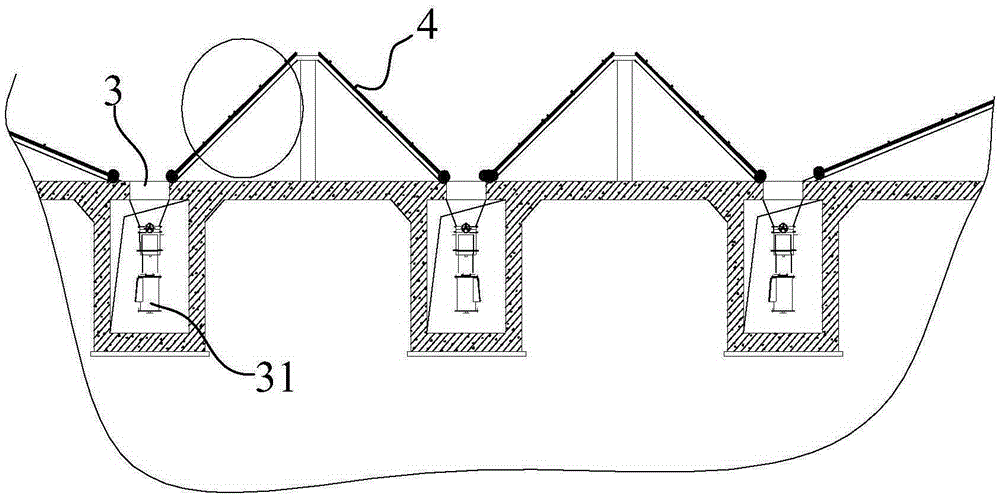

[0041] Example 1, such as figure 1 , figure 2 , image 3 As shown, this embodiment provides a multi-point multi-corridor energy-saving and environmentally friendly storage equipment, including a silo body 1 and an annular foundation 2 arranged under the silo body 1. The shape of the silo body 1 is cylindrical. The silo body 1 includes a cylindrical cylinder 11 and a silo roof 12 on the top of the cylinder 11. The shape of the silo roof 12 is a spherical shape, and a feed port 121 is arranged at the center of the silo roof 12. The entire silo The steel structure inside the main body 1 is kept stable, and the outlet 3 is evenly arranged at the bottom of the cylinder 11, and the outlet 3 is arranged at the bottom of the cylinder 11 in a row, and at least 2 rows are arranged at the bottom of the cylinder Outlet, at least 3 outlets are set for each outlet, and the outlets are arranged in parallel in a row. The main purpose of the row-like arrangement is to better cooperate with ...

Embodiment 2

[0048] Embodiment 2, this embodiment provides a method for discharging storage equipment with 6 discharge ports and 2 discharge corridors:

[0049] 1. First confirm whether the equipment other than the storage equipment is turned on, such as whether the power supply of the on-site equipment is connected, whether the manual gate valve at the unloading point at the bottom of the warehouse is in the open state, whether the elevator, chute, dust collector, and equipment used for the warehouse are opened. Whether the air source of the air compressor (such as the pulse valve of the dust collector, etc.) and other equipment have been operated. After confirmation, enter the operation of the gasification discharge system of the storage equipment.

[0050] 2. Opening, any one of the outlets (generally the outermost outlet is the opening point, that is, the outlet closest to the annular pouring edge) on the corresponding main air pipe (that is, above the first outlet corridor) Manual bu...

Embodiment 3

[0057] Embodiment 3, this embodiment provides a discharge method for storage equipment with 13 discharge ports and 3 discharge corridors, the difference from Embodiment 2 lies in the sequence of discharge, in this embodiment ,Such as Figure 7 As shown, first open the control valves No. 1, 8, and 9 of the discharge port, first open the pneumatic switch valve, and then open the electric flow control valve. To open the electric flow control valve, it is necessary to adjust the opening of the electric flow control valve. Open from small to large, monitor the discharge situation according to the current of the hoist motor, run the discharge stably for about 30 minutes, switch to discharge port No. 2, and close the discharge port No. 1 and No. 10 when switching between No. 7 and No. 10 No. 8 and No. 9 pneumatic switching valves, followed by closing the electric flow valve. After closing, open the pneumatic switching valves of No. 2, No. 7 and No. 10 feeding ports, and then open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com