Vertical and split type drying oven

A separate, drying furnace technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of long waste heat recovery route, high exhaust gas temperature, and reduced heat exchange efficiency, so as to shorten the waste heat recovery route , Efficiently heat the air and improve the effect of heat exchange efficiency

Inactive Publication Date: 2016-02-24

贵州遵义新佳裕食品有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, most of the general drying furnaces at home and abroad adopt a cylindrical integral structure, which has a short heat exchange process, high exhaust gas temperature, small heat exchange area, large volume, and low thermal efficiency; The hot air outlet is connected to the air inlet of the drying furnace for waste heat recovery. In this way, the waste heat recovery route is long and the loss of heat is large.

The equipment adopts a vertical structure. As the drying furnace will accumulate smoke and dust in the flue with the passage of time, it will affect the heat transfer capacity of the tube wall and reduce the heat transfer efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

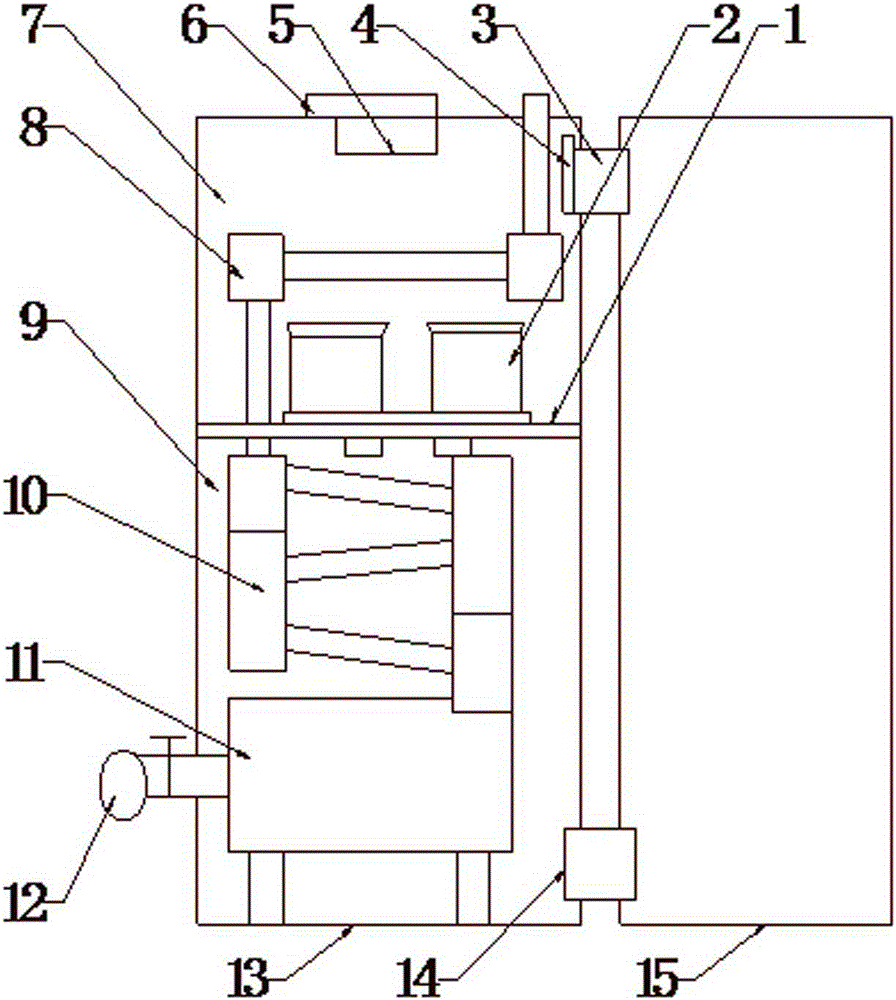

The invention discloses a vertical and split type drying oven in the technical field of equipment. The vertical and split type drying oven comprises a drying box and a hot-blast stove with a combustor at the bottom, an igniter is located outside the hot-blast stove and communicated with the combustor; the hot-blast stove and the drying box are arranged in parallel; a fan support for dividing the hot-blast stove into a preheating chamber and a heat exchange chamber is arranged inside the hot-blast stove; the fan support is provided with an axial flow fan; heat distribution pipelines are further arranged inside the hot-blast stove and distributed in a Z shape; the heat distribution pipelines comprise a heat exchange pipeline located in the heat exchange chamber and a preheating pipeline located in the preheating chamber; the heat exchange pipeline is communicated with the preheating pipeline; an air inlet with an air door is formed in the top of the hot-blast stove; an air outlet is formed in the lateral wall of the lower end of the heat exchange chamber; a hot air inlet is formed in the lateral wall of the lower end of the drying box; the air outlet is communicated with the hot air inlet. The vertical and split type drying oven improves the heat exchange efficiency, so that the beneficial effect of rapidly and efficiently heating air is achieved.

Description

technical field [0001] The invention relates to the technical field of drying equipment, in particular to a vertical split drying furnace. Background technique [0002] At present, most of the general drying furnaces at home and abroad adopt a cylindrical integral structure, which has a short heat exchange process, high exhaust gas temperature, small heat exchange area, large volume, and low thermal efficiency; The hot air outlet is connected to the air inlet of the drying furnace for waste heat recovery. This way the waste heat recovery route is long and the loss of heat is large. The equipment adopts a vertical structure. As the drying furnace will accumulate smoke and dust in the flue with the passage of time, it will affect the heat transfer capacity of the tube wall and reduce the heat transfer efficiency. Contents of the invention [0003] The present invention aims at the above-mentioned existing technical problems, and provides an energy-saving and high-efficiency...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F26B21/00F24H3/08

CPCF26B21/002F24H3/087

Inventor 程代松

Owner 贵州遵义新佳裕食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com