Cutter knife and knife head equipped with same

A blade and blade technology, used in grain processing and other directions, can solve problems such as labor and material loss, reduce energy consumption, simplify manufacturing processes, and prevent excessive regrinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

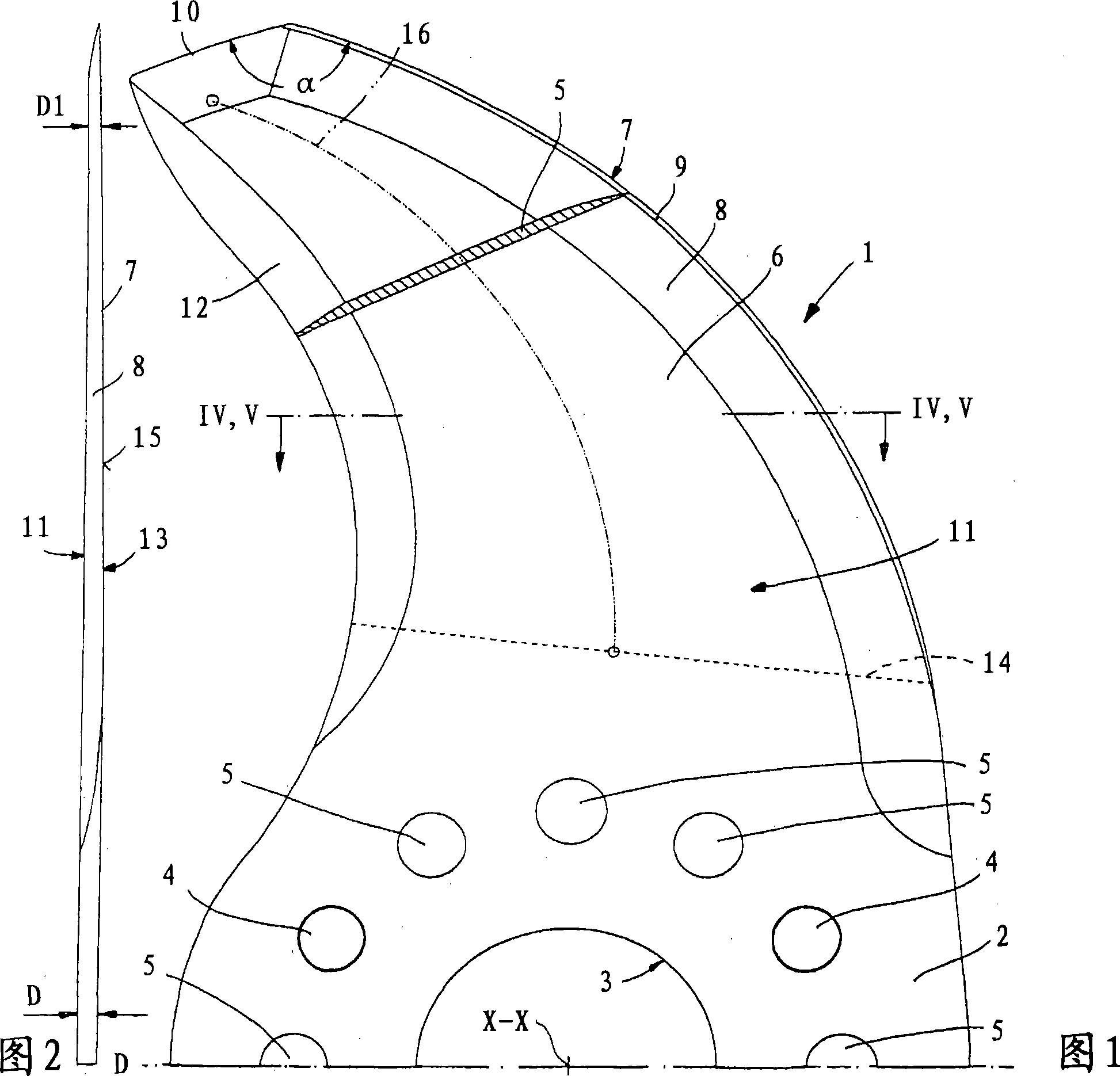

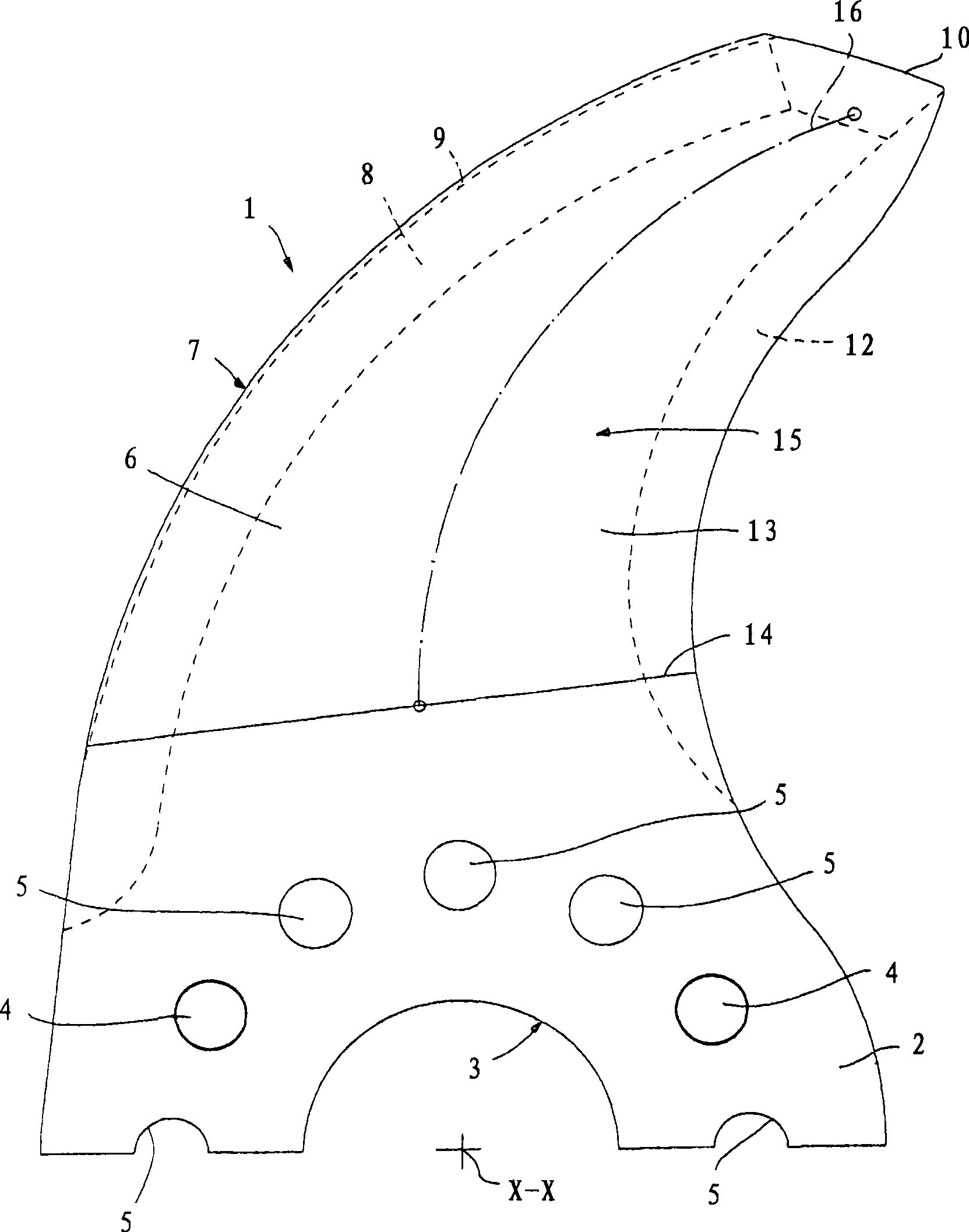

[0037]The chopping knife 1 comprises a semicircular clamping part 2 with a central hole 3 with an axis of rotation X-X, two centering holes 4 for inserting on a centering pin not shown in the figure and through holes 5. Stretch out sickle-shaped blade 6 from clamping part 2, blade outer side is a part circular arc blade 7, and blade inner side has wider blade facet 8 and outer side has narrower blade facet 9. Immediately following the outer extremity of the cutting edge 7 is a relatively blunt emulsified edge 10 with an obtuse angle α. On the same first side 11 where the blade 6 is visible, there is a relatively blunt curved back edge 12 .

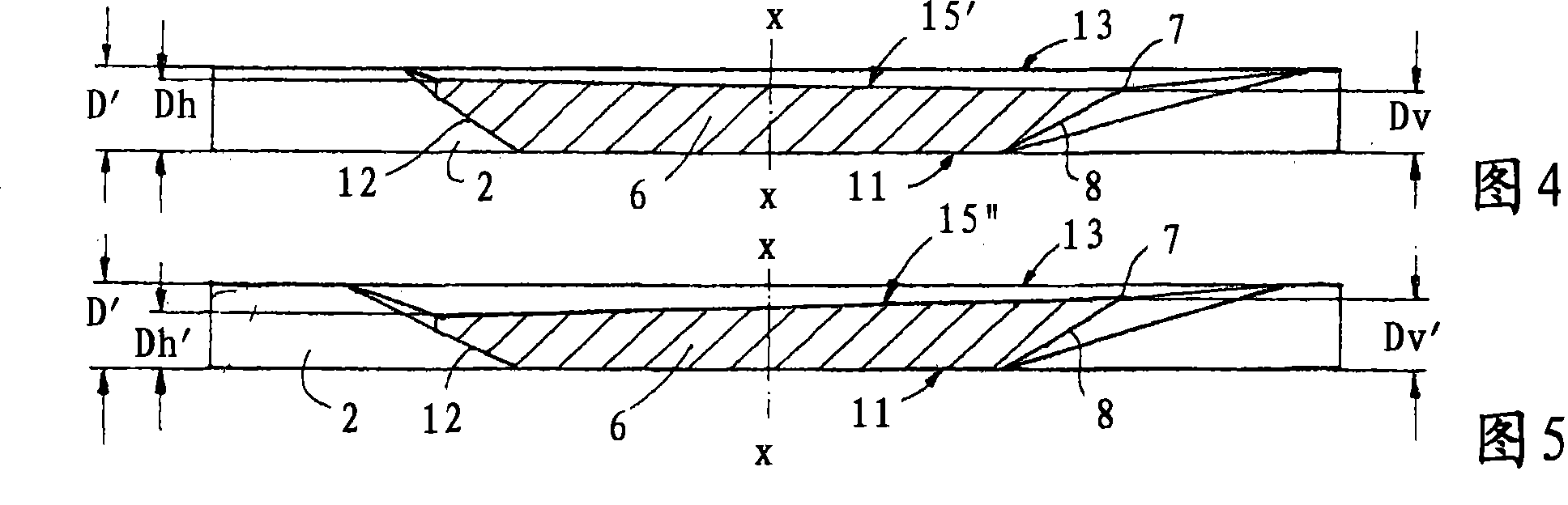

[0038] The chopping knife 1 extends in principle perpendicular to the axis of rotation X-X. The first side 11 of the blade 6 is in the same plane as the visible face of the clamping part 2 shown in FIG. 1 . The clamping portion 2 and the beginning of the blade 6 have the same thickness D (see FIG. 2 ). On the second side 13 (see attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com